Method for producing feed-grade manganese sulfate monohydrate

A technology of water sulfuric acid and feed grade, applied in the direction of manganese sulfate, solution crystallization, etc., can solve the problems of high impurity content of manganese sulfate, easy moisture absorption and agglomeration, poor fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

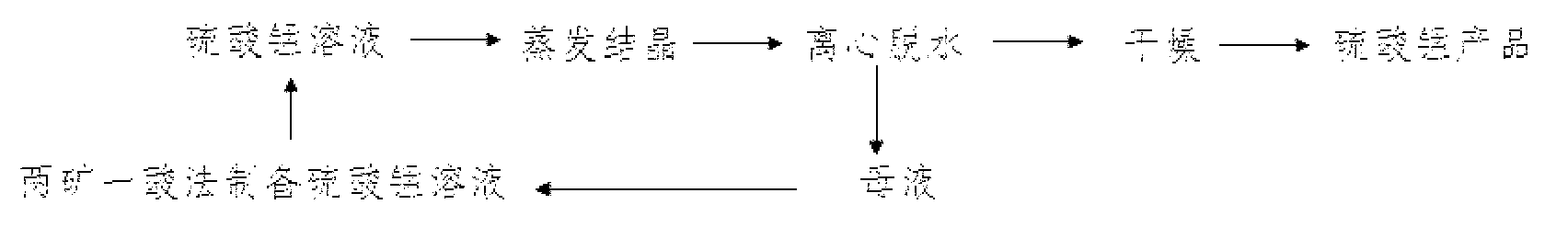

Image

Examples

Embodiment 1

[0035] Embodiment 1 adopts the inventive method to produce feed grade manganese sulfate monohydrate

[0036] a. Manganese sulfate prepared by two mines and one acid method: 1000kg of manganese dioxide ore (manganese content is 16%, magnesium content is 0.35%), pyrite (sulfur content is 39%, iron content is 35%) 10kg, with 98 % sulfuric acid solution leaching, obtain manganese sulfate solution;

[0037] b. Evaporation and crystallization of manganese sulfate solution. The temperature of evaporation and crystallization is 100°C. Evaporate until the solution has a solid content of 50%, and then separate the solid and liquid; the solid obtained from separation is dried with air flow to obtain the product of manganese sulfate monohydrate; the filtrate obtained from separation is mother liquor 1 ;

[0038] c. Add manganese dioxide ore slurry to mother liquor 1 to remove, filter, remove iron impurities, and then evaporate and crystallize. The temperature of evaporation and crystalli...

Embodiment 2

[0046] Embodiment 2 adopts the inventive method to produce feed grade manganese sulfate monohydrate

[0047] a. Manganese sulfate prepared by two mines and one acid method: 1000kg of manganese dioxide ore (manganese content is 16%, magnesium content is 0.35%), pyrite (sulfur content is 39%, iron content is 35%) 10kg, with 98 % sulfuric acid solution leaching, obtain manganese sulfate solution;

[0048] b. Evaporation and crystallization of manganese sulfate solution. The temperature of evaporative crystallization is 80°C. Evaporate until the solution has a solid content of 55%, and then separate the solid and liquid; dry the solid obtained by airflow to obtain the product of manganese sulfate monohydrate; the filtrate obtained by separation is the mother liquor 1 ;

[0049] c. Add manganese dioxide ore slurry to mother liquor 1 to remove, filter, remove iron impurities, and then evaporate and crystallize. The temperature of evaporation and crystallization is 90°C. Evaporate u...

Embodiment 3

[0057] Embodiment 3 adopts the inventive method to produce feed grade manganese sulfate monohydrate

[0058] a. Manganese sulfate prepared by two mines and one acid method: 1000kg of manganese dioxide ore (manganese content is 16%, magnesium content is 0.35%), pyrite (sulfur content is 39%, iron content is 35%) 10kg, with 98 % sulfuric acid solution leaching, obtain manganese sulfate solution;

[0059] b. Evaporation and crystallization of manganese sulfate solution. The temperature of evaporative crystallization is 110°C. Evaporate until the solution has a solid content of 45%, and then separate the solid from the liquid; dry the separated solid with airflow to obtain the product of manganese sulfate monohydrate; the filtrate obtained from the separation is the mother liquor 1 ;

[0060] c. Add manganese dioxide ore slurry to mother liquor 1 to remove, filter, remove iron impurities, and then evaporate and crystallize. The temperature of evaporation and crystallization is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com