Millimeter wave micropore coupler for measuring high power

A pinhole coupling, millimeter wave technology, applied in waveguide-type devices, electrical components, connecting devices, etc., can solve problems such as inability to measure high-power microwaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

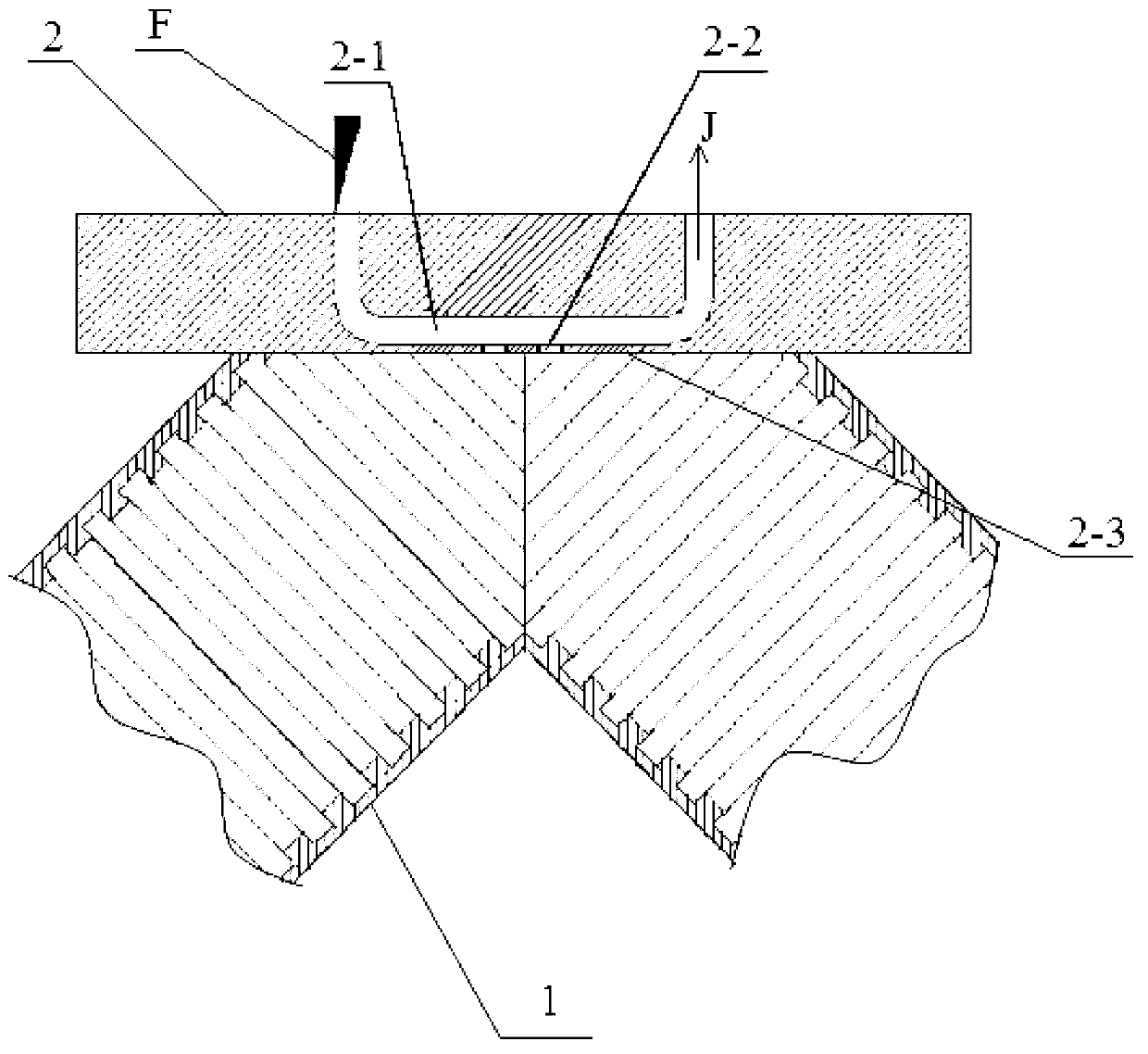

[0015]This embodiment takes the small hole coupler used for measuring the transmission power of the ECRH (electron cyclotron resonance heating) system corrugated waveguide transmission line with an inner diameter of φ63.5mm and a material of 6061-T6 aluminum alloy as an example: Among them, the inner diameter of the corrugated waveguide transmission line 1 is φ63. 5mm, the depth of each corrugated groove is 0.41mm, the groove width is 0.46mm, the period is 0.66mm, and the outer diameter is φ76.2mm. 2 (that is, the ratio of the area of the ring mouth to the cross-sectional area of the corrugated waveguide cavity is 1.29), the cut plane and the center line of the transmission line on both sides of the elbow are at an angle of 45° and perpendicular to the plane formed by the two center lines; the coupler body 2 The thickness is 11.48mm, the radius size is 61.40mm, and the "U"-shaped waveguide 2-1 adopts the R1400 standard rectangular waveguide size, that is, the nominal width ...

Embodiment 2

[0018] In this embodiment, a coupling hole 2-2 is opened at the center of the reflection surface 2-3 as a coupling channel between the bottom section of the "U" shape waveguide 2-1 and the right-angle elbow on the corrugated waveguide transmission line 1. Take a coupler connected to the inner cavity as an example. The two coupling holes 2-2 are symmetrically distributed along the length direction of the bottom section of the "U" waveguide with the center of the mirror as the reference. The height (depth) of each hole is 0.3mm, and the radius is R0.23mm. The hole pitch is 0.75mm, and the rest are the same as in Example 1.

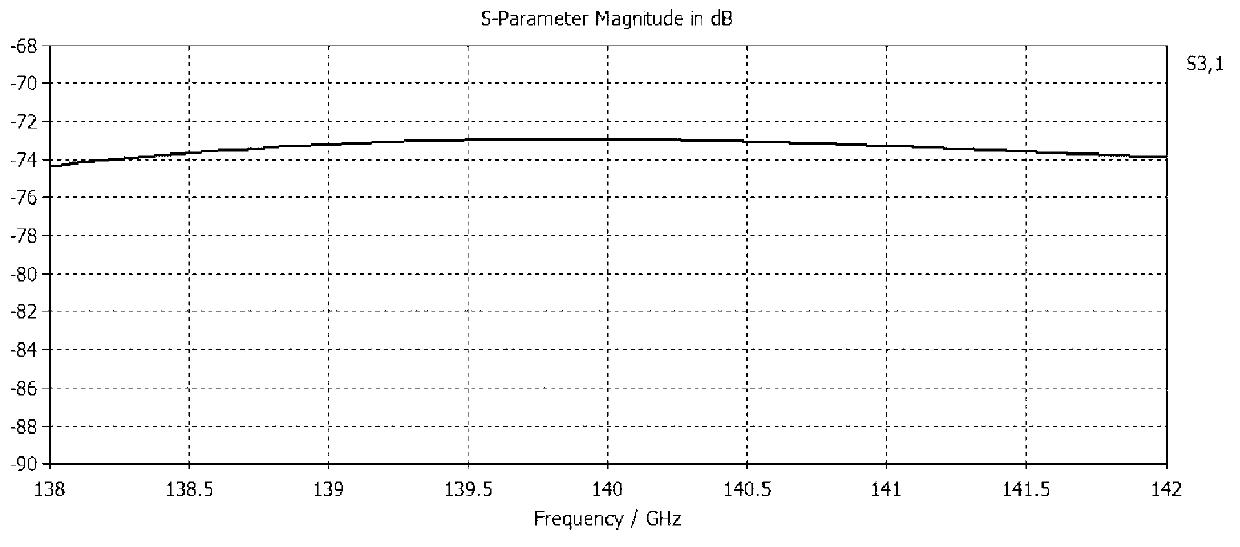

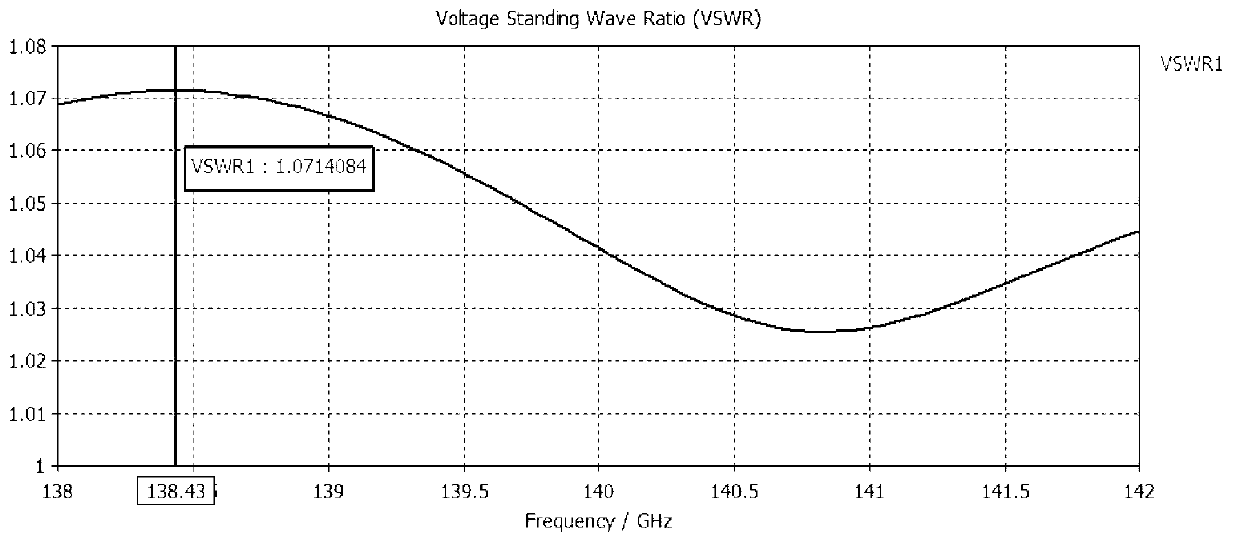

[0019] The coupler of this embodiment has been simulated (the system transmission parameters are the same as those in Embodiment 1), image 3 The upper part shows the coupling coefficient (S31) curve, ranging from -72.14dB (138.05GHz) to -70.86dB (139.78GHz); the lower part shows the isolation (S41) curve, ranging from -89.18dB (138.05 GHz)—-105.08dB (140.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com