Method for preparing cyclohexanone serving as raw material of caprolactam from cyclohexene-hydration cyclohexanol

A technology for caprolactam and cyclohexanol, which is applied in the field of cyclohexanone, a raw material for preparing caprolactam from cyclohexanol by a hydration cyclohexene method, can solve the problems of high content of harmful impurities, difficulty in producing high-quality caprolactam, insufficient use methods, etc., and achieve side reactions. The effect of reducing energy consumption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

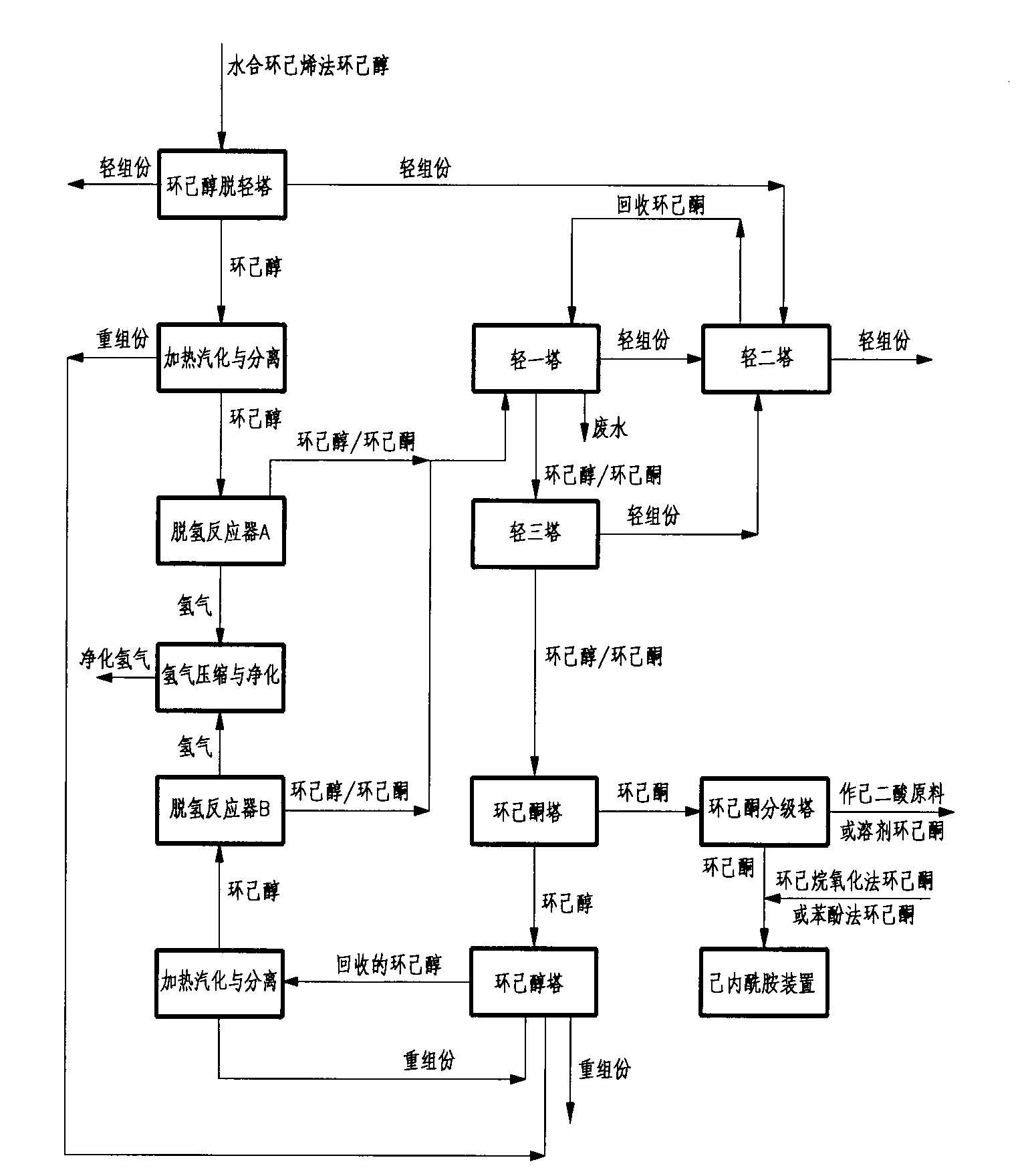

[0052] see image 3, the hydration cyclohexene method cyclohexanol enters the cyclohexanol light component removal tower, when the methyl cyclopentanol content in the hydration cyclohexene method cyclohexanol is greater than 50ppm, the cyclohexanol light component removal tower adopts the Distillation tower; when the content of methylcyclopentanols in the hydration cyclohexene method cyclohexanol is less than 50ppm, the cyclohexanol light component removal tower adopts a flash tower (device). Most of the light component impurities such as 2-methylcyclopentanol and 3-methylcyclopentanol are separated from the top of the tower, and are discharged from the system after condensation, and the remaining gas goes to the light second tower.

[0053] The bottom liquid of the cyclohexanol removal light component tower is heated and vaporized by the vaporizer, and the heavy component that is not vaporized during the heating and vaporization process of cyclohexanol is sent to the cyclohex...

Embodiment 2

[0071] see Figure 4 and Figure 5 The cyclohexanone obtained by hydrogenation and dehydrogenation of qualified cyclohexane oxidation method cyclohexanone or phenol is added to the conventional method of hydration cyclohexene method cyclohexanone. The mixing ratio of the hydration cyclohexene method cyclohexanone of the conventional method and the qualified cyclohexane oxidation method cyclohexanone is usually less than 1:3, when the total alkyl chain ketone content and the alkyl chain ketone content in the mixed cyclohexanone are less than 50ppm , the quality of mixed cyclohexanone meets the requirements, and can be used to produce high-quality caprolactam. During specific implementation, the mixing ratio needs to be calculated and determined by analyzing the content of harmful impurities in two kinds of cyclohexanone; the mixing ratio of the hydration cyclohexene method cyclohexanone of the conventional method and the qualified phenol method cyclohexanone is usually less th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com