A tire anti-aging agent

An anti-aging agent and anti-aging agent technology, which is applied in the field of mixed anti-aging agents, can solve the problems that anti-aging agents cannot achieve anti-aging effects, etc., and achieve the effects of high practical effect, good comprehensive effect, and convenient quantitative use and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

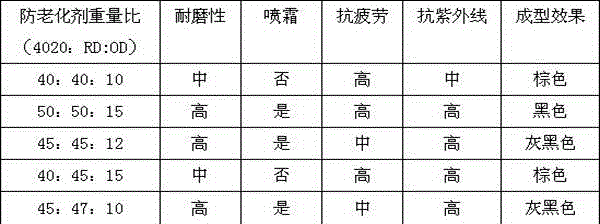

[0018] Example 1: A tire anti-aging agent, in parts by weight including the following components: anti-aging agent 402040-50 parts by weight, anti-aging agent RD40-50 parts by weight, anti-aging agent OD10-15 parts by weight, of which anti-aging agent 4020, anti-aging The weight ratio between RD and anti-aging agent OD is 4-5:4-5:1-1.5, and the weight ratio of different components in the anti-aging agent has various ratios, as shown in the following table , The ratio of practical effect is better: 40:45:15.

[0019]

[0020] The anti-aging agent 4020 of the present invention is N-(1,3-dimethylbutyl)-N-phenyl-p-phenylenediamine, and the anti-aging agent RD is 2,2,4-trimethyl -1,2-Dichlorinated quinoline polymer, the anti-aging agent OD is octylated diphenylamine. After the synergy between the anti-aging agents, the mixed product improves the overall wear resistance of the anti-aging agent. Resistance, fatigue resistance and UV resistance.

Embodiment 2

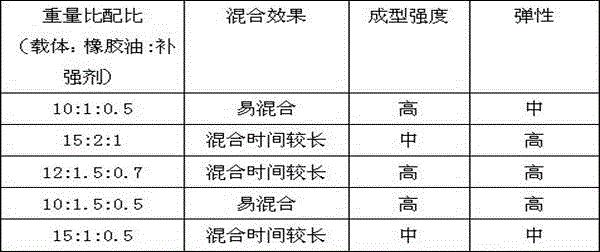

[0021] Example 2: The elastic carrier of the present invention is one or a mixture of natural rubber, styrene butadiene rubber, nitrile rubber, and chloroprene rubber. The preferred elastic carrier is 10-15 parts by weight, and the ductile carrier is used to assist in Kinds of antioxidants are mixed and adhered to form.

[0022] The dispersant of the present invention is one of stearic acid, liquid paraffin, and microcrystalline wax. The preferred dispersant is 2-3 parts by weight. The dispersant improves the dispersion effect of the elastic carrier and the anti-aging agent mixture, and mixes evenly .

[0023] The rubber oil of the present invention is used to improve the elasticity and ease of mixing of the elastic carrier, and is convenient to be mixed and molded with a low melting point antioxidant. The rubber reinforcing agent is used to increase the strength of the elastic carrier and increase the strength of the particles after molding. , The preferred rubber oil is 1-2 par...

Embodiment 3

[0025] Example 3: The preparation steps of the present invention are:

[0026] 1) Dissolve anti-aging agent 4020, anti-aging agent RD and anti-aging agent OD in acetone solution in sequence and mix thoroughly; filter to remove infusible impurities; low-melting anti-aging agent is not easy to use melt mixing, use the same solvent to mix, not mixing The effect is good, and it can also remove impurities in the antioxidant.

[0027] 2) Heat the elastic carrier to a molten state, and add dropwise the acetone solution in which the mixed ageing agent is dissolved while stirring; at the same time, add the dispersant and rubber oil sequentially.

[0028] 3) Stir for 2-3 hours, after the rubber reinforcing agent is fully stirred evenly, add the rubber reinforcing agent and cool to room temperature.

[0029] 4) The cooled mixture is stirred by a jet mill to obtain mixed fixed anti-aging agent particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com