An anti-corrosion, high temperature and wear-resistant cast pipe

A technology for high-temperature resistant and wear-resistant pipelines, which is applied in anti-corrosion coatings, pipeline anti-corrosion/rust protection, pipes, etc. Anti-friction function, high hardness, and strong resistance to organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

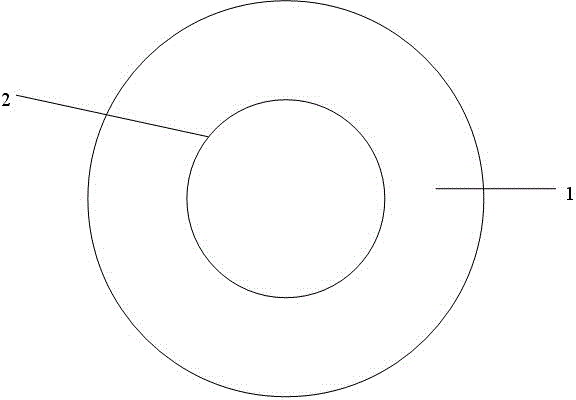

Image

Examples

Embodiment 1

[0059] A) Preparation of wear-resistant pipe body

[0060] 1) To obtain materials, select raw materials with the following chemical composition weight percentages:

[0061] C: 1.6%, V: 4.5%,

[0062] W: 9.1%, Mo: 7.6%,

[0063] Cr: 3.8%, Re: 0.15%,

[0064] Mn: 0.7%, Si: 0.05%,

[0065] B: 0.02%, Al: 0.2%,

[0066] Nb: 0.08%, Ni: 0.1%,

[0067] The balance is Fe and trace unavoidable impurities;

[0068] 2) Mix and heat ordinary steel scrap, ferro-niobium, ferronickel, ferro-tungsten, ferro-molybdenum, ferro-chromium and ferro-manganese, add carbon with pig iron or graphite, mix and heat to melt into molten steel, and add ferrosilicon for pre-deoxidation after the molten steel is melted ;

[0069] 3) According to the distribution ratio of raw materials, adjust the composition in front of the furnace and raise the temperature to 1580°C, then add aluminum blocks for final deoxidation, and then leave the furnace;

[0070] 4) Put the rare earth ferrosilicon alloy, ferrobor...

Embodiment 2

[0092] A) Preparation of wear-resistant pipe body

[0093] 1) To obtain materials, select raw materials with the following chemical composition weight percentages:

[0094] C: 2.7%, V: 6.0%,

[0095] W: 6.9%, Mo: 5.3%,

[0096] Cr: 5.4%, Re: 0.23%,

[0097] Mn: 0.6%, Si: 0.08%,

[0098] B: 0.01%, Al: 0.5%,

[0099] Nb: 1.1%, Ni: 0.2%,

[0100] The balance is Fe and trace unavoidable impurities;

[0101] 2) Mix and heat ordinary steel scrap, ferro-niobium, ferronickel, ferro-tungsten, ferro-molybdenum, ferro-chromium and ferro-manganese, add carbon with pig iron or graphite, mix and heat to melt into molten steel, and add ferrosilicon for pre-deoxidation after the molten steel is melted ;

[0102] 3) According to the distribution ratio of raw materials, adjust the composition in front of the furnace and raise the temperature to 1600°C, then add aluminum blocks for final deoxidation, and then leave the furnace;

[0103] 4) Put the rare earth ferrosilicon alloy, ferroboron,...

Embodiment 3

[0125] A) Preparation of wear-resistant pipe body

[0126] 1) To obtain materials, select raw materials with the following chemical composition weight percentages:

[0127] C: 3.7%, V: 8.5%,

[0128] W: 3.2%, Mo: 2.4%,

[0129] Cr: 8.9%, Re: 0.4%,

[0130] Mn: 0.3%, Si: 1.0%,

[0131] B: 0.01%, Al: 0.8%,

[0132] Nb: 2.4%, Ni: 0.3%,

[0133] The balance is Fe and trace unavoidable impurities;

[0134] 2) Mix and heat ordinary steel scrap, ferro-niobium, ferronickel, ferro-tungsten, ferro-molybdenum, ferro-chromium and ferro-manganese, add carbon with pig iron or graphite, mix and heat to melt into molten steel, and add ferrosilicon for pre-deoxidation after the molten steel is melted ;

[0135] 3) According to the distribution ratio of raw materials, adjust the composition in front of the furnace and raise the temperature to 1630°C, then add aluminum blocks for final deoxidation, and then leave the furnace;

[0136] 4) Put the rare earth ferrosilicon alloy, ferroboron,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com