Quasi-solid electrolyte and preparation method thereof

A quasi-solid-state, electrolyte technology, applied in the direction of capacitor electrolyte/absorbent, photovoltaic power generation, photosensitive equipment, etc., can solve the problems of easy leakage and difficult sealing of batteries, so as to solve the problems of difficult sealing and easy leakage, and improve long-term stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

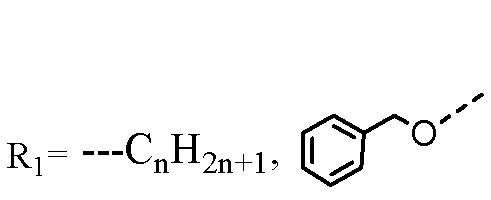

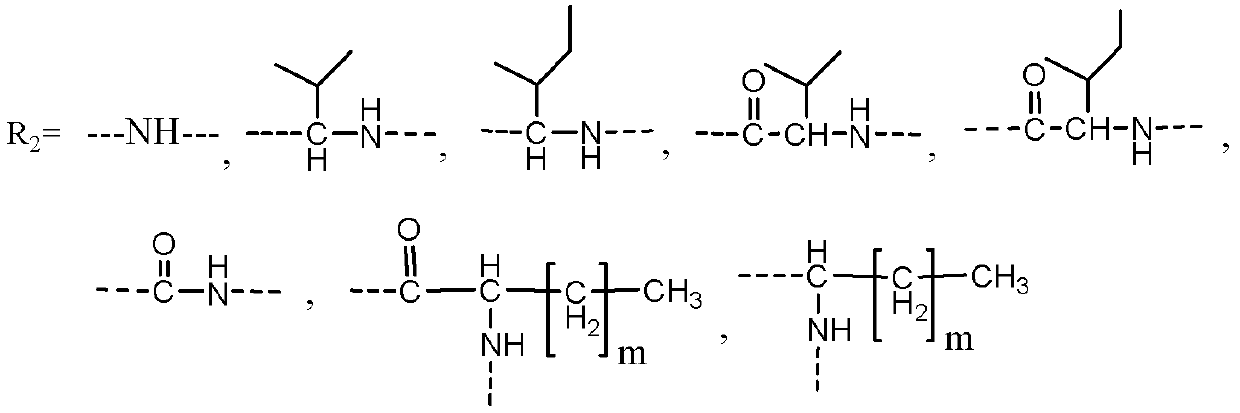

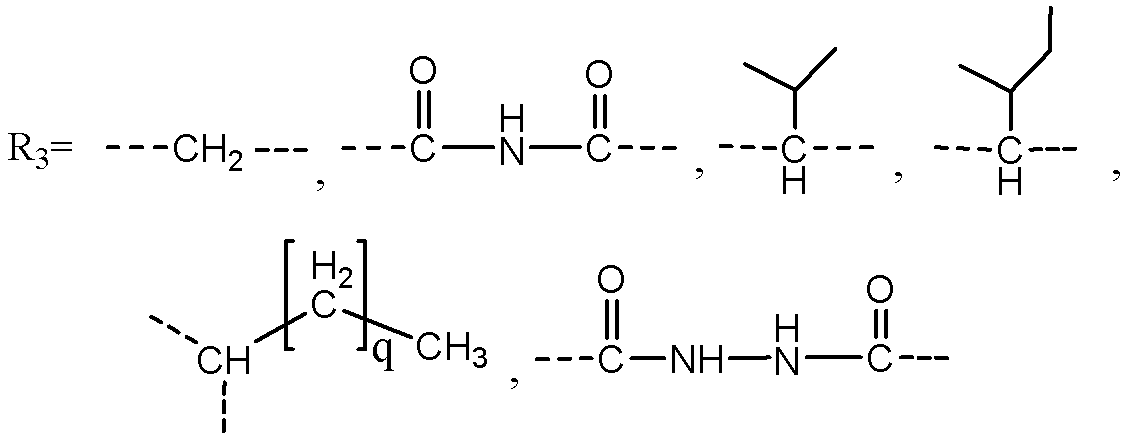

Embodiment 1

[0084] In a glove box filled with high-purity nitrogen, weigh 0.028 g, 0.053 g, 1.54 g, 0.24 g, and 0.57 g of lithium iodide, iodine, acetonitrile, 4-tert-butylpyridine, 1,2-dimethyl- 3-Propyl imidazolium iodine. Place the weighed lithium iodide, iodine, 3-methoxypropionitrile, N-methylbenzimidazole, and 1,2-dimethyl-3-propylimidazole iodine in a sealable clean container, Ultrasonic dispersion was performed for 15 minutes to form a uniform electrolyte, and 0.15 g of an amide small-molecule gelling agent with n and m both 12, x and z both 1 and y 0 was added to it. Seal the container, heat the mixture in the container to 135°C, stir the system uniformly with magnetic stirring, and keep it for 30 minutes. After the mixed system is cooled to room temperature, the quasi-solid gel electrolyte Gel0 can be obtained.

[0085] Using electrochemical workstation to do cyclic voltammetry test, get the I of quasi-solid gel electrolyte Gel0 3 - The steady-state diffusion current and app...

Embodiment 2

[0088] In a glove box filled with high-purity nitrogen, weigh 0.028 g, 0.053 g, 1.8 g, 0.14 g, and 0.57 g of lithium iodide, iodine, 3-methoxypropionitrile, N-methylbenzimidazole, 1 , 2-Dimethyl-3-propylimidazolium iodide. Place the weighed lithium iodide, iodine, 3-methoxypropionitrile, N-methylbenzimidazole, and 1,2-dimethyl-3-propylimidazole iodine in a sealable clean container, Ultrasonic dispersion was performed for 15 minutes to form a uniform electrolyte, and then 0.15 g of an amide small-molecule gelling agent whose n and m were 12, x and z were both 1, and y was 1 was added to it. Seal the container, heat the mixture in the container to 130°C, stir the system uniformly with magnetic stirring, and keep it for 30 minutes. After the mixed system is cooled to room temperature, the quasi-solid gel electrolyte Gel1 can be obtained.

[0089] Using the electrochemical workstation to do cyclic voltammetry test, get the I of quasi-solid gel electrolyte Gel1 3 - The steady-s...

Embodiment 3

[0092] In a glove box filled with high-purity nitrogen, weigh 0.028 g, 0.053 g, 1.8 g, 0.14 g, and 0.57 g of lithium iodide, iodine, 3-methoxypropionitrile, N-methylbenzimidazole, 1 , 2-Dimethyl-3-propylimidazolium iodide. Place the weighed lithium iodide, iodine, 3-methoxypropionitrile, N-methylbenzimidazole, and 1,2-dimethyl-3-propylimidazole iodine in a sealable clean container, Ultrasonic dispersion was performed for 15 minutes to form a uniform electrolyte, and then 0.15 g of an amide small-molecule gelling agent whose n and m were both 12, x and z were both 1, and y was 2 was added to it. Seal the container, heat the mixture in the container to 130°C, stir the system uniformly with magnetic stirring, and keep it for 30 minutes. After the mixed system is cooled to room temperature, the quasi-solid gel electrolyte Gel2 can be obtained.

[0093] Using electrochemical workstation to do cyclic voltammetry test, get the I of quasi-solid gel electrolyte Gel2 3 - The steady-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com