Method for preparing bean curd by wild jujube and sour bean curd coagulating agent through curdling

A technology of coagulant and tofu, which is applied in the field of tofu preparation and can solve problems such as poor uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

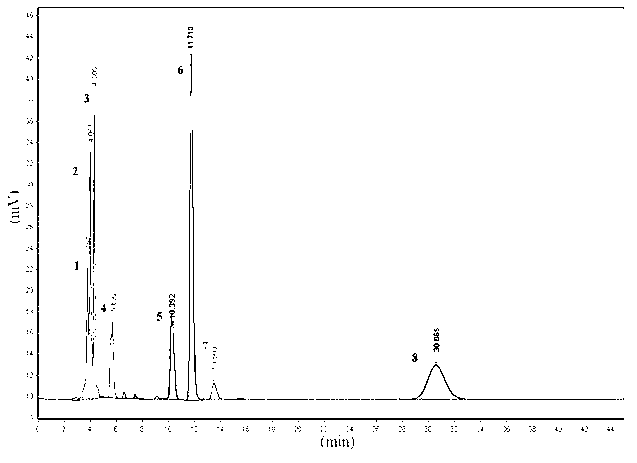

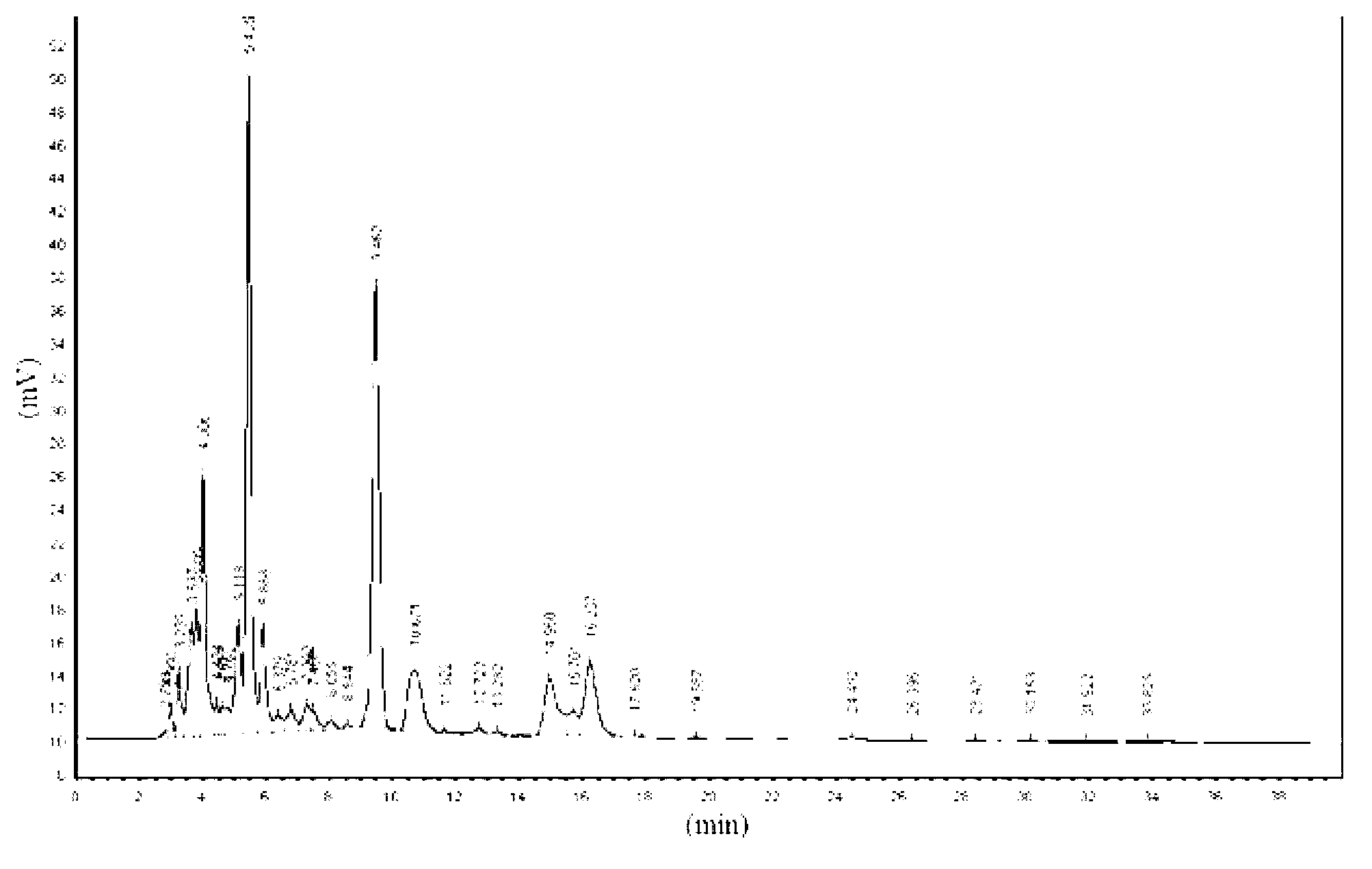

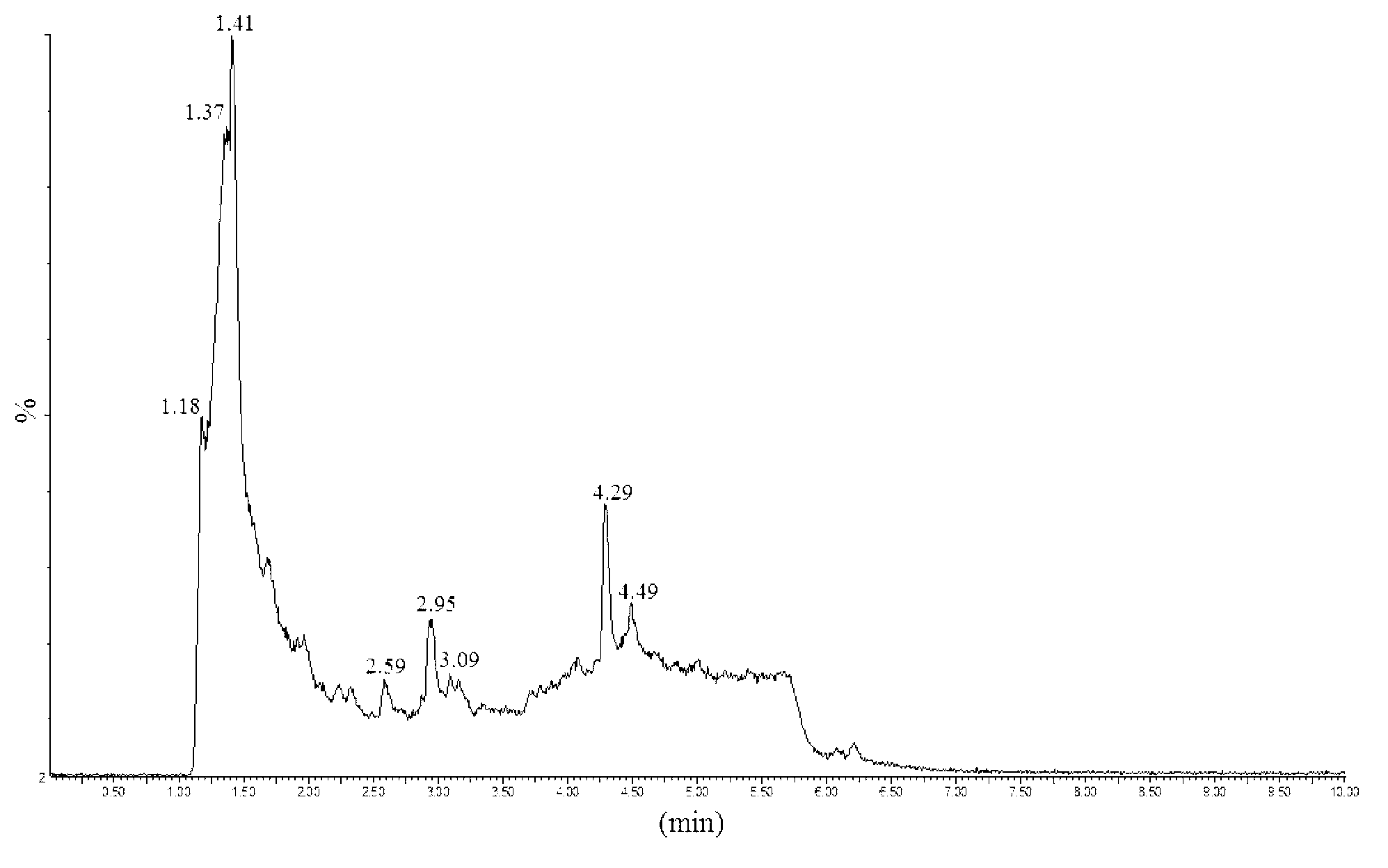

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: present embodiment is a kind of method for making tofu with jujube sour tofu coagulant, specifically completes according to the following steps:

[0021] 1. Soaking: Soak selected soybeans in water for 10-14 hours at room temperature to obtain soaked soybeans;

[0022] 2. Refining, filtering, and boiling pulp: first, put the soaked soybeans and water into the grinder according to the mass ratio of soaked soybeans to water of 1:5, and flow into the grinder at a flow rate of 50mL / min during the grinding process. Add water and add soaked soybeans to the grinder at a feed rate of 15g / min. The slurry obtained by grinding is filtered through double-layer gauze to remove impurities, and then boiled for 3 minutes to 5 minutes in a slow fire, and then boiled in a rapid fire until the slurry is formed. Until the temperature reaches 92°C-98°C, continue to cook with a slow fire until the temperature of the slurry reaches 100°C-102°C, stop the fire and pour ...

specific Embodiment approach 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the selected soybeans described in step 1 are new soybeans with bright color, plump grains, and no insects or rats. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the jujube sour tofu coagulant described in step 4 is specifically prepared according to the following steps: first, the jujube is depitted to obtain nucleic acid-free jujube , add water to the nucleic acid-free jujube and grind to obtain fruit pulp, then produce ultrasonic treatment at an ultrasonic frequency of 175W and a temperature of 65°C for 15min, cool to room temperature and centrifuge at a speed of 3000r·min -1 Centrifuge for 10 minutes, vacuum filter the centrifuged supernatant obtained by centrifugal separation with a 0.45 μm filter membrane, then concentrate the volume of the supernatant obtained by vacuum filtration to 1 / 3 of the original volume, and then put it in an autoclave Sterilize for 10 minutes and cool to room temperature to obtain the jujube sour tofu coagulant; the volume ratio of the nucleic acid-free jujube to water is 1g:9mL. Others are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com