Ice coating prevention paint for power transmission cable and preparation method thereof

A power transmission cable, anti-icing technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocide, etc., can solve problems such as poor anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

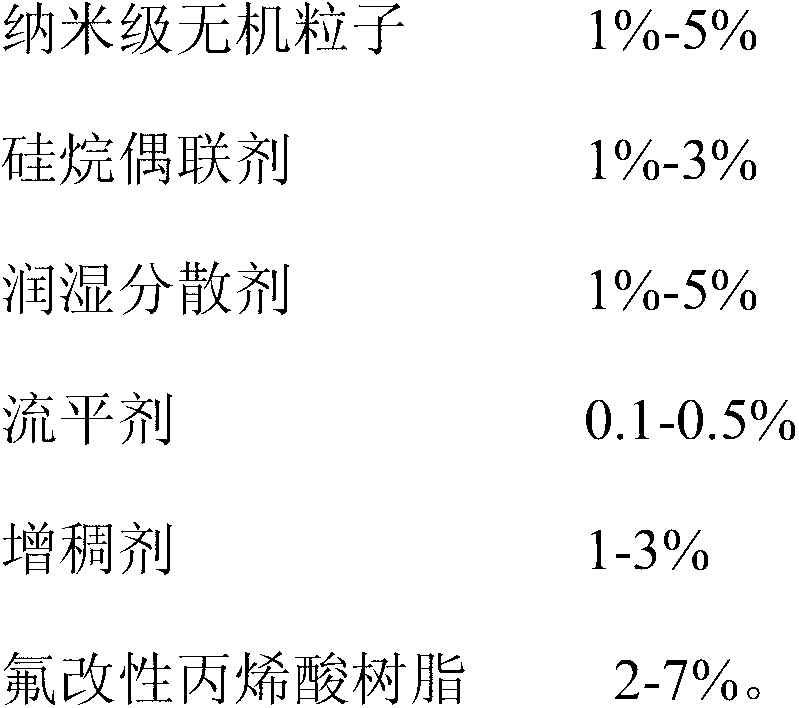

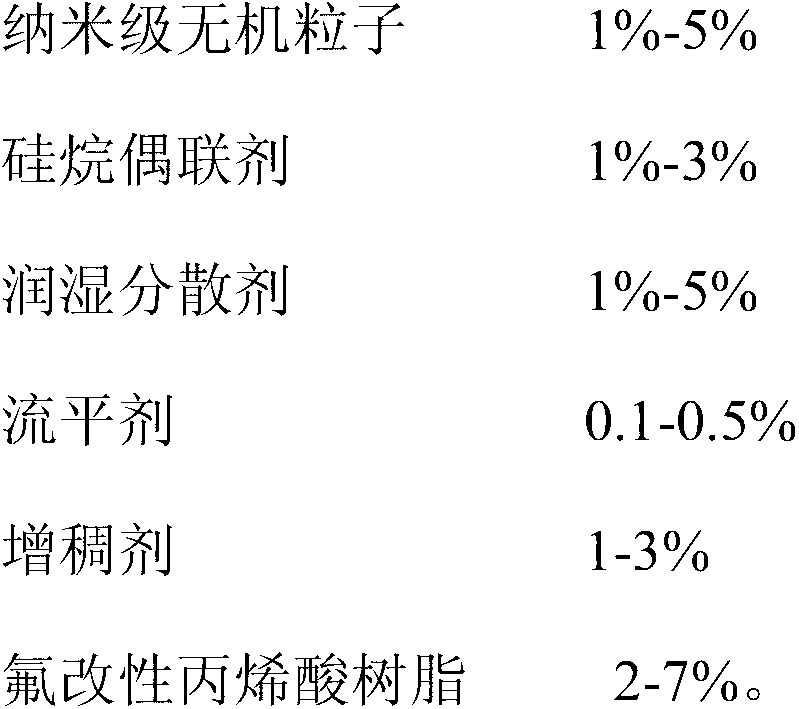

Method used

Image

Examples

Embodiment 1

[0018] The solvent is N,N-dimethylformamide, based on the solvent quality, add 1wt.% nano-sized SiO to the solvent 2 , 1.5wt.% vinyl triethoxysilane, 1wt.% branched polycarboxylic acid, use mechanical stirring until uniform and then ultrasonically disperse for 3 minutes; then add 0.1wt.% German BYK-301 fluid Leveling agent, 3wt.% organobentonite 881-B and 2wt.% fluorine-modified acrylic resin produced by Harbin Xuejia Fluoro-Silicon Chemical Co., Ltd., mechanically stir the mixed solution until it is uniform, and then ultrasonically disperse it for 3 minutes to obtain the compound of the present invention The anti-icing transmission cable coating described above.

[0019] This anti-icing power transmission cable coating is coated on a glass plate, and the coating is formed after the solvent in the coating is completely volatilized. The contact angle of water droplets falling on the coating surface is measured to be 160°, which shows that the coating formed by this coating has ...

Embodiment 2

[0021] The solvent is N,N-dimethylformamide, based on the solvent quality, add 1wt.% nano TiO to the solvent 2 and 4wt.% nanoscale SiO 2 , 2wt.% Propyltrimethoxysilane (KH-560), 4wt.% branched polycarboxylic acid, use mechanical stirring until uniform and then ultrasonically disperse for 6min; then add 0.4wt.% German BYK BYK -301 leveling agent, 3wt.% organic bentonite 881-B and 5wt.% fluorine-modified acrylic resin produced by Harbin Xuejia Fluoro-Silicon Chemical Co., Ltd., mechanically stir the mixture until it is uniform, and then ultrasonically disperse it for 8 minutes to obtain The anti-icing power transmission cable coating of the invention.

[0022] The anti-icing power transmission cable coating is coated on a glass plate, and the coating is formed after the solvent in the coating is completely volatilized. The contact angle of water droplets falling on the coating surface is measured to be 167°, which shows that the coating formed by this coating has strong Hydrop...

Embodiment 3

[0024] The solvent is toluene, based on the solvent quality, add 1wt.% nano TiO to the solvent 2 , 3wt.% vinyltriethoxysilane, 3wt.% polycarboxylic acid and polyamine oligomers, use mechanical stirring until uniform and then ultrasonically disperse for 2min; then add 0.2wt.% German Bi Gram BYK-331 leveling agent, 2wt.% fumed silica R972 and 7wt.% fluorine-modified acrylic resin produced by Harbin Xuejia Fluoro-Silicon Chemical Co., Ltd., mechanically stir the mixture until it is uniform, and then ultrasonically disperse it for 6 minutes. The anti-icing power transmission cable coating of the present invention is obtained.

[0025] The anti-icing power transmission cable coating is coated on a glass plate, and the coating is formed after the solvent in the coating is completely volatilized. The contact angle of water droplets falling on the coating surface is measured to be 170°, which shows that the coating formed by this coating has strong Hydrophobic; after the coating is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com