Method for preparing graphene through carrying out ultrasonic stripping on graphite

A technology of exfoliating graphite and ultrasonic exfoliation, which is applied in the direction of graphene and nano-carbon, can solve problems such as introduction, graphene quality degradation, and failure to meet application requirements, and achieve low preparation costs, easy operation control, and industrialized mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

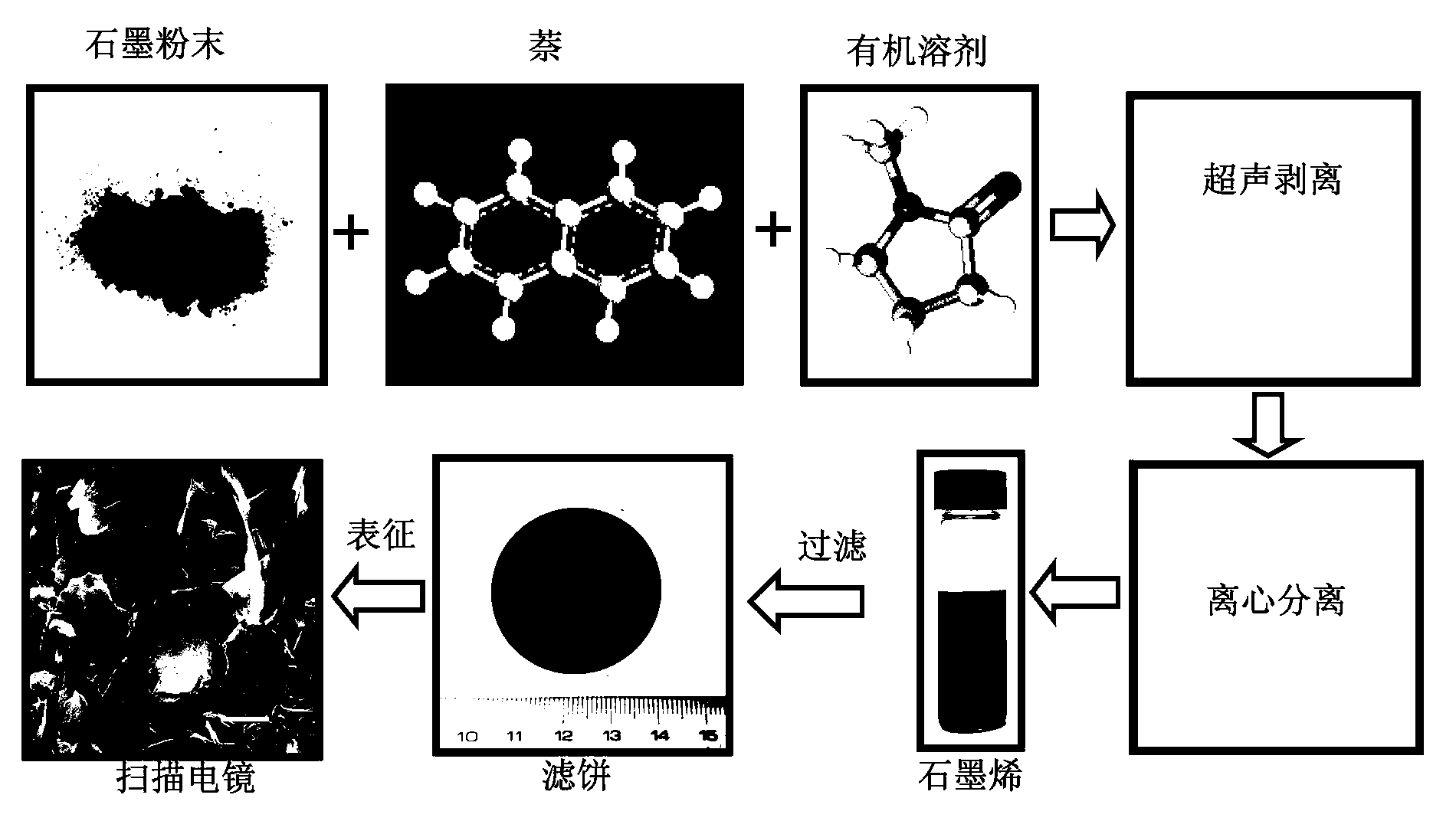

Method used

Image

Examples

Embodiment 1

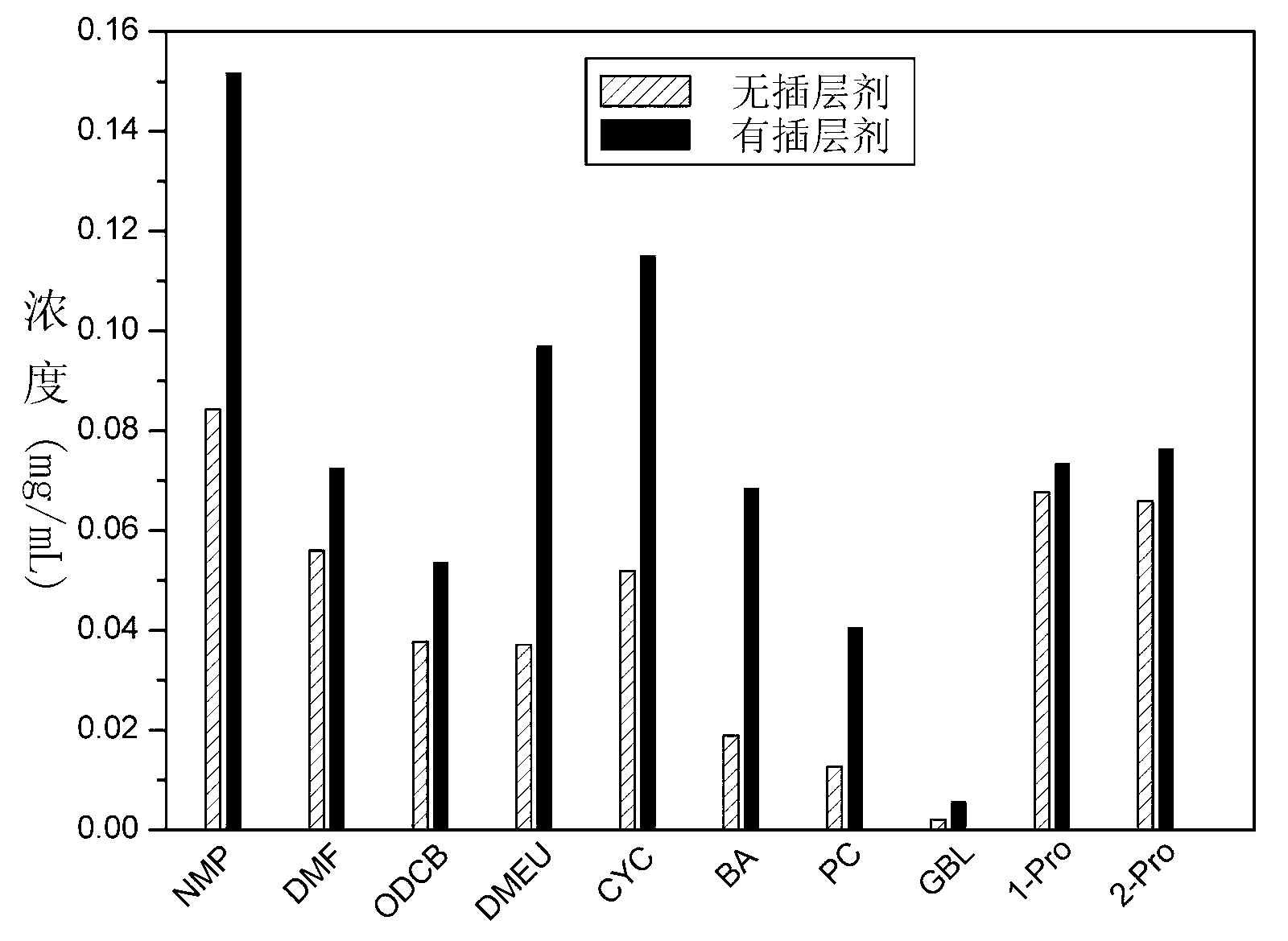

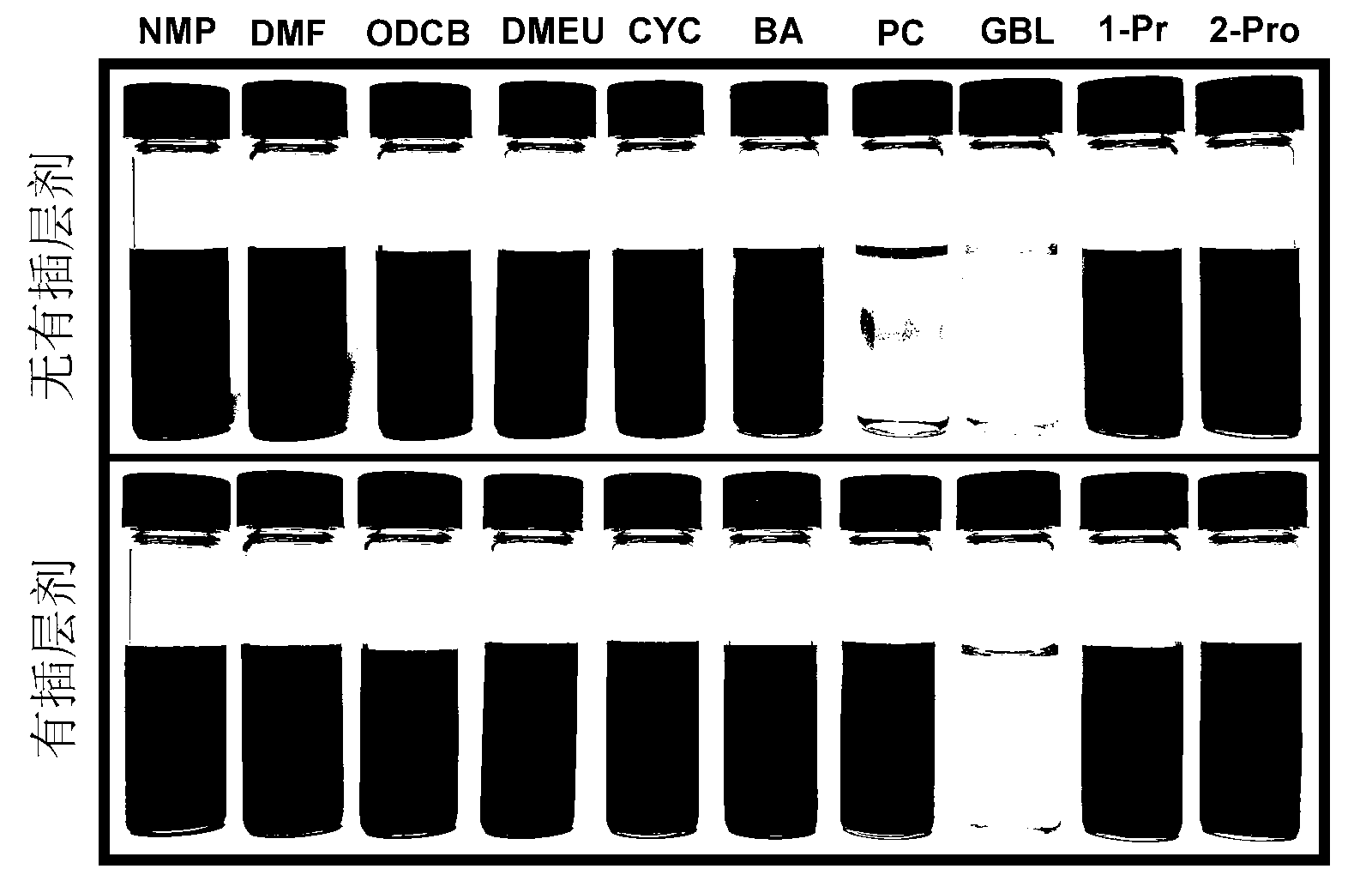

[0037] Graphite powder and intercalation agent were put into N-methylpyrrolidone (NMP) solvent according to the mass ratio of 1:0.5. The size of the graphite powder is 45 μm, and the concentration of the intercalation agent in the mixed solution is 2 mg / mL. The intercalant is naphthalene. The obtained mixed solution was subjected to an ultrasonic stripping reaction at 30° C., and the stripping reaction time was 90 minutes. The product obtained by the reaction is subjected to centrifugation, the centrifugation speed is 1000 RPM, and the centrifugation speed time is 30 minutes. After centrifugal separation, remove the supernatant, which is the graphene dispersion. The graphene dispersion is vacuum filtered, and the pore diameter of the filter membrane is 0.1 μm.

Embodiment 2

[0039]Put the graphite powder and the intercalation agent into the dimethylformamide (DMF) solvent according to the mass ratio of 1:0.2. The size of the graphite powder is 45 μm, and the concentration of the intercalation agent in the mixed solution is 2 mg / mL. The intercalating agent is phenanthrene. The obtained mixed solution was subjected to an ultrasonic stripping reaction at 30° C., and the stripping reaction time was 90 minutes. The product obtained by the reaction is subjected to centrifugation, the centrifugation speed is 1000 RPM, and the centrifugation speed time is 30 minutes. After centrifugal separation, remove the supernatant, which is the graphene dispersion. The graphene dispersion is vacuum filtered, and the pore diameter of the filter membrane is 0.1 μm.

Embodiment 3

[0041] Put the graphite powder and the intercalation agent into the 1,2-dichlorobenzene (ODCB) solvent according to the mass ratio of 1:1. The size of the graphite powder is 45 μm, and the concentration of the intercalation agent in the mixed solution is 2 mg / mL. The intercalating agent is phenanthrene. The obtained mixed solution was subjected to an ultrasonic stripping reaction at 30° C., and the stripping reaction time was 90 minutes. The product obtained by the reaction is subjected to centrifugation, the centrifugation speed is 1000 RPM, and the centrifugation speed time is 30 minutes. After centrifugal separation, remove the supernatant, which is the graphene dispersion. The graphene dispersion is vacuum filtered, and the pore diameter of the filter membrane is 0.22 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com