Manufacturing method for leading-out terminals of ceramic integrated circuit encapsulation casing and special lead framework

A technology of ceramic packaging and integrated circuits, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of limited rework times, unsatisfactory assembly and welding processes, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

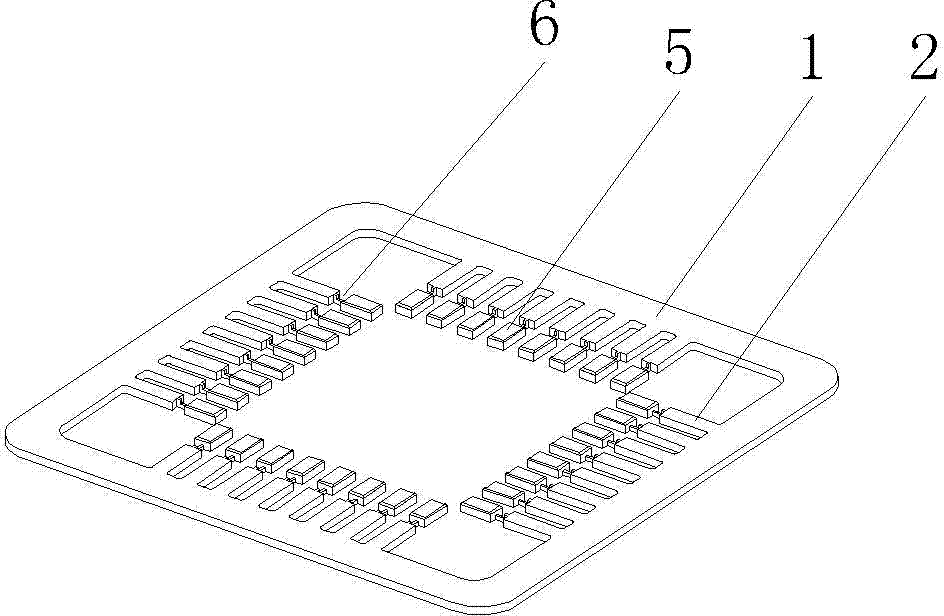

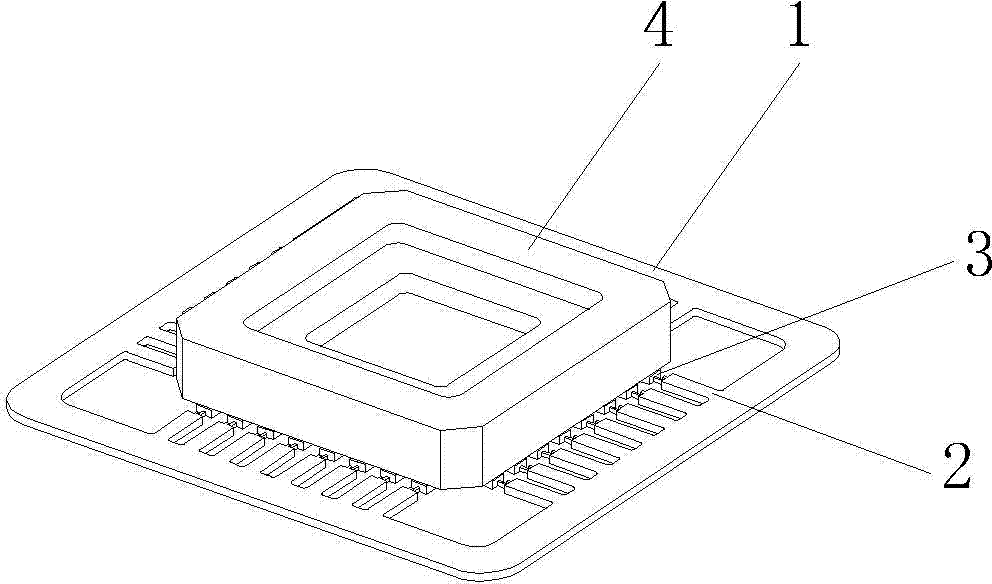

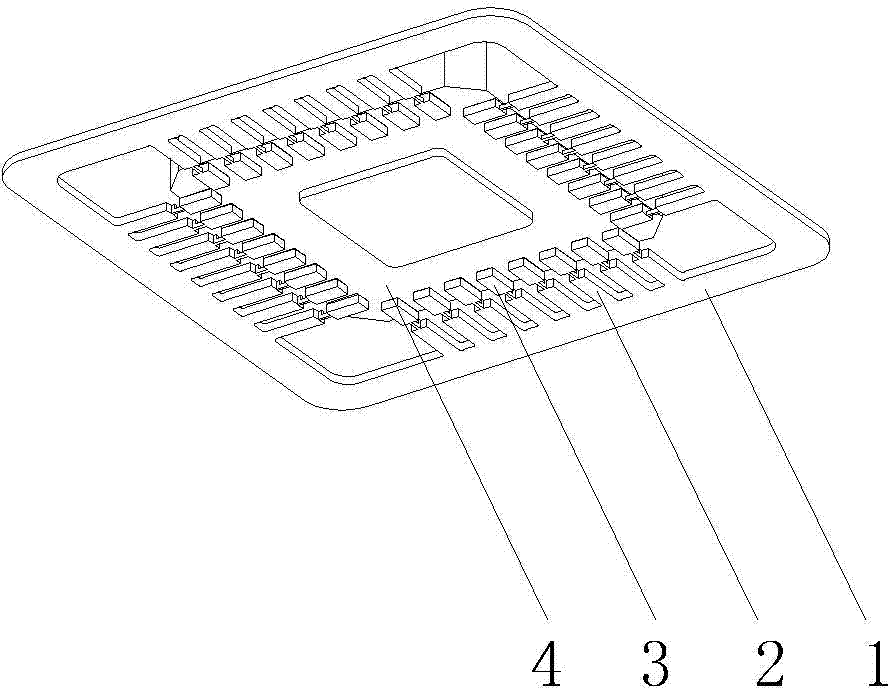

[0019] Figure 5 The first specific implementation of the special lead frame of the method for making the lead end of the integrated circuit ceramic package shell of the present invention is given. It includes the outer frame 1 and the lead 2 to form a grid bar structure with a frame. The lead 2 is Bars, the outer end of the lead 2 is connected to the outer frame 1, the number of the lead 2 is the same as the number of the pads on the ceramic shell 4, the spacing of the lead 2 is the same as that of the pads on the ceramic shell 4, and the inner end of the lead 2 There is a one-to-one correspondence with the pads on the ceramic shell 4 . The material used to make the lead frame can be iron-nickel alloy, kovar, copper sheet or iron-nickel alloy with solder, kovar, copper sheet, etc., and can also be 4J29, 4J42 and other metals. The thickness of the lead frame can be made of 0.1-0.5mm, preferably 0.15-0.25mm in thickness, and the method of making the lead frame can be punching,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com