Array multispectral optical filter and manufacturing method thereof

A production method and multi-spectral technology, applied in the direction of optical filters, etc., to achieve the effect of wide application range, reducing side lobes, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

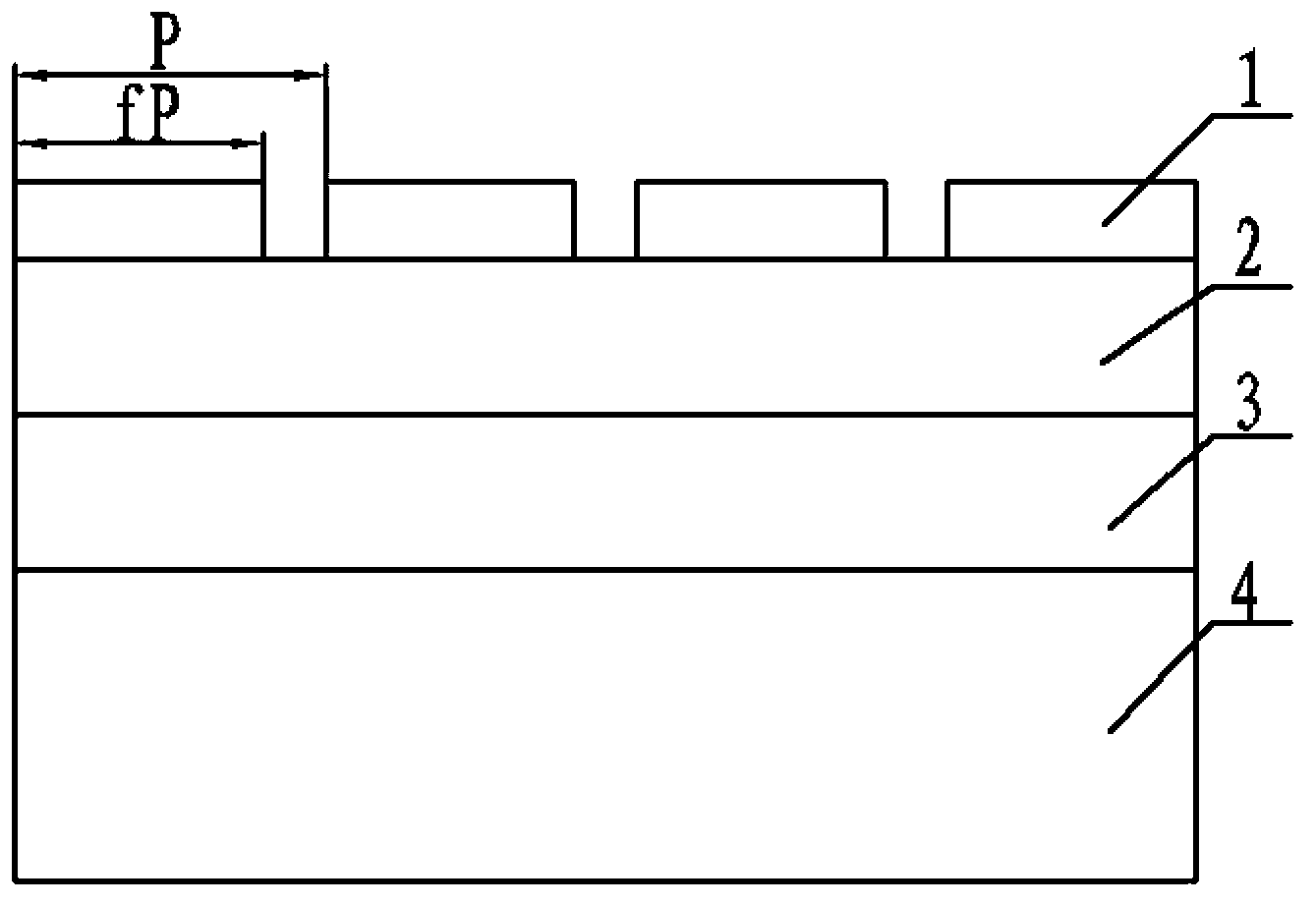

[0060] Aluminum (Al), which has high reflectivity (>90%) in the visible and infrared bands, is selected as the material of the two-dimensional metal grating layer. The buffer layer material is silicon dioxide (SiO 2 , refractive index n=1.46), the thickness is 0.1μm; the waveguide layer material is titanium dioxide (TiO 2 , refractive index n=2.5), the thickness is 0.1μm; the substrate is a quartz glass sheet (the main material is SiO 2 , Refractive index n=1.46).

[0061] Selection of various parameters:

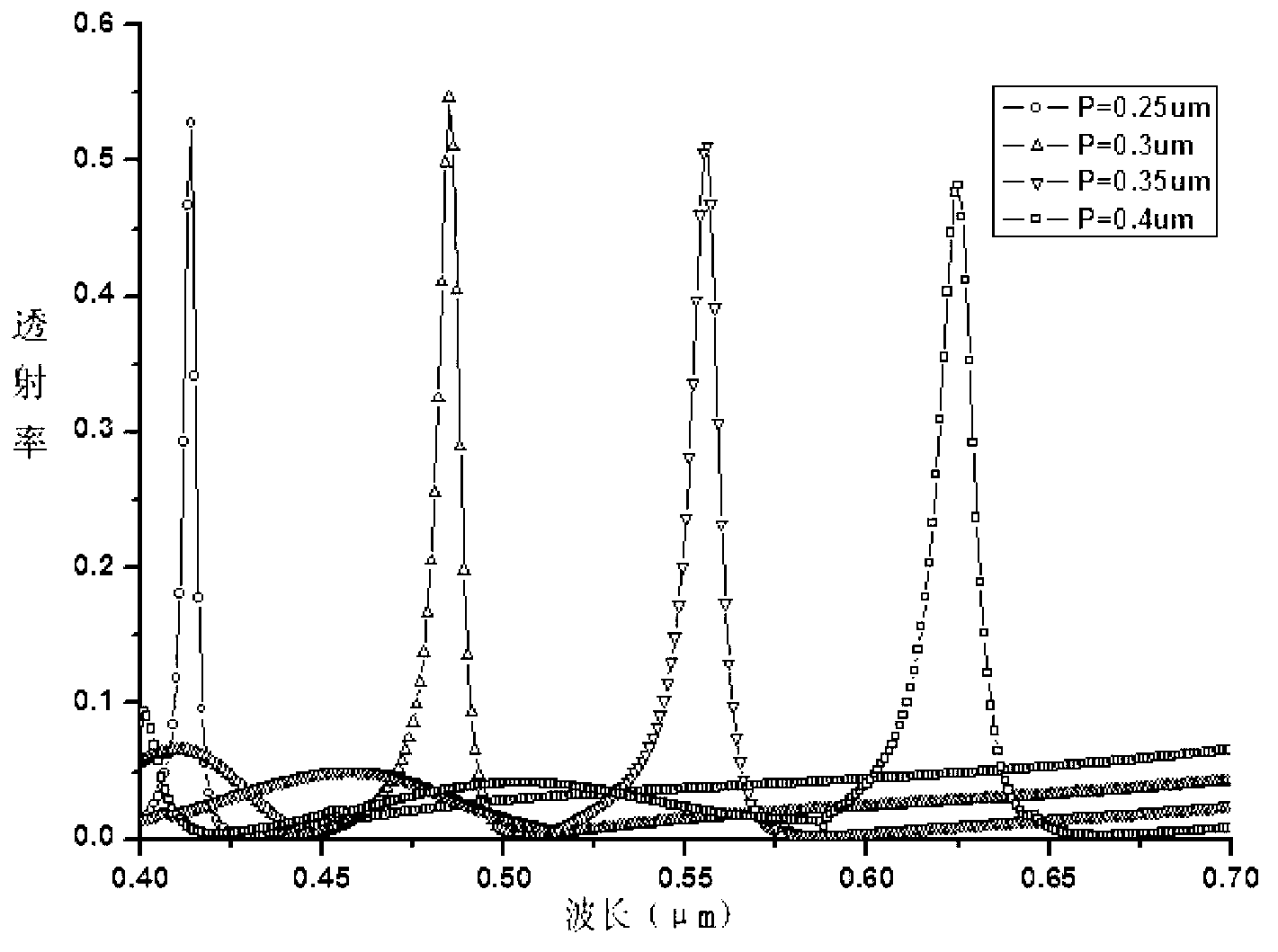

[0062] 1. Duty cycle

[0063] The duty cycle affects the transmittance at the peak transmittance wavelength, as shown in the attached Figure 5 shown. The figure shows that when the duty cycle f=0.7, the transmittance is as high as 85%, but at this time there will be another sub-peak near the peak wavelength, which is caused by the diffraction process of the two-dimensional metal grating, in order to avoid For the generation of this secondary peak, the duty ratio f=0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com