Grid framework filler wall

A technology for filling walls and skeletons, applied to walls, building components, buildings, etc., can solve the problems of low strength of filling walls, high cost of main structure, complicated construction technology, etc., and achieve fast wall formation, low overall cost, and on-site construction The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

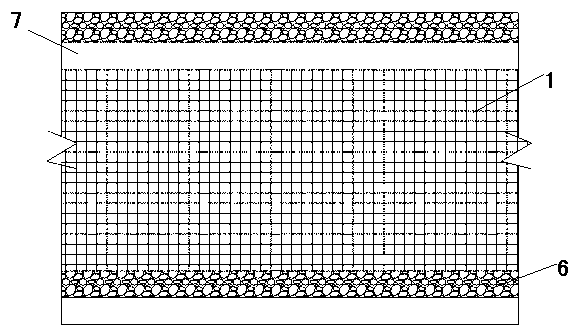

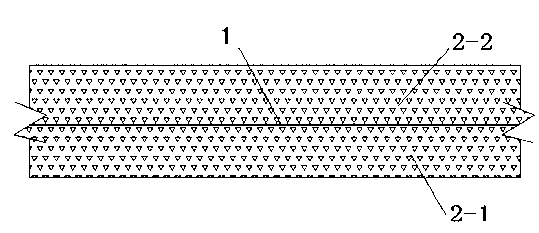

[0022] Such as figure 1 , 3 As shown, the grid frame 1 is made of glass fiber mesh roll material (vertical length 2900mm, mesh diameter 3mm), which is transported to the construction site after being produced in the factory, and the upper and lower ends of the grid frame 1 are fixed on the On the floor 6 and the beam 7, and in the plane of the central axis of the filling wall. Use two spraying machines to spray phosphogypsum slurry (gypsum mortar with phosphogypsum as the cementitious material) on the surface of the glass fiber mesh and wrap it on the surface quickly, and then spray 20mm thick on the two sides as the inner side Layer 2-1 and outer side layer 2-2. After 6 minutes, the phosphogypsum slurry solidifies and adheres to the grid skeleton 1 and has a certain strength and bearing capacity. It can be smoothed when the thickness reaches 90mm. This example is a 90mm solid wall, which can be used for general interior partition walls.

Embodiment 2

[0024] Such as figure 1 , 3 As shown, the grid frame 1 is made of metal mesh coiled material (vertical length 2900mm, mesh diameter 3mm), which is delivered to the construction site after being produced in the factory, and the upper and lower ends of the grid frame 1 are fixed to the floor with metal beading and expansion bolts 6 and beam 7, and in the plane of the central axis of the filling wall. Two spraying machines are used to spray phosphogypsum slurry (gypsum mortar with phosphogypsum as the cementitious material) on the surface of the metal mesh wire and quickly set and wrap it on the surface, and then two spraying machines are used to spray the desulfurized gypsum slurry ( The gypsum mortar with desulfurized gypsum as the cementitious material) is sprayed on the two sides of the metal mesh with a thickness of 20 mm each as the inner layer 2-1 and the outer layer 2-2. After 5 minutes, the desulfurized gypsum slurry solidifies and adheres to the grid On the skeleton 1...

Embodiment 3

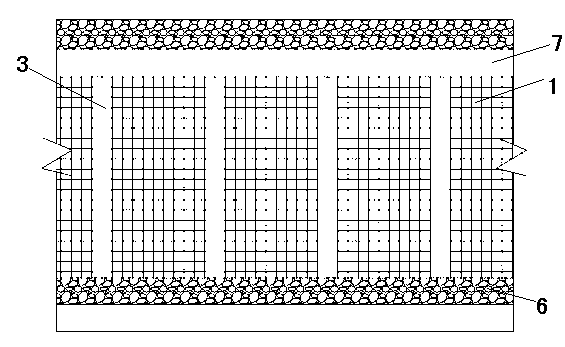

[0026] Such as figure 2 , 4 As shown, the grid frame 1 is made of glass fiber mesh roll material (vertical length 2900mm, mesh diameter 3mm), which is delivered to the construction site after being produced in the factory, and the upper and lower ends of the grid frame 1 are fixed on the On the floor 6 and the beam 7, and in the plane of the central axis of the filling wall, two spraying machines are used to spray the phosphogypsum slurry on the two surfaces of the glass fiber mesh with a thickness of 20mm and a width of 200mm, with two spraying machines at intervals of 900mm in the transverse direction. After 6 minutes, the phosphogypsum slurry is solidified and attached to the grid skeleton 1 to form a column 3 with a certain strength and bearing capacity. Then, the phosphogypsum slurry is sprayed on the surface of the grid skeleton 1 and the column 3 by a spraying machine to make the total thickness It can be smoothed when it reaches 90mm. This example is a 90mm solid wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com