Three-power-source bus and power solution method

A bus and three-power technology, which is applied to the arrangement of multiple different prime movers of the power plant, the general power plant, and the air pressure power plant, etc., can solve the problems of large investment, high construction cost, large noise pollution and environmental pollution, etc. Problems, achieve the effect of reducing the requirements for power storage capacity, reducing air pollution, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

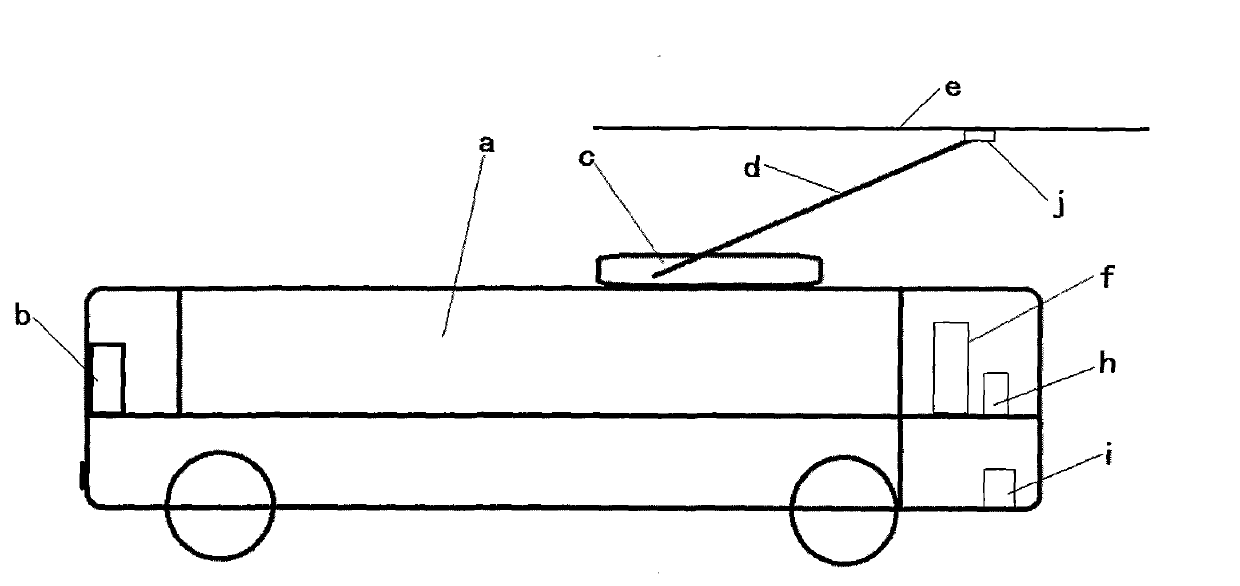

[0024] combined with figure 1 , to further describe the present invention:

[0025] A bus with three power sources is characterized in that it includes a car body a, an automatic control system b, a catenary connector c, a power catenary connection line d, a power catenary e, a power receiver j and power equipment, the car body The cab of a is equipped with an automatic control system b, the top of the car body a is equipped with a catenary connector c, and the catenary connector c is equipped with a power catenary connection line d, and the power catenary connection line d is connected to a power receiver j is connected to the electric catenary e, and the power equipment includes a fuel engine f, an electric motor h, and a capacitor storage device i.

[0026] The above-mentioned power catenary e is an intermittent power catenary.

[0027] The above-mentioned discontinuous power catenary supplies power separately between each road section.

[0028] 5. A power solution for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com