Acetylene dimerization nonaqueous phase catalyst as well as preparation method and application thereof

A catalyst and non-aqueous phase technology, which is applied in the preparation of acetylene dimerization catalysts and in the field of catalyst preparation. It can solve the problems of low vinyl acetylene conversion rate and low selectivity of acetylene, and achieve less time, low cost and high selectivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

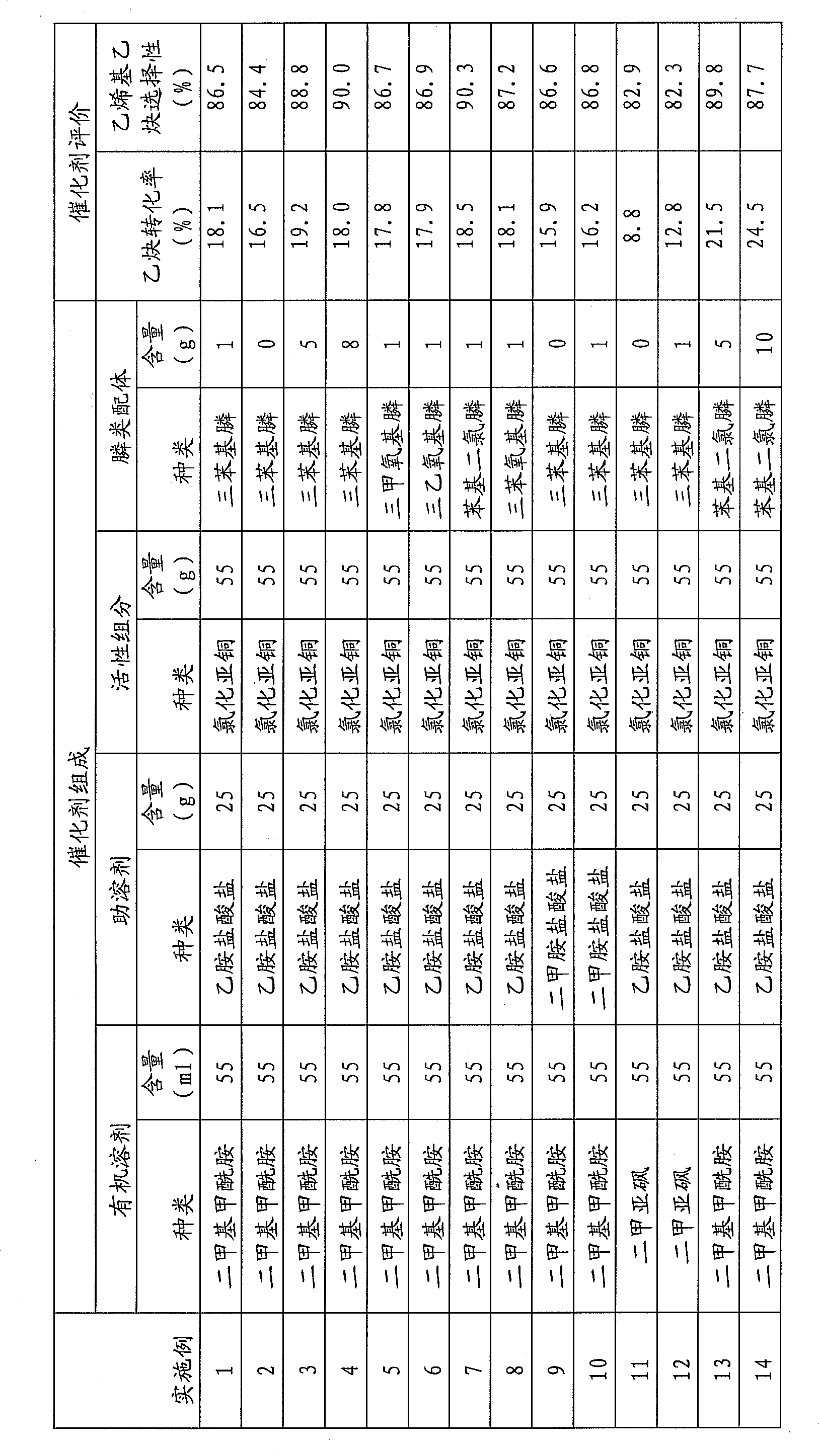

[0028] Embodiment 1: Preparation of acetylene dimerization non-aqueous phase catalyst

[0029] Measure 55ml of dimethylformamide and pour it into a two-necked flask, add 25g of ethylamine hydrochloride to it after heating to 60°C, place the two-necked flask in a constant temperature water bath on a magnetic stirrer (constant temperature 60°C) , and put a magnetic stirring rotor into it, and the rotating speed is maintained at 1000-1300 rpm. After the ethylamine hydrochloride was completely dissolved, nitrogen was introduced into one mouth of the two-neck flask, and 55 g of CuCl and 1 g of triphenylphosphine were sequentially added into the other mouth. The above mixture was stirred for 30 min to obtain the desired non-aqueous phase catalyst.

Embodiment 2-14

[0031] According to the raw material composition in the following table, the preparation method of Example 1 was repeated to prepare the acetylene dimerization non-aqueous catalysts of Examples 2-14.

[0032] Catalyst Effect Evaluation

[0033] The catalyst prepared by embodiment 1-14 is evaluated according to the following methods:

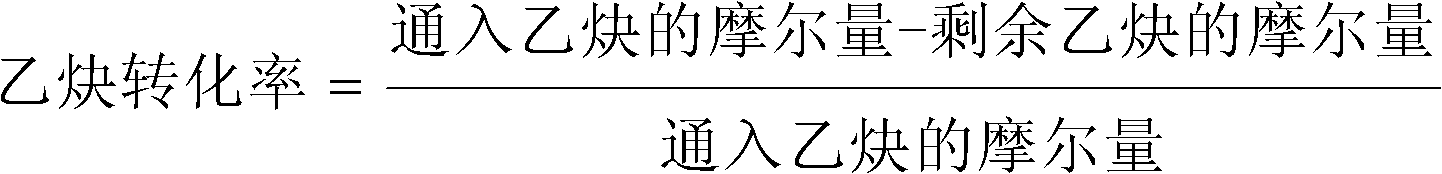

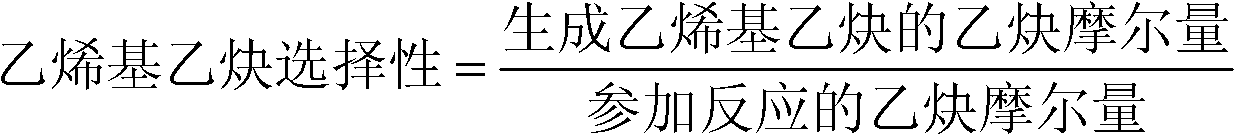

[0034] In the bubbling bed device, the catalysts prepared in Examples 1-14 were used to carry out acetylene dimerization reaction, and then the gas obtained by the reaction was collected, wherein the reaction conditions were: reaction temperature 65 ° C, reaction pressure was normal pressure, acetylene space velocity was 200h -1 (ratio of acetylene volume flow to catalyst volume). Then, Agilent 1790 type gas chromatography was used to analyze the composition of the collected gas samples, so as to obtain the amounts of acetylene and vinyl acetylene in the collected gas samples. Among them, the chromatographic column used is a 30m×0.53mm glass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com