Edible ink for ink-jet printing on surface of chocolate and preparation method thereof

An inkjet printing and chocolate technology, which is applied in the field of edible ink and its preparation, can solve the problems that the image durability cannot meet the needs of use, the difficulty of saving stable printing images, and the immature preparation technology, so as to achieve a good market prospect and increase the market. Competitiveness and appetite-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

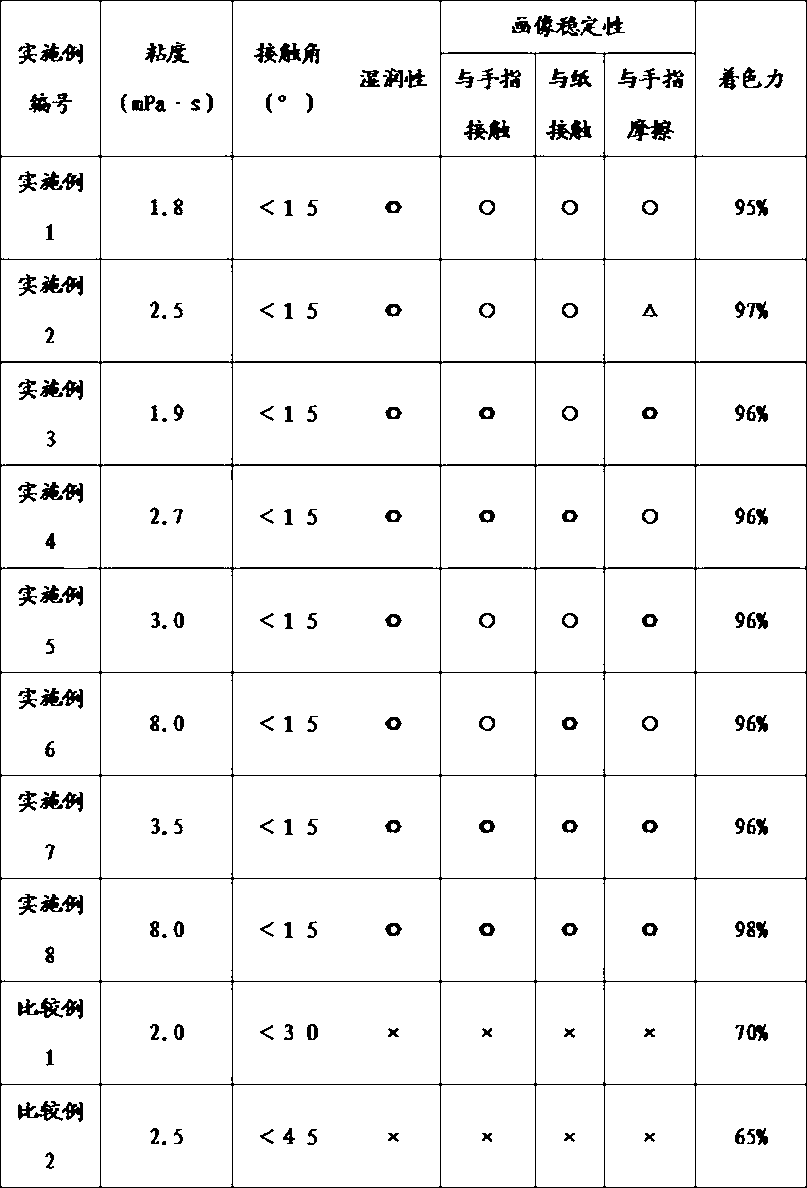

Examples

Embodiment 1

[0030] (a) Dissolving emulsifier: 0.1wt% sucrose fatty acid and 99.89wt% sterile distilled water were continuously stirred at 35°C until completely dissolved and homogenized to form liquid sucrose fatty acid;

[0031] (b) Ingredients: add 0.01wt% of beet red pigment into liquid sucrose fatty acid, and stir continuously to obtain a uniformly mixed solution;

[0032] (c) Filtration: use filter paper with a pore size of 0.5 μm to filter the solution obtained in step (b) under reduced pressure to obtain the product.

Embodiment 2

[0034] (a) Dissolving emulsifier: 0.1% trehalose, 50wt% glycerin fatty acid ester and 9.9wt% deionized water were continuously stirred at 120°C until completely dissolved and homogenized to form a liquid emulsifier;

[0035] (b) Ingredients: adding 40wt% curcumin into the liquid emulsifier, stirring continuously to obtain a uniformly mixed solution;

[0036] (c) Filtration: use filter paper with a pore size of 0.5 μm to filter the solution obtained in step (b) under reduced pressure to obtain the product.

Embodiment 3

[0038] (a) Dissolving emulsifier: 50wt% of maltose, 1wt% of sorbitan fatty acid ester and 48.9wt% of sterile distilled water were continuously stirred at 40°C until completely dissolved and homogenized to form a liquid emulsifier;

[0039] (b) Ingredients: add 0.1wt% chlorophyll into the liquid emulsifier, and stir continuously to obtain a uniformly mixed solution;

[0040] (c) Filtration: use filter paper with a pore size of 0.5 μm to filter the solution obtained in step (b) under reduced pressure to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com