A method of manufacturing portunid crab bait

A production method and technology of swimming crab, which are applied in the application, animal feed, animal feed and other directions, can solve the problems of short shelf life on board, troubled fishermen, and high cost of bait fish, and achieve loose internal tissue, better palatability, and pollution prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

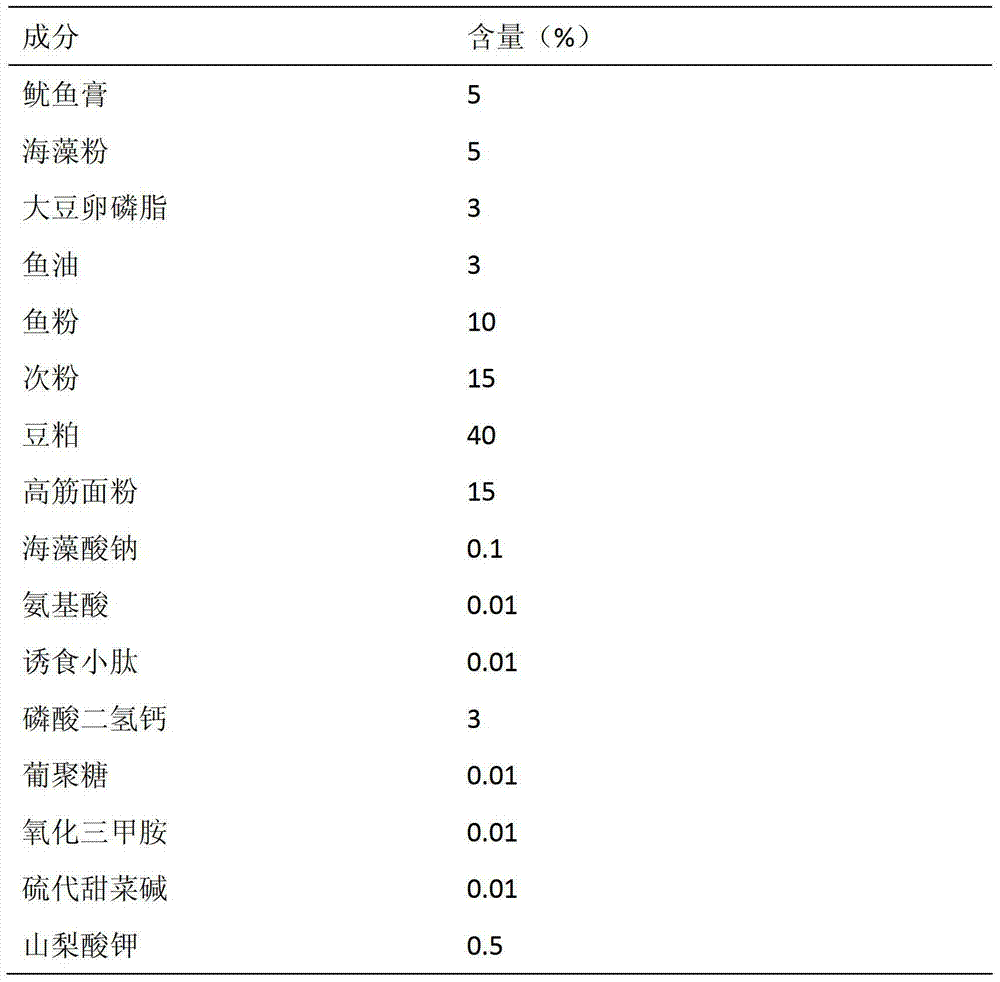

[0017] In weight percentage, the raw material composition situation of a kind of portunus bait of the present embodiment is as shown in table 3:

[0018] Table 1

[0019]

[0020] The sum of the above components is 100%. The sources of each substance are as follows:

[0021] Squid paste: Feed grade seafood, Zhejiang Xingye Group Oil Feed Factory

[0022] Soy lecithin: food grade Shanghai Emmons Chemical Technology Co., Ltd.

[0023] Seaweed powder: feed grade Shanghai Yinong Biochemical Technology Co., Ltd.

[0024] Fish oil: Feed grade Zhejiang Xingye Group Oil Feed Factory

[0025] Soybean meal: soybean meal protein > 43, fermented high protein oil soybean meal Shouguang Longyuan Feed Co., Ltd.

[0026] Sodium alginate: feed grade Shandong Yantai Kaipu Biological Engineering Co., Ltd.

[0027] Fishmeal: Feed grade Shandong Binzhou Honglu Feed Co., Ltd.

[0028] Secondary flour: Jiangsu Sanniu Flour Co., Ltd.

[0029] High-gluten flour: Hebei Yongfa Noodle Industry...

Embodiment 2

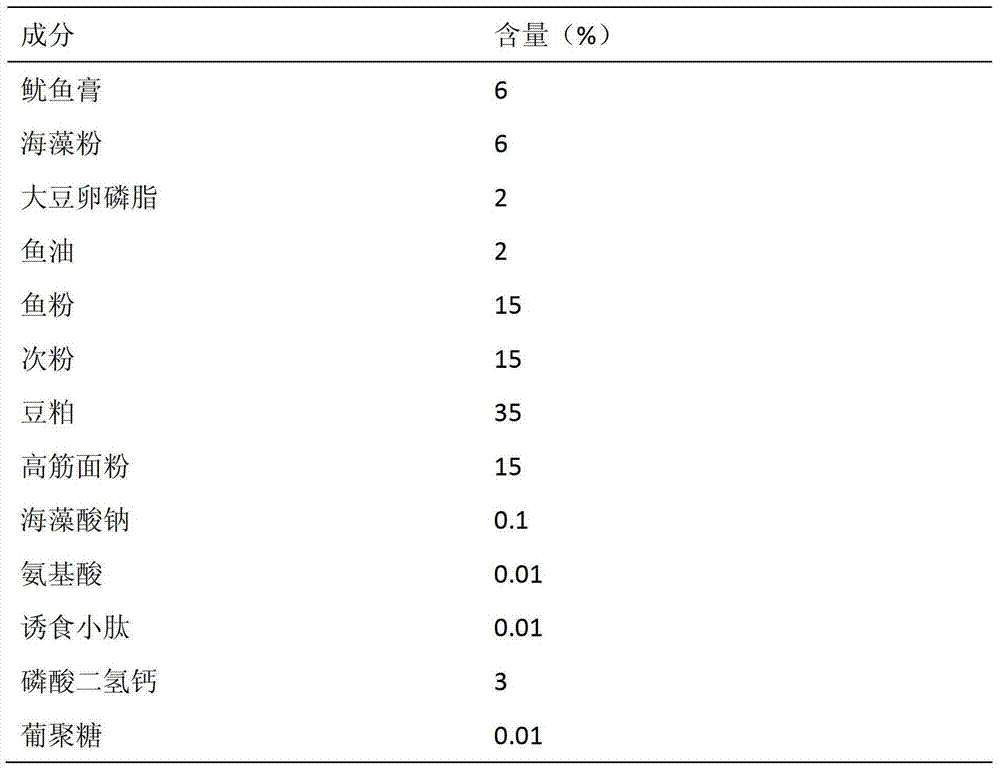

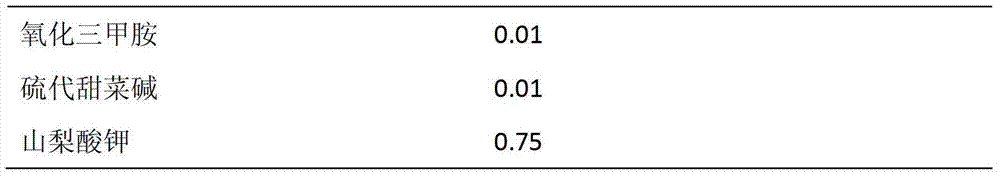

[0052] In weight percentage, the raw material composition situation of a kind of portunus bait of the present embodiment is as shown in table 3:

[0053] table 3

[0054]

[0055]

[0056] The sum of the above components is 100%.

[0057] Squid paste: Feed grade seafood, Zhejiang Xingye Group Oil Feed Factory

[0058] Soy lecithin: food grade Shanghai Emmons Chemical Technology Co., Ltd.

[0059] Seaweed powder: feed grade Shanghai Yinong Biochemical Technology Co., Ltd.

[0060] Fish oil: Feed grade Zhejiang Xingye Group Oil Feed Factory

[0061] Soybean meal: soybean meal protein > 43, fermented high protein oil soybean meal Shouguang Longyuan Feed Co., Ltd.

[0062] Sodium alginate: feed grade Shandong Yantai Kaipu Biological Engineering Co., Ltd.

[0063] Fishmeal: Feed grade Shandong Binzhou Honglu Feed Co., Ltd.

[0064] Secondary flour: Jiangsu Sanniu Flour Co., Ltd.

[0065] High-gluten flour: Hebei Yongfa Noodle Industry Group Co., Ltd.

[0066] Amino ac...

Embodiment 3

[0078] In weight percentage, the raw material composition situation of a kind of portunus bait of the present embodiment is as shown in table 5:

[0079] table 5

[0080]

[0081] The sum of the above components is 100%.

[0082] Squid paste: Feed grade seafood, Zhejiang Xingye Group Oil Feed Factory

[0083] Soy lecithin: food grade Shanghai Emmons Chemical Technology Co., Ltd.

[0084] Seaweed powder: feed grade Shanghai Yinong Biochemical Technology Co., Ltd.

[0085] Fish oil: Feed grade Zhejiang Xingye Group Oil Feed Factory

[0086] Soybean meal: soybean meal protein > 43, fermented high protein oil soybean meal Shouguang Longyuan Feed Co., Ltd.

[0087] Sodium alginate: feed grade Shandong Yantai Kaipu Biological Engineering Co., Ltd.

[0088] Fishmeal: Feed grade Shandong Binzhou Honglu Feed Co., Ltd.

[0089] Secondary flour: Jiangsu Sanniu Flour Co., Ltd.

[0090] High-gluten flour: Hebei Yongfa Noodle Industry Group Co., Ltd.

[0091] Amino acid: animal f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com