Packaging process capable of improving stability of ionic polymer metal composite (IPMC) driver

A packaging process and driver technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the problems of reverse relaxation, difficulty in accurately controlling internal water content, performance attenuation, etc., and reduce the curing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Parylene Coated IPMC Driver Package

[0027] (1) Make the IPMC driver and connect the lead electrodes

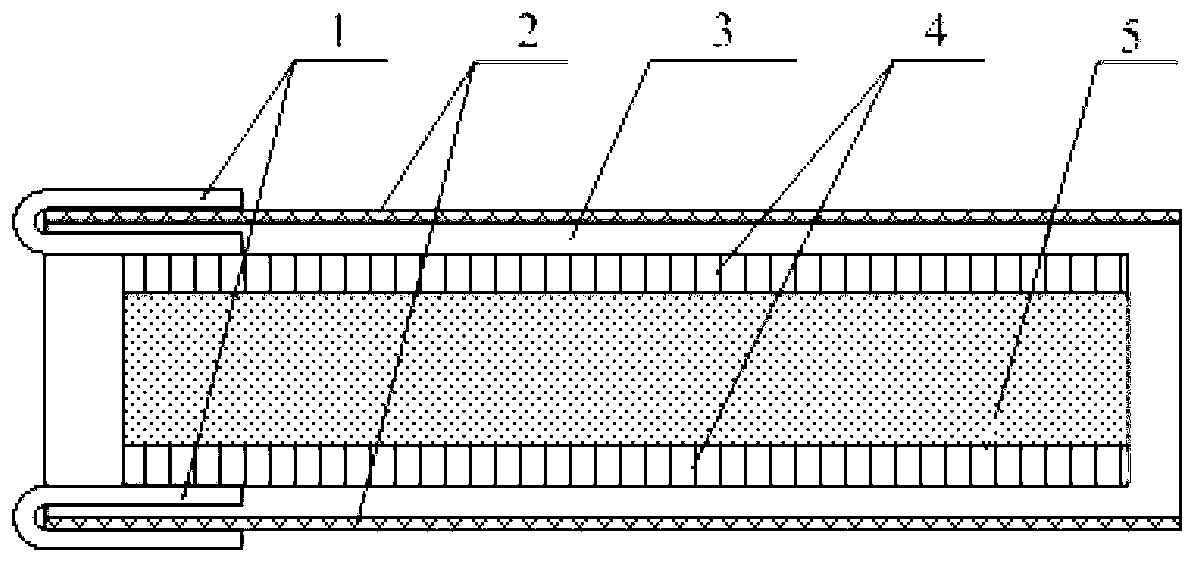

[0028] Connect upper and lower surface electrodes 4 respectively at the IPMC core layer ionic membrane 5 to form an IPMC driver; make two initial extraction electrodes 1, one of which is bonded to the edge of the upper surface electrode at one end of the IPMC driver, and the other is bonded to the end of the IPMC driver. Edge bonding of surface electrodes ( figure 1 ), and then put the IPMC driver with the initial lead-out electrode 1 into the bracket above the solution filled with saturated NaCl at the bottom of the airtight container to exchange and balance for 1 hour. The humidity reading above the solution was measured by a hygrometer as RH70%, so it is considered The material is exchanged and balanced in a humidity environment of RH70%.

[0029] The initial lead-out electrode 1 is cut into a 10mm×5mm electrode sheet with a conductive copper foil, and can also b...

Embodiment 2

[0035] Dense Oxide Coated IPMC Driver Package

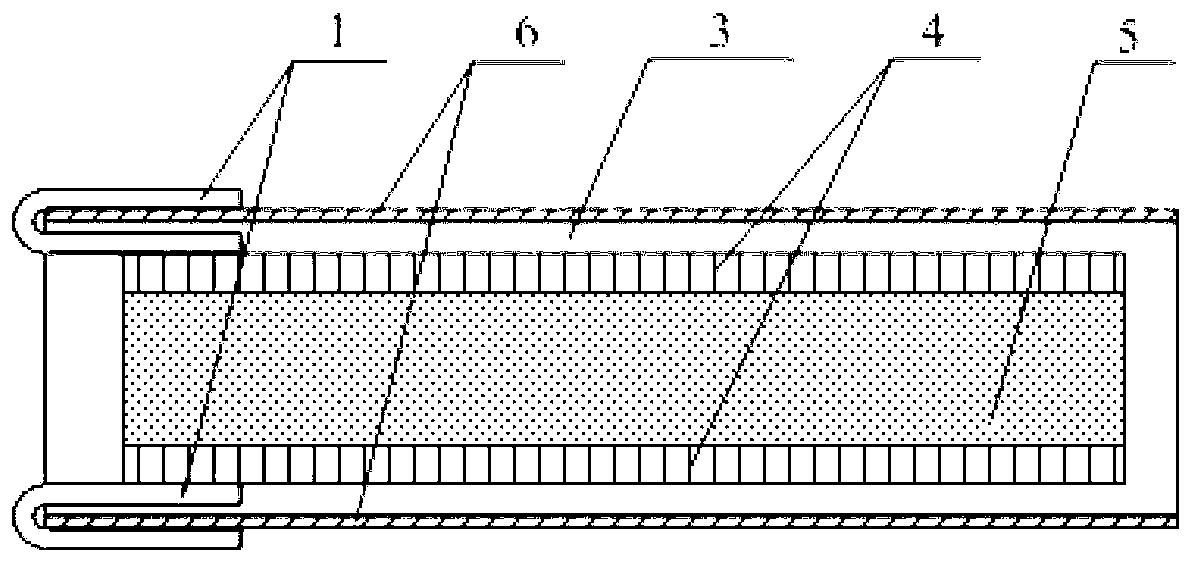

[0036] Deposit a 3um thick dense oxide coating 6 (aluminum oxide, silicon oxide or titanium oxide, etc.) on the surface of the pre-packaged photo-curing coating 3 of the driver using a normal temperature magnetron sputtering process, place the target and the IPMC material driver, and adjust Magnetron sputtering process parameters: vacuum degree 2×10 -5 torr, power supply 200W, argon gas rate 20sccm; other steps are the same as in Example 1. After encapsulation, get as figure 2 structure shown.

Embodiment 3

[0038] Photocuring adhesive bonding high barrier material IPMC driver package

[0039] (1) Make the IPMC driver and connect the lead electrodes

[0040] Same as step (1) in Example 1.

[0041] (2) Using UV-curable coatings as the adhesive, using the model H-Barrier produced by Mitsubishi, with a thickness of 10um as the upper and lower barrier base film, and using the N-Barrier produced by Norland O A74 light-curing glue is coated on the inner layer of the upper and lower base films, and the glue coating area should cover the upper and lower surfaces of the IPMC driver, and the inner layer of the upper and lower barrier base films is pasted on the upper and lower surface electrodes of the IPMC driver (including the connection with the initial lead-out electrode) , and apply pressure to the outer layers of the upper and lower barrier base films to make the encapsulation layer thin and flat.

[0042](3) Put the whole driver under a UV lamp and treat the front and back sides fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com