Cigarette purifying and harm-reducing reagent and particles and preparation method of cigarette and particles

A granule and cigarette technology, applied in the field of granule preparation, can solve the problems of weakening the identification of harmful gases and not reducing low-molecular-weight aldehydes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the purification harm reduction particle of cigarette of the present invention is as follows:

[0032] During preparation, sodium alginate was dissolved in water to make aqueous solution A;

[0033] In addition, the plant extract is dissolved in water, then glycerin or propylene glycol is added, and then stirred at room temperature to form an aqueous solution B;

[0034] Crush the seafood, pass through a 40-mesh sieve, mix it with active starch in any proportion and add the aqueous solution A to the above mixture, mix evenly, and use a multi-functional pellet coating machine to make small particles of 3mm to 6mm. Rapidly drying and activating at a temperature of ℃ to make porous, large specific surface area, polar, hydrated ions, and non-toxic composite carrier particles C;

[0035] Coat the prepared aqueous solution B on the particle surface, and quickly dry it at a temperature of 70-90°C to make a finished product; or soak the composite carr...

Embodiment 1

[0039] In this embodiment, the preparation method of the purification and harm reduction particles of cigarettes comprises the following steps:

[0040] 1. Dissolve 0.3g of sodium alginate into 30g of water to make aqueous solution A;

[0041] 2. Take 20g of Coptis chinensis extract, add 5.0g of propylene glycol and water to form 45g of aqueous solution B;

[0042] 3. Crush the coral sand through a 40-mesh sieve, add active starch in a ratio of 1:1 and mix evenly to form a mixture;

[0043] 4. Add the aqueous solution A to the mixture described in step 3, granulate after mixing evenly, then dry and activate to make porous, large specific surface area, polar, hydrated ion, non-toxic composite carrier particle C;

[0044] 5. Coat the prepared aqueous solution B on the surface of C particles, and quickly dry it at a temperature of 70°C to make a finished product.

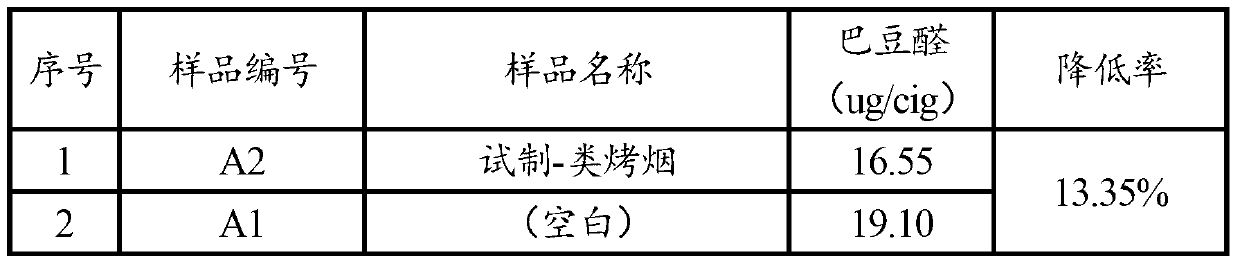

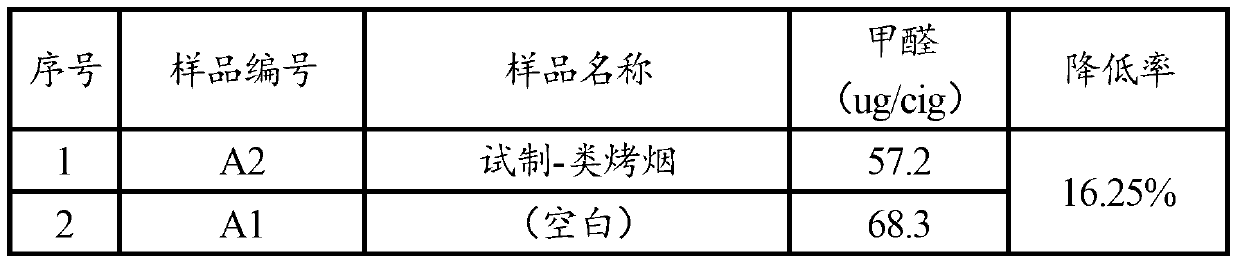

[0045] Take 2 parts of sample flue-cured tobacco, one part of the filter stick of flue-cured tobacco is added the ...

Embodiment 2

[0050] In this embodiment, the preparation method of the purification and harm reduction particles of cigarettes comprises the following steps:

[0051] 1. Dissolve 0.5g of sodium alginate into 40g of water to make aqueous solution A;

[0052] 2. Take 25g of geranium extract, add 7.0g of propylene glycol to make 50g of aqueous solution B;

[0053] 3. Crush coral sand and sea octopus through a 40-mesh sieve, add active starch in a ratio of 1:1.5:1 and mix evenly to form a mixture;

[0054] 4. Add the aqueous solution A to the mixture described in step 3, granulate after mixing evenly, dry and activate to make porous, large specific surface area, polar, hydrated ion, non-toxic composite carrier particle C;

[0055] 5. Coat the prepared aqueous solution B on the surface of the composite carrier particle C, and quickly dry it at a temperature of 85°C to make a finished product;

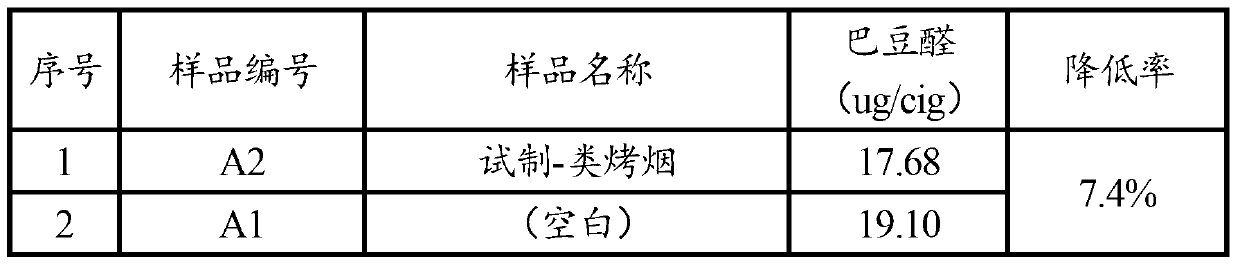

[0056] Take 2 parts of sample flue-cured tobacco, one part of the filter stick of flue-cured tobacco i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com