Aureobasidium Pullulan producing pullulan with high yield by utilizing xylose and application of Aureobasidium Pullulan

A technology of Aureobasidium pullulans and pullulan, which is applied in the direction of microorganism-based methods, microorganisms, fungi, etc., can solve the problems of complex process and high cost, and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

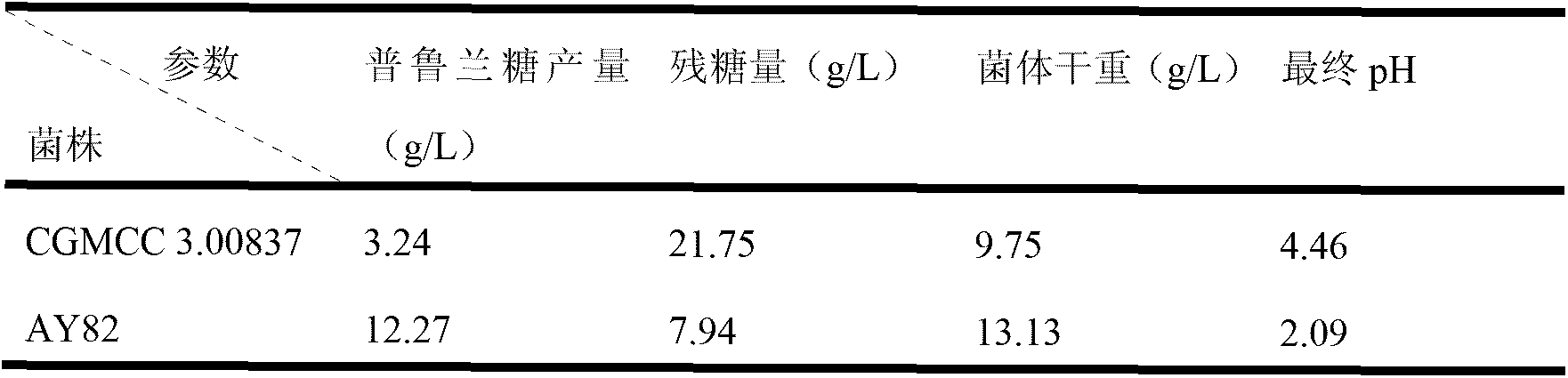

[0025] Example 1: Screening of mutant strains of Aureobasidium pullulans with high yield of pullulan using xylose

[0026] Take Aureobasidium pullulan (Aureobasidium Pullulan) CGMCC3.00837 as the starting strain, select the ultraviolet mutagenic dose (irradiation 5min) with a lethality rate of 82.4% to carry out mutagenesis to Aureobasidium pullulan, dilute the bacterium solution after the mutation and evenly Spread on a high-concentration xylose plate (xylose concentration 100g / L), culture at 30°C in the dark for 4-5 days, and then pick mutants. The mutant strains were re-screened in the shake flask fermentation experiment, and the amount of pullulan sugar produced was measured after 168 hours of fermentation. Compared with the original strain, a mutant strain AY82 that utilizes xylose to produce pullulan sugar was obtained, and the pullulan sugar yield was relatively high. The starting strain has been greatly improved, and the fermentation results are shown in Table 1.

[0...

Embodiment 2

[0029] Embodiment 2: Shake flask fermentation of xylose medium

[0030] Taking the mutant strain AY82 as the experimental strain, using xylose as the carbon source, and optimizing the medium and fermentation conditions, the optimized xylose fermentation medium is: xylose 50g / L, (NH 4 ) 2 SO 4 1.2g / L, K 2 HPO 4 6g / L, MgSO 4 ·7H 2 O0.4g / L, NaCl2g / L, yeast extract powder 1.0g / L, sterilized by high pressure steam at 121°C for 20min; the optimized fermentation conditions are: inoculum size 8%, shaker speed 200r / min, temperature 28°C, initial pH The value is 6.5, and the culture time is 168h.

[0031] Pick a loop of AY82 bacteria from the activated slope and inoculate it into a 250mL Erlenmeyer flask containing 50mL of seed medium for cultivation, and cultivate it on a shaker at 28°C and 200r / min for 24-48h to obtain a seed solution. The composition of the seed medium is: xylose 20g / L, (NH 4 ) 2 SO 4 1.0g / L, K 2 HPO 4 4g / L, MgSO 4 ·7H 2 O0.2g / L, NaCl4g / L, yeast extract...

Embodiment 3

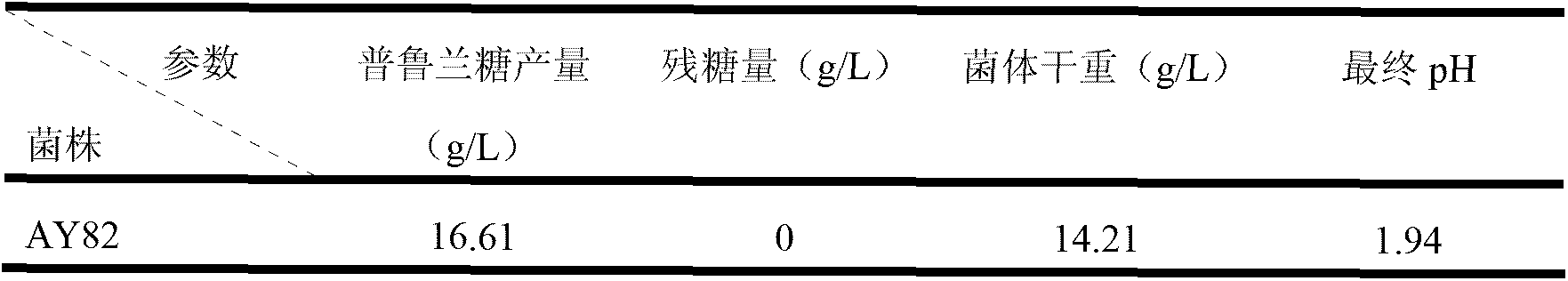

[0035] Embodiment 3: Shake flask fermentation of xylose mother liquor culture medium

[0036] The preparation of the seed liquid and the shake flask fermentation conditions were basically the same as in Example 2.

[0037] The components of the fermentation medium are: xylose mother liquor (xylose 35-40%, arabinose 8-16%, galactose 9-15%, glucose 8-11%) diluted to a total sugar content of 50g / L in the medium , (NH 4 ) 2 SO 4 1.2g / L, K 2 HPO 4 6g / L, MgSO 4 ·7H 2 O0.4g / L, NaCl2g / L, yeast extract powder 1.0g / L, initial pH6.5. Sterilized by high pressure steam at 121°C for 20min. The fermentation results are shown in Table 3.

[0038] Table 3 AY82 xylose mother liquor medium fermentation result

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com