Anti-fouling spark plug and method of making

A technology of spark plugs and coatings, which is applied in the manufacture of spark plugs, spark plugs, liquid chemical plating, etc., and can solve problems such as unqualified durability, reduction, and insufficient accumulation of combustion deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

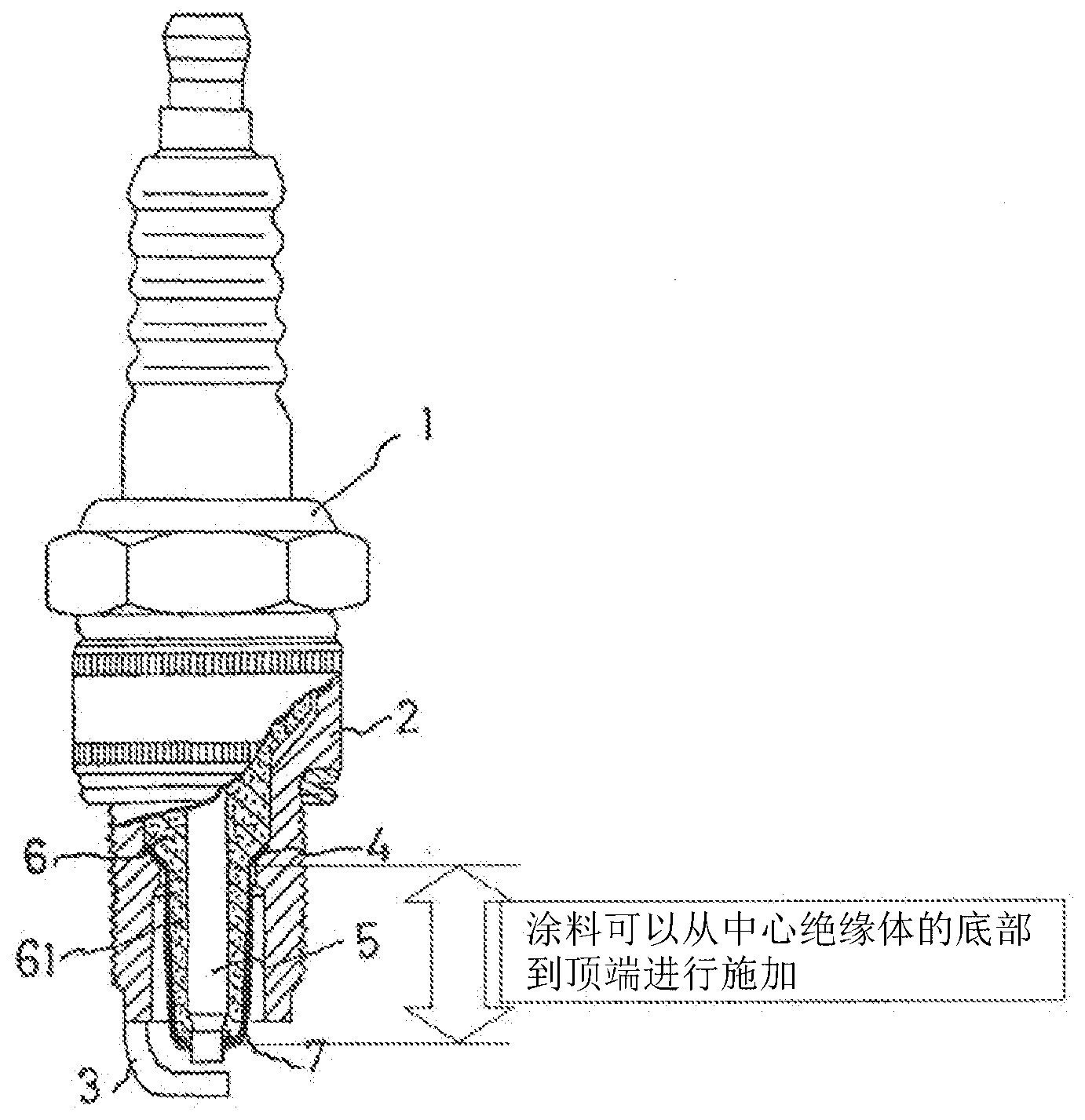

[0011] As described herein, the metal oxide-containing coating is a substantially continuous coating. As defined herein, a substantially continuous coating describes a coating having no cracks or indentations visible to the naked eye and the shaped tip portion of the covering portion, the outer surface of the insulating sleeve. The coating thickness may be 1 to 20 microns thick, or more specifically 5 to 15 microns thick.

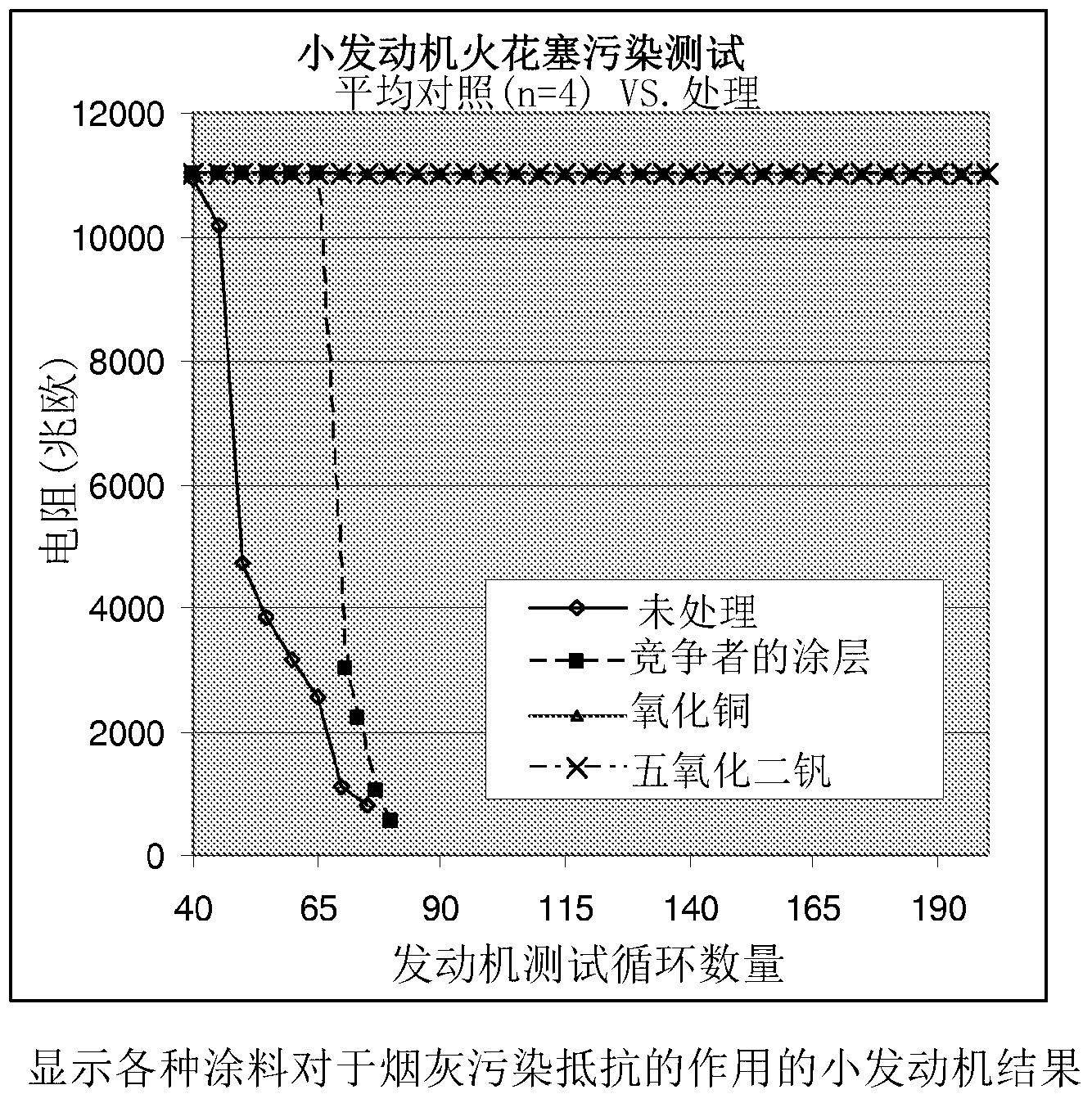

[0012] Suitable metal oxides include barium oxide, copper(II) oxide, manganese oxide, vanadium pentoxide, zinc oxide, zirconium oxide, ceria, molybdenum trioxide, bismuth oxide, tungsten oxide, chromium trioxide, iron oxide ( III), cobalt oxide, nickel (II) oxide, titanium dioxide (anatase), tin oxide, and combinations of two or more of the foregoing metal oxides. Exemplary combinations of metal oxides include ceria and vanadium oxide, vanadium oxide and zirconia, and copper(II) oxide and vanadium oxide.

[0013] It has surprisingly been found that the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com