Ammonia power or refrigerating composite circulating system with adjustable output cold power ratio

A cycle system and power technology, applied in the field of ammonia power/refrigeration composite cycle system, can solve the problems of poor output cooling power ratio adjustment ability, and achieve the effects of reducing energy consumption, reducing heat consumption and improving refrigeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

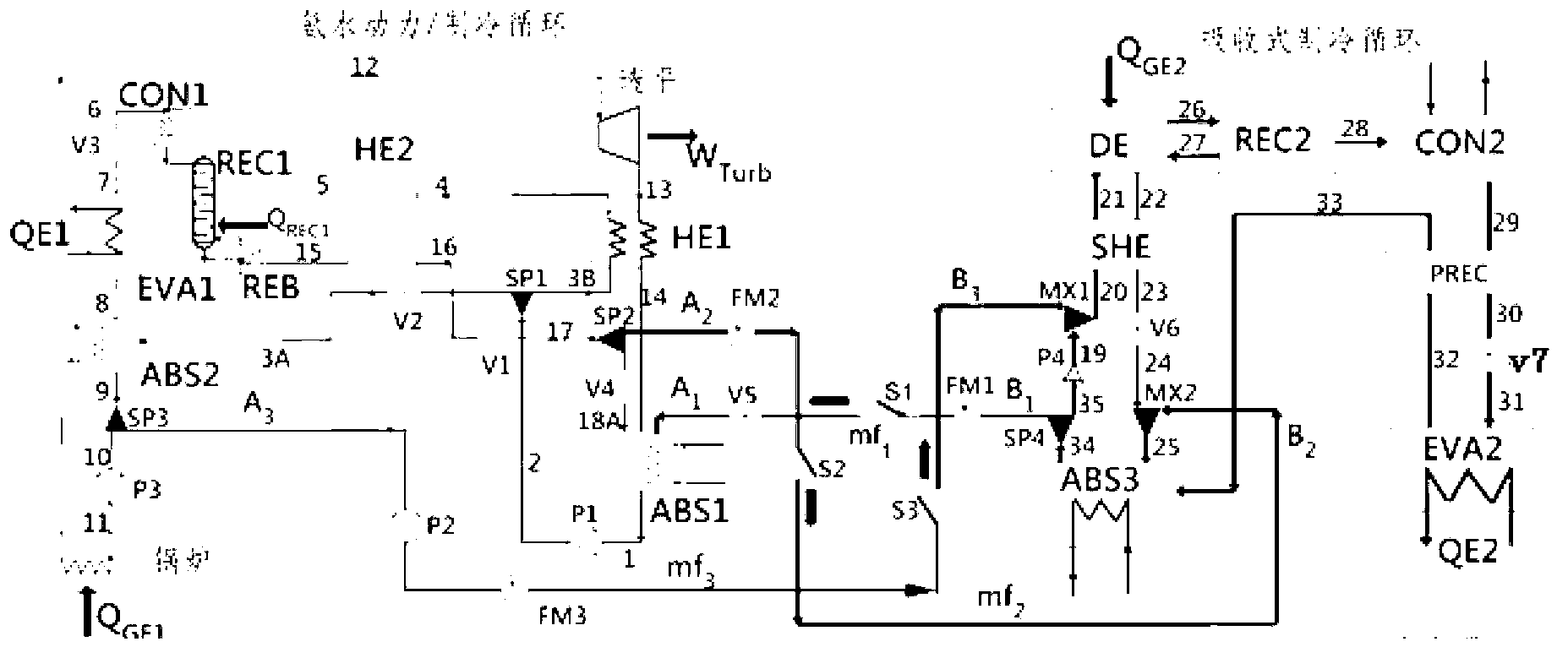

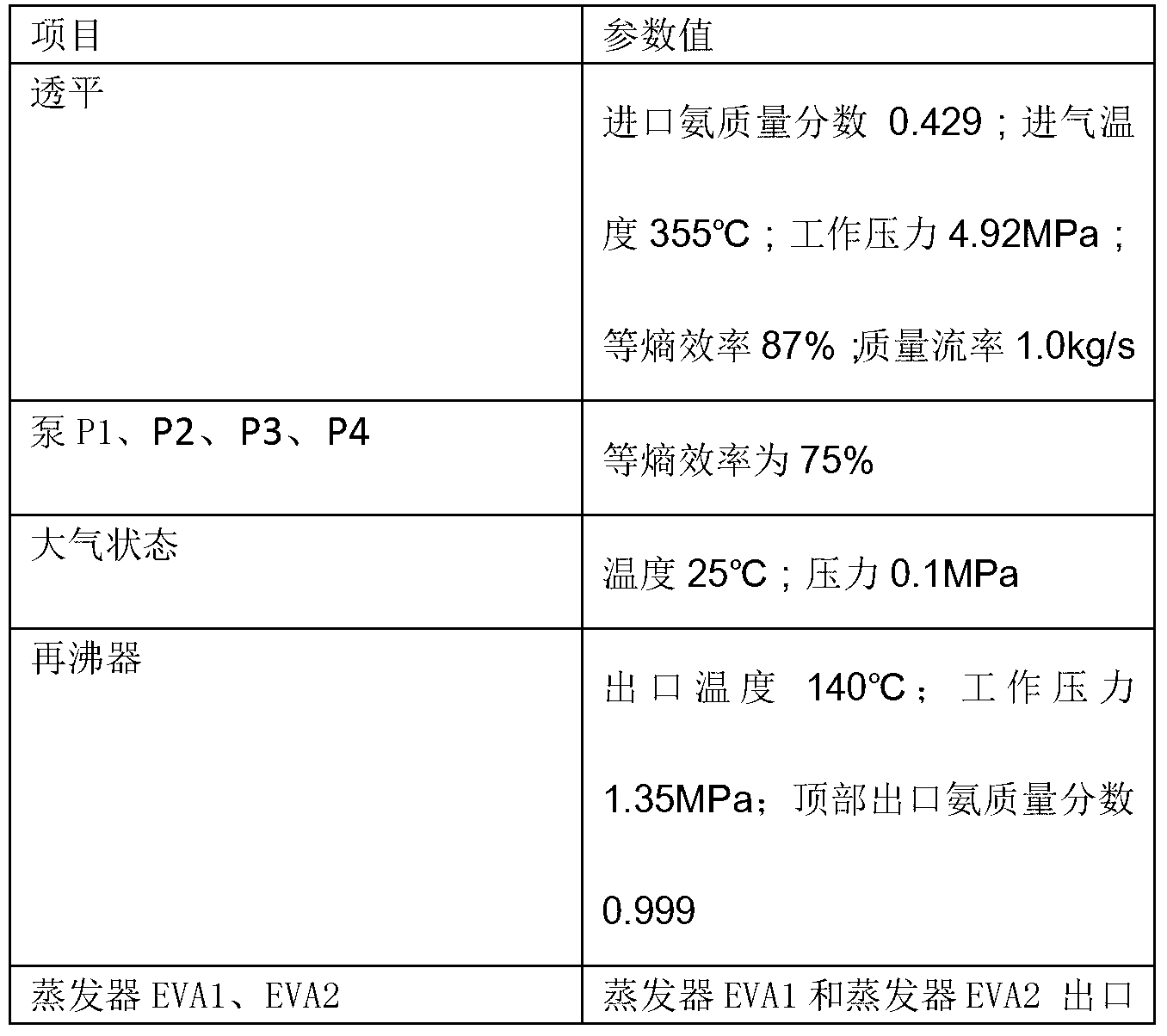

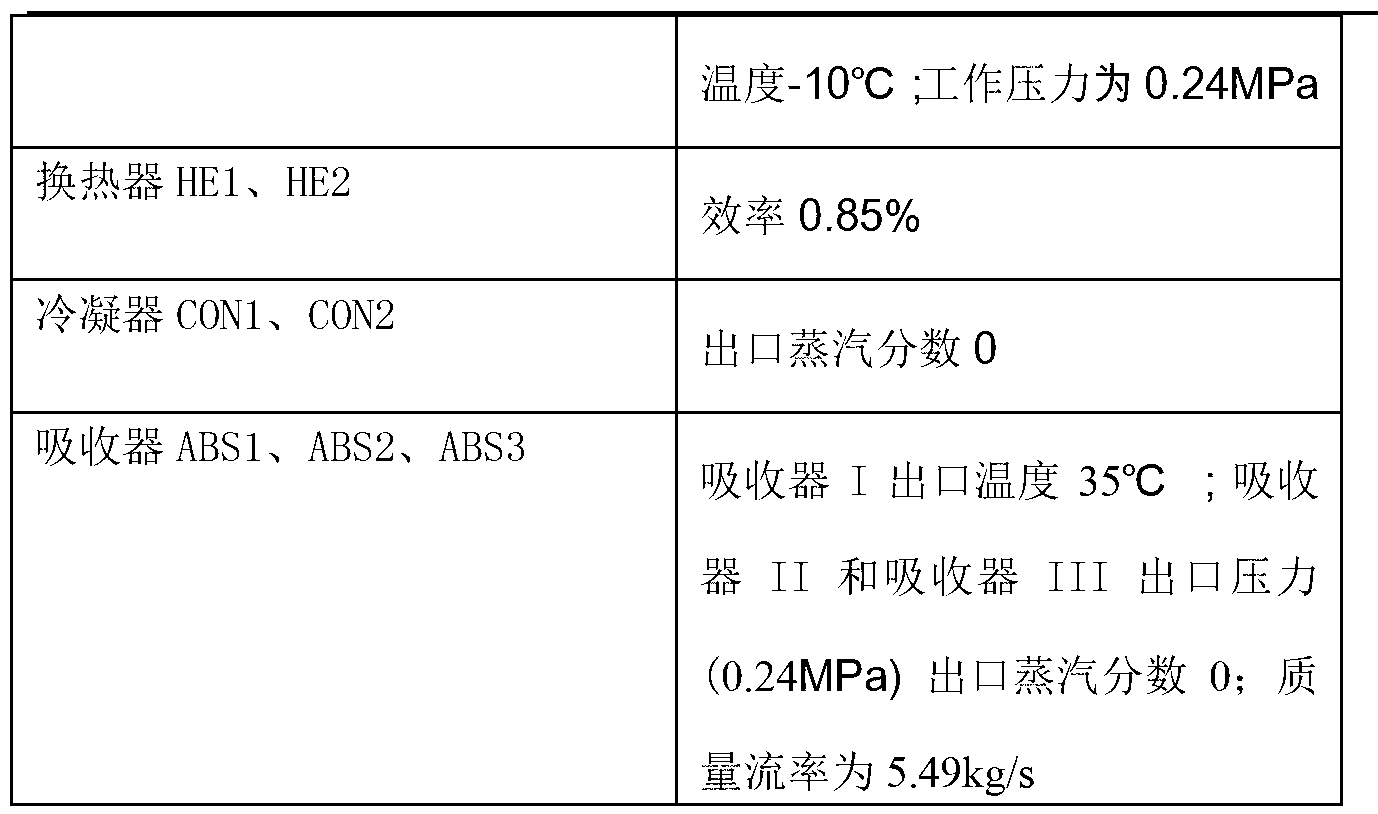

[0012] figure 1 Among them, the present invention includes ammonia power / refrigeration cycle system and absorption refrigeration cycle system wherein ammonia power / refrigeration cycle system contains an evaporator EVA1 and absorber ABS1 and absorber ABS2; Absorption refrigeration cycle system contains an evaporator EVA2 and absorption device ABS3.

[0013] The ammonia power / refrigeration cycle system also includes heat exchanger HE1, boiler, condenser CON1, reboiler REB and turbine. The output pipeline at the top of rectification column REC1 is connected to condenser CON1, and the output pipeline is also connected to evaporator EVA1 , the evaporator EVA1 is connected to the absorber ABS2, the absorber ABS2 is connected to the splitter SP3, and the other path after the diversion of the splitter SP3 is sent to the boiler through the pump P3, the boiler i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com