Production process of complex phosphate fertilizer

A production process and technology for mixing fertilizers, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problem of being susceptible to weather, electricity, water, and mechanical failures, heavy metal lead easily exceeding quality standards, and difficult to control moisture and free acid. and other issues, to achieve the effect of consolidating the sustainable development of agriculture, improving the quality and structure of soil, and promoting the sustainable development of industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

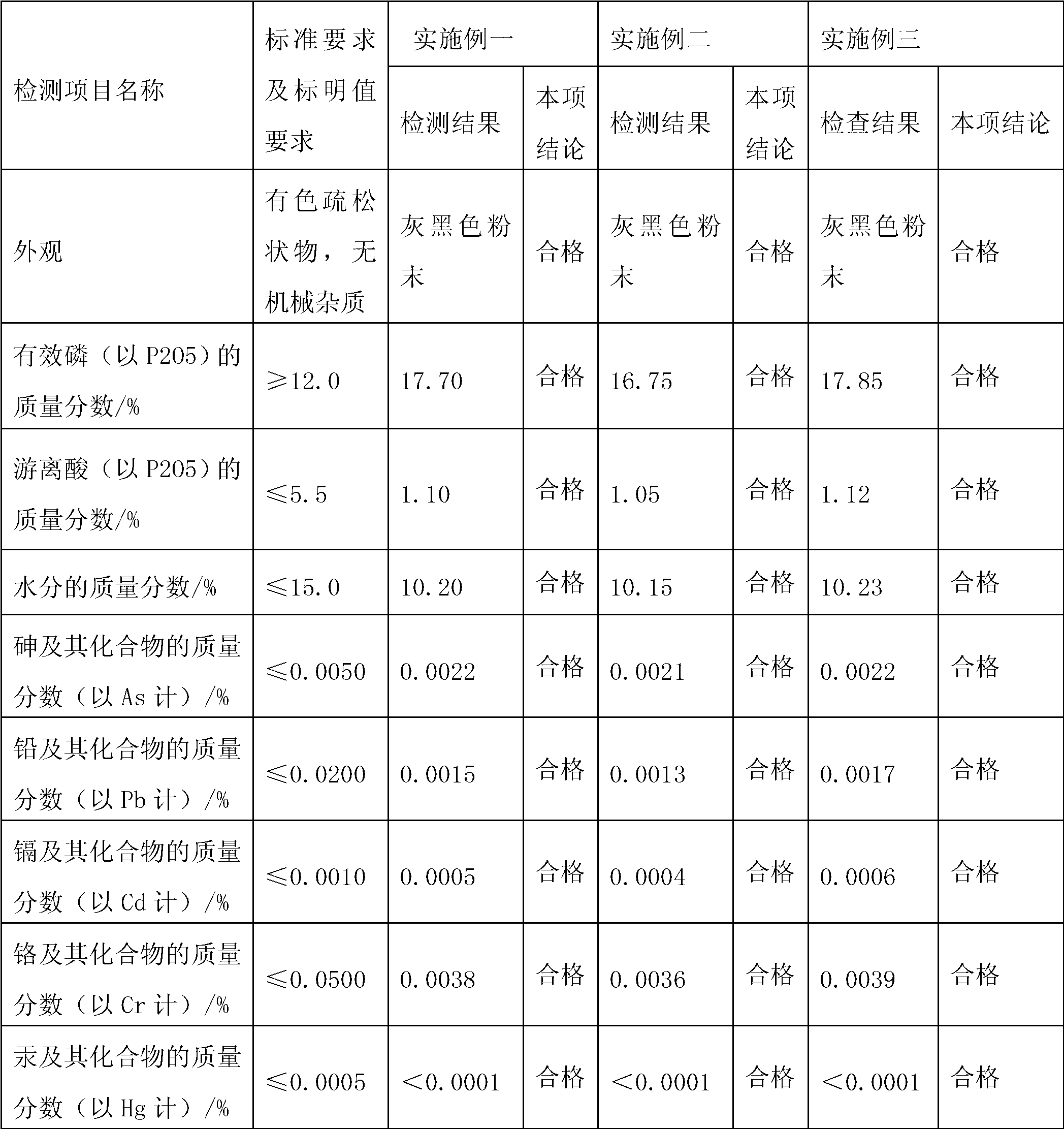

Embodiment 1

[0037] A kind of production technology of compound phosphate fertilizer, it comprises the following steps:

[0038] (1) Mix 14.8 tons of phosphorus-containing waste ash and 18.2 tons of superphosphate evenly to obtain 33 tons of mixed fertilizer A;

[0039] (2) Evenly mix 9 tons of phosphorus slag with 18 tons of filter acrylic to obtain 27 tons of mixed fertilizer B;

[0040] (3) Mix 33 tons of mixed fertilizer A with 27 tons of mixed fertilizer B to obtain 60 tons of mixed fertilizer C;

[0041] (4) Mix 60 tons of mixed fertilizer C and 240 tons of pot ash evenly to get 300 tons of mixed fertilizer D;

[0042] (5) Mix 300 tons of mixed fertilizer D and 600 tons of white fertilizer evenly to obtain 900 tons of finished product.

[0043] Wherein, the production of superphosphate is as follows:

[0044] Use phosphate rock with a content of ≥24% and add water to grind it into a water content of 28% to 33%, a fineness of 88 to 98 mesh, mix the pulp with 98% concentration of su...

Embodiment 2

[0047] A kind of production technology of compound phosphate fertilizer, it comprises the following steps:

[0048] (1) Evenly mix 12.5 tons of phosphorus-containing waste ash with 15.1 tons of superphosphate to obtain 27.6 tons of mixed fertilizer A;

[0049] (2) Evenly mix 11.9 tons of phosphorus slag with 21.8 tons of filter acrylic to obtain 33.7 tons of mixed fertilizer B;

[0050] (3) Mix 27.6 tons of mixed fertilizer A with 33.7 tons of mixed fertilizer B to obtain 61.3 tons of mixed fertilizer C;

[0051] (4) Evenly mix 61.3 tons of mixed fertilizer C with 200 tons of pot ash to obtain 261.3 tons of mixed fertilizer D;

[0052] (5) Mix 261.3 tons of mixed fertilizer D and 638.7 tons of white fertilizer evenly to obtain 900 tons of finished products.

[0053] Wherein, the production of superphosphate is as follows:

[0054] Grind 70 tons of phosphate rock with a content of 24% into a water ball to form a pulp with a water content of 30% and a fineness of 92 mesh, mix...

Embodiment 3

[0056] A kind of production technology of compound phosphate fertilizer, it comprises the following steps:

[0057] (1) Mix 16 tons of waste ash containing phosphorus and 13 tons of superphosphate evenly to obtain 29 tons of mixed fertilizer A;

[0058] (2) Mix 11 tons of phosphorus slag and 18 tons of filter acrylic evenly to obtain 29 tons of mixed fertilizer B;

[0059] (3) Mix 29 tons of mixed fertilizer A with 29 tons of mixed fertilizer B to obtain 58 tons of mixed fertilizer C;

[0060] (4) Mix 58 tons of mixed fertilizer C and 283.4 tons of pot ash evenly to obtain 341.4 tons of mixed fertilizer D;

[0061] (5) Mix 341.4 tons of mixed fertilizer D and 558.6 tons of white fertilizer evenly to obtain 900 tons of finished products.

[0062] Wherein, the production of superphosphate is as follows:

[0063] Grind 70 tons of phosphate rock with a content of 24% into a water ball to form a slurry with a water content of 33%, a fineness of 98 mesh, and 33 tons of sulfuric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com