Primary side single-phase bridge-subsidiary side three-phase bridge high frequency chain inverter and digital control system thereof and method thereof

A single-phase bridge and high-frequency link technology, applied in the field of power electronic converters and their control, can solve the problems of large switch tube voltage spikes, complex circuit structures, and limited processing power, and achieve heat dissipation, volume reduction, and power generation reduction. heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with specific embodiment, further illustrate the present invention, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various equivalent forms of the present invention All modifications fall within the scope defined by the appended claims of the present application.

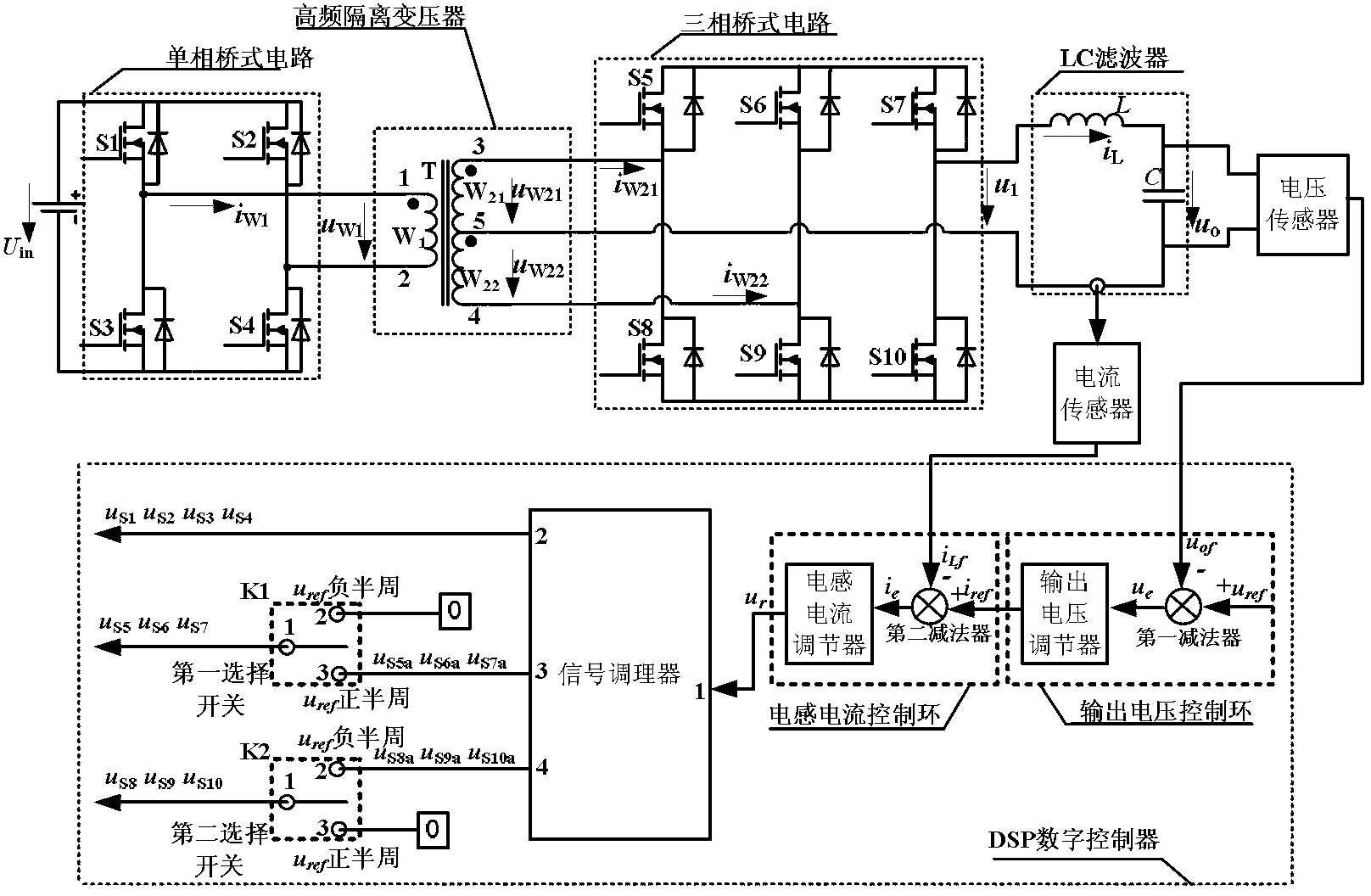

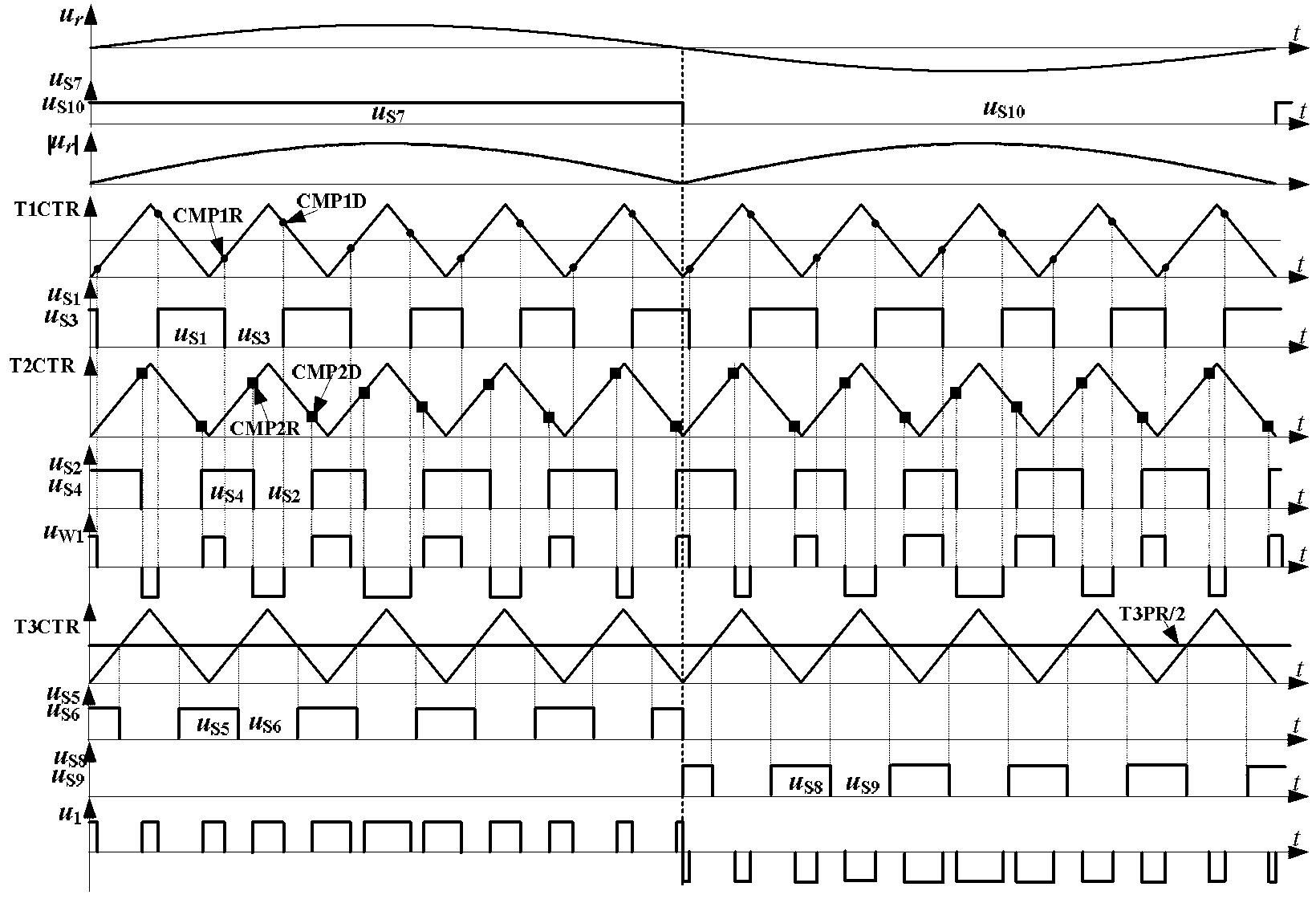

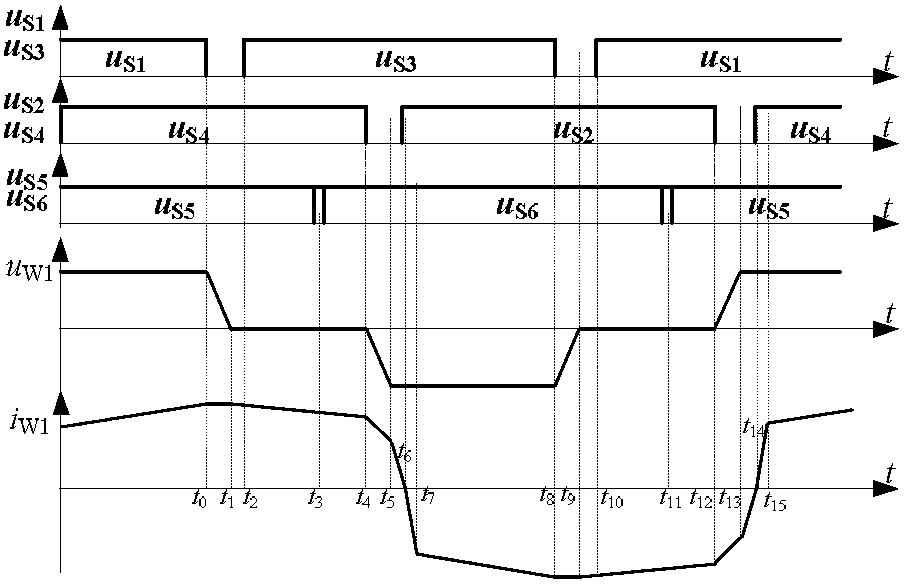

[0044] Such as figure 1 As shown, the primary side single-phase bridge-secondary side three-phase bridge high-frequency link inverter includes the input voltage U in , Single-phase bridge circuit, high-frequency isolation transformer T, three-phase bridge circuit and LC filter, the following will describe in detail their interconnection and components.

[0045] The single-phase bridge circuit adopts the phase-shift control method, including switch tubes S1-S4 with anti-parallel diodes, where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com