Surface grafting modified aromatic polyamide composite reverse osmosis membrane and preparation method thereof

A technology of surface graft modification and aromatic polyamide, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem of no antibacterial performance, discontinuous antibacterial performance on the membrane surface, and blank antibacterial performance on the membrane surface Issues such as antibacterial function and anti-biological pollution performance, high chlorine resistance performance and anti-biological pollution performance, and easy implementation are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

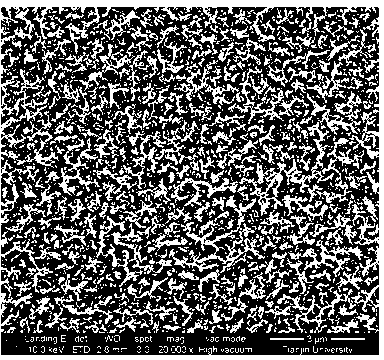

Embodiment 1

[0019] A rectangular commercial reverse osmosis membrane with a size of 13 cm×11 cm is fixed in a polytetrafluoroethylene frame, which can ensure that only the upper surface of the membrane (aromatic polyamide separation layer) is in contact with the reaction during the entire grafting reaction. The surface of the aromatic polyamide composite reverse osmosis membrane was washed with deionized water for 5 min, and then the surface of the membrane was purged with nitrogen to dryness; 1.06g of 1-(3-dimethylaminopropyl)-3-ethylcarbodi Imine hydrochloride was added to 25 mL of deionized water, and the aqueous solution was poured on the surface of the membrane, and allowed to stand in the dark for 10 min to react. After the reaction is complete, add 0.53g of N-hydroxysuccinimide directly to the aqueous solution on the surface of the membrane, shake it slowly to dissolve it completely, and then let it stand in the dark for 10 minutes; add 1.32g of ethylenediamine to 25mL Then pour th...

Embodiment 2

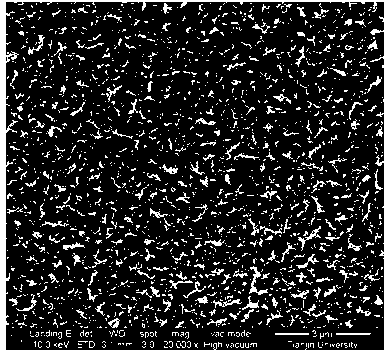

[0025] A rectangular commercial reverse osmosis membrane with a size of 13 cm×11 cm is fixed in a polytetrafluoroethylene frame, which can ensure that only the upper surface of the membrane (aromatic polyamide separation layer) is in contact with the reaction during the entire grafting reaction. The surface of the aromatic polyamide composite reverse osmosis membrane was rinsed with deionized water for 5 min, and then the surface of the membrane was purged with nitrogen to dryness; 1.65g of 1-(3-dimethylaminopropyl)-3-ethylcarbodi Imine hydrochloride was added to 25 mL of deionized water, and the aqueous solution was poured on the surface of the membrane, and allowed to stand in the dark for 15 min to react. After the reaction is complete, directly add 0.82g of N-hydroxysuccinimide to the aqueous solution on the surface of the membrane, shake it slowly to dissolve it completely, and then let it stand in the dark for 15 minutes; add 1.32g of ethylenediamine to 25mL Then pour th...

Embodiment 3

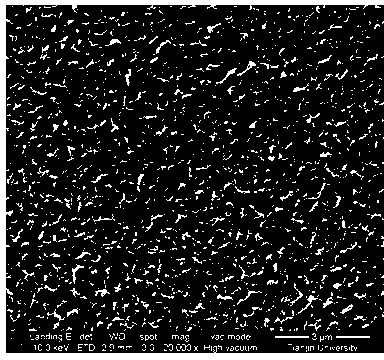

[0029] A rectangular commercial reverse osmosis membrane with a size of 13 cm×11 cm is fixed in a polytetrafluoroethylene frame, which can ensure that only the upper surface of the membrane (aromatic polyamide separation layer) is in contact with the reaction during the entire grafting reaction. The surface of the aromatic polyamide composite reverse osmosis membrane was rinsed with deionized water for 5 min, and then the surface of the membrane was purged with nitrogen to dryness; 2.27g of 1-(3-dimethylaminopropyl)-3-ethylcarbodi Imine hydrochloride was added to 25 mL of deionized water, and the aqueous solution was poured on the surface of the membrane, and left to react in the dark for 20 min. After the reaction is complete, add 1.14g of N-hydroxysuccinimide directly to the aqueous solution on the surface of the membrane, shake it slowly to dissolve it completely, and then let it stand in the dark for 20 minutes; add 1.32g of ethylenediamine to 25mL Then pour the solution o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com