Water-soluble lutein ester, preparation method thereof and hard candy containing same

A technology of water-soluble lutein and lutein ester, which is applied in the field of emulsification modification of oil-soluble lutein ester and hard candy of water-soluble lutein ester, which can solve the problem of limited application and insoluble lutein ester Water and other problems, to achieve the effect of good emulsification, good water solubility, and suitable taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

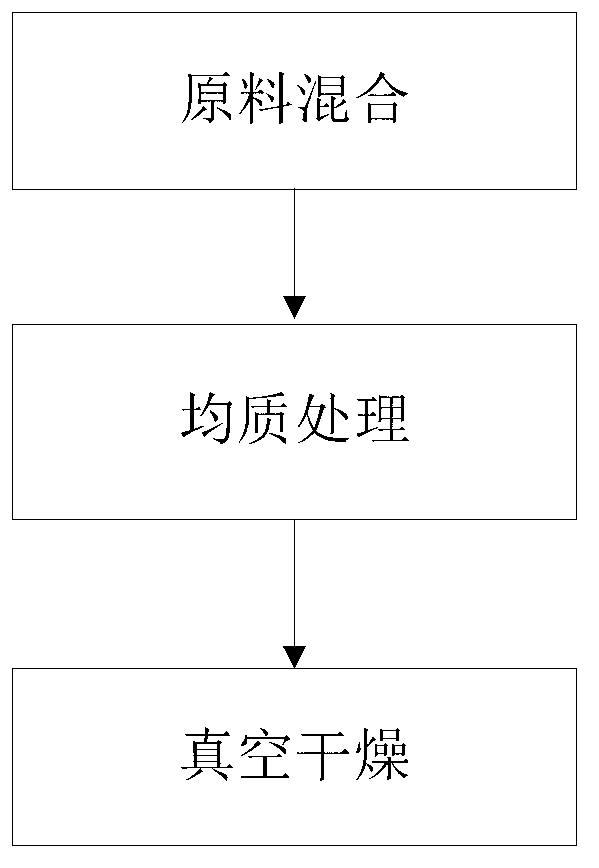

[0037] Preparation process of water-soluble lutein ester:

[0038] Heat the oil-soluble lutein ester to 65°C, then add polyglycerol fatty acid ester and tert-butyl hydroquinone, and place the mixture in a mixer at a speed of 200 rpm for 2 hours to make the mixture Mix well. Based on the weight of the oil-soluble lutein ester, the amount of polyglycerin fatty acid ester is 2%, and the amount of tert-butyl hydroquinone is 0.5%. Use a high-speed shear homogenizer to homogenize the mixed mixture at a speed of 2500 rpm for 35 minutes to obtain a lutein ester emulsion, which is vacuum-dried at 55° C., pulverized, and passed through a 100-mesh sieve. Water-soluble lutein ester powder is obtained.

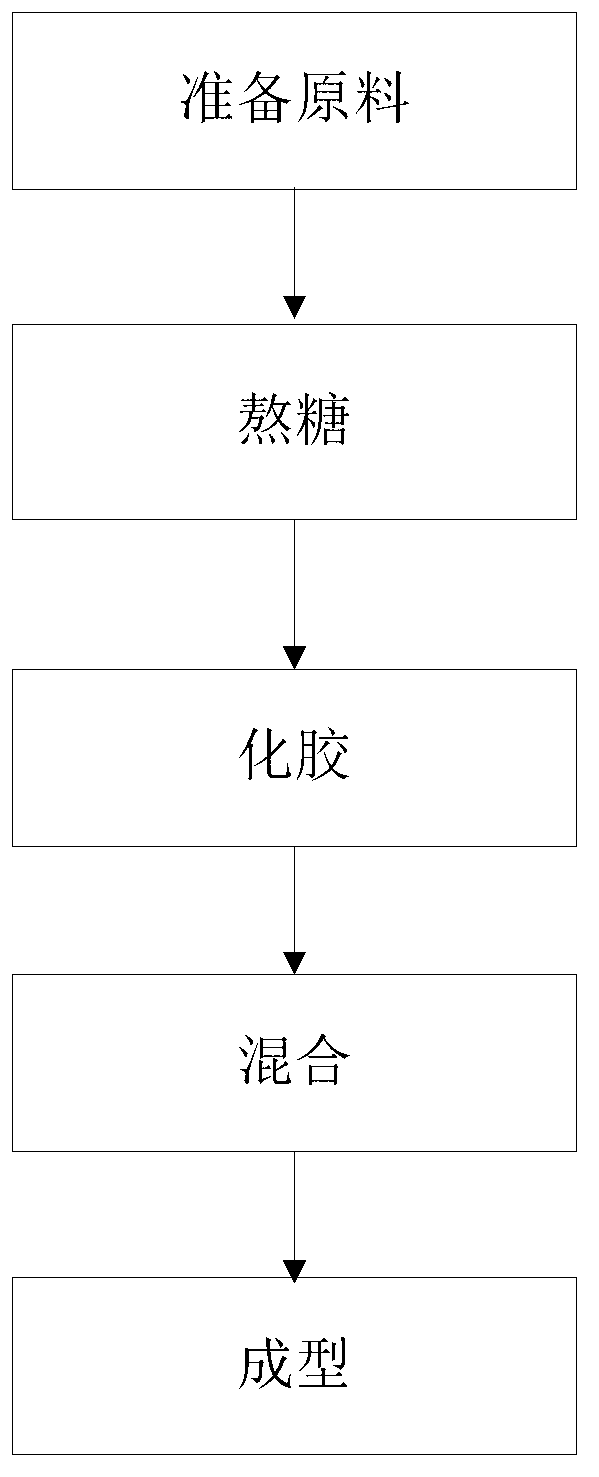

[0039] The process of preparing hard candy using the water-soluble lutein ester obtained above:

[0040] Prepare the following raw materials in terms of mass percentage: 75% of sugar substances, 0.1% of water-soluble lutein ester powder, 2% of apple juice concentrate, 1% of gelling agen...

Embodiment 2

[0043] Preparation process of water-soluble lutein ester:

[0044] Heat the oil-soluble lutein ester to 45°C, then add triglyceryl monostearate, polyglyceryl ricinoleate, butylhydroxyanisole and dibutylhydroxytoluene to it, and place the mixture in a blender Thoroughly stir at 300 rpm for 3 hours to fully mix the mixture. Based on the weight of oil-soluble lutein esters, the total amount of both the tripolyglycerol monostearate and the polyglycerol ricinoleate is 5%, and the butyl hydroxyanisole and dibutyl hydroxytoluene The total dosage is 0.3%. Use a high-speed shear homogenizer to homogenize the mixed mixture at a speed of 3500 rpm for 20 minutes to obtain a lutein ester emulsion, which is vacuum-dried at 55° C., pulverized, and passed through a 100-mesh sieve. Water-soluble lutein ester powder is obtained.

[0045] The process of preparing hard candy using the water-soluble lutein ester obtained above:

[0046] Prepare the following raw materials in terms of mass perc...

Embodiment 3

[0049] Preparation process of water-soluble lutein ester:

[0050] Heat the oil-soluble lutein ester to 50°C, then add diacetyl tartrate mono-diglyceride, polyethylene glycol 300, polyethylene glycol 400, propyl gallate and vitamin E, and place the mixture in a blender Stir well at 400 rpm for 1.5 hours to fully mix the mixture. Based on the weight of oil-soluble lutein esters, the total amount of the three diacetyl tartrate mono-diglycerides, polyethylene glycol 300 and polyethylene glycol 400 is 8%, and the propyl gallate and vitamin E The total dosage is 0.8%. Use a high-speed shear homogenizer to homogenize the mixed mixture at a speed of 3000 rpm for 25 minutes to obtain a lutein ester emulsion, which is vacuum-dried at 55°C and then pulverized, passed through a 100-mesh sieve, Water-soluble lutein ester powder is obtained.

[0051] The process of preparing hard candy using the water-soluble lutein ester obtained above:

[0052] Prepare the following raw materials in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com