Quick detecting method of mass content of trace iron in photovoltaic glass

A technology of mass content, photovoltaic glass, applied in color/spectral characteristic measurement, transmittance measurement, etc., can solve the problems of heavy workload, high laboratory conditions, expensive equipment, etc., to improve efficiency, simple instrument requirements, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

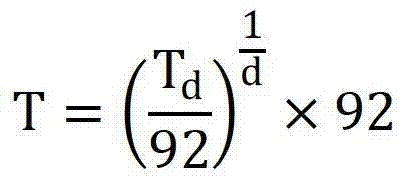

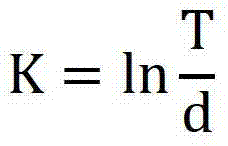

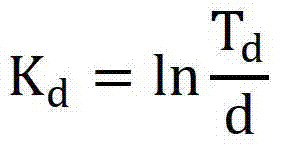

[0052] For photovoltaic glass with a thickness of 3.08mm, the absorbances at 1050nm and 770nm are 0.05371 and 0.047978 respectively. According to formula (7), the mass content of ferrous iron is 0.00689%; the transmittances at 1000nm and 380nm are 0.8888 and 0.9026, respectively. According to formula (10), the mass content of ferric iron is 0.02907%; further, the mass content of total iron is 0.03596%. The total iron mass content measured by X-ray fluorescence spectrometry was 0.0360%, with a relative error of 0.11%.

Embodiment 2

[0054] For photovoltaic glass with a thickness of 5.90mm, the absorbances at 1050nm and 770nm are 0.06313 and 0.05339 respectively, according to the formula (7), the mass content of ferrous iron is 0.00578%; the transmittances at 1000nm and 380nm are 0.8681 and 0.9073 respectively, According to formula (10), the mass content of ferric iron is 0.01066%; further, the mass content of total iron is 0.01644%. The mass content of total iron measured by spectrophotometry was 0.0166%, with a relative error of 0.96%.

Embodiment 3

[0056] For photovoltaic glass with a thickness of 10.00mm, the absorbances at 1050nm and 770nm are 0.10126 and 0.08855 respectively. According to formula (7), the mass content of ferrous iron is 0.00376%; the transmittances at 1000nm and 380nm are 0.7949 and 0.8648, respectively. According to formula (10), the mass content of ferric iron is 0.01201%; further, the mass content of total iron is 0.01577%. The mass content of total iron measured by atomic absorption spectrometry was 0.0157%, with a relative error of 0.45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com