On-line cooling method using hydrogen in optical fiber drawing process

A cooling method, hydrogen technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high cost and low cooling efficiency, and achieve the effects of convenient supply, good cooling effect and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

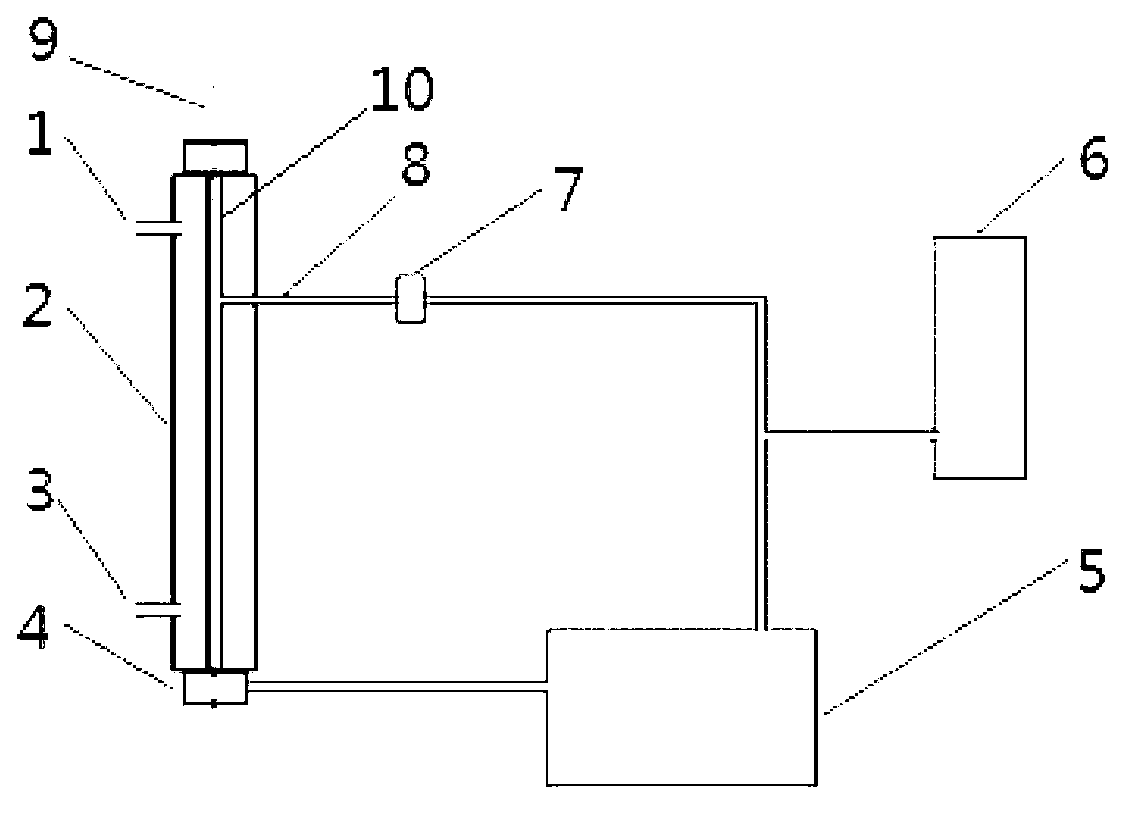

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0018] The present invention comprises the following steps:

[0019] (1) The optical fiber coming out of the graphite furnace passes through the caliper and defect meter to the cooling pipe of the cooling device in turn, and the drawing speed gradually increases;

[0020] (2) When the drawing speed reaches 300-500mpm, the hydrogen recovery and purification device starts to work;

[0021] (3) When the wire drawing speed reaches 800mpm, the hydrogen gas supply device starts to work, hydrogen gas is filled into the cooling gas pipeline, and the downward movement of the optical fiber drives the hydrogen gas to go downward. During the movement, the temperature of the optical fiber surface is absorbed by the hydrogen gas; And the hydrogen is in full co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com