Device and method for elutriation and separation of sludge and treatment and reuse of sewage in through channel

A ditch sludge and sewage treatment technology, applied in water/sludge/sewage treatment, centrifuged water/sewage treatment, sludge treatment, etc., can solve the need for regular maintenance of circulation and lifting pump systems, sewage treatment devices Problems such as large footprint and low separation efficiency achieve the effect of saving running time, reducing floor space and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

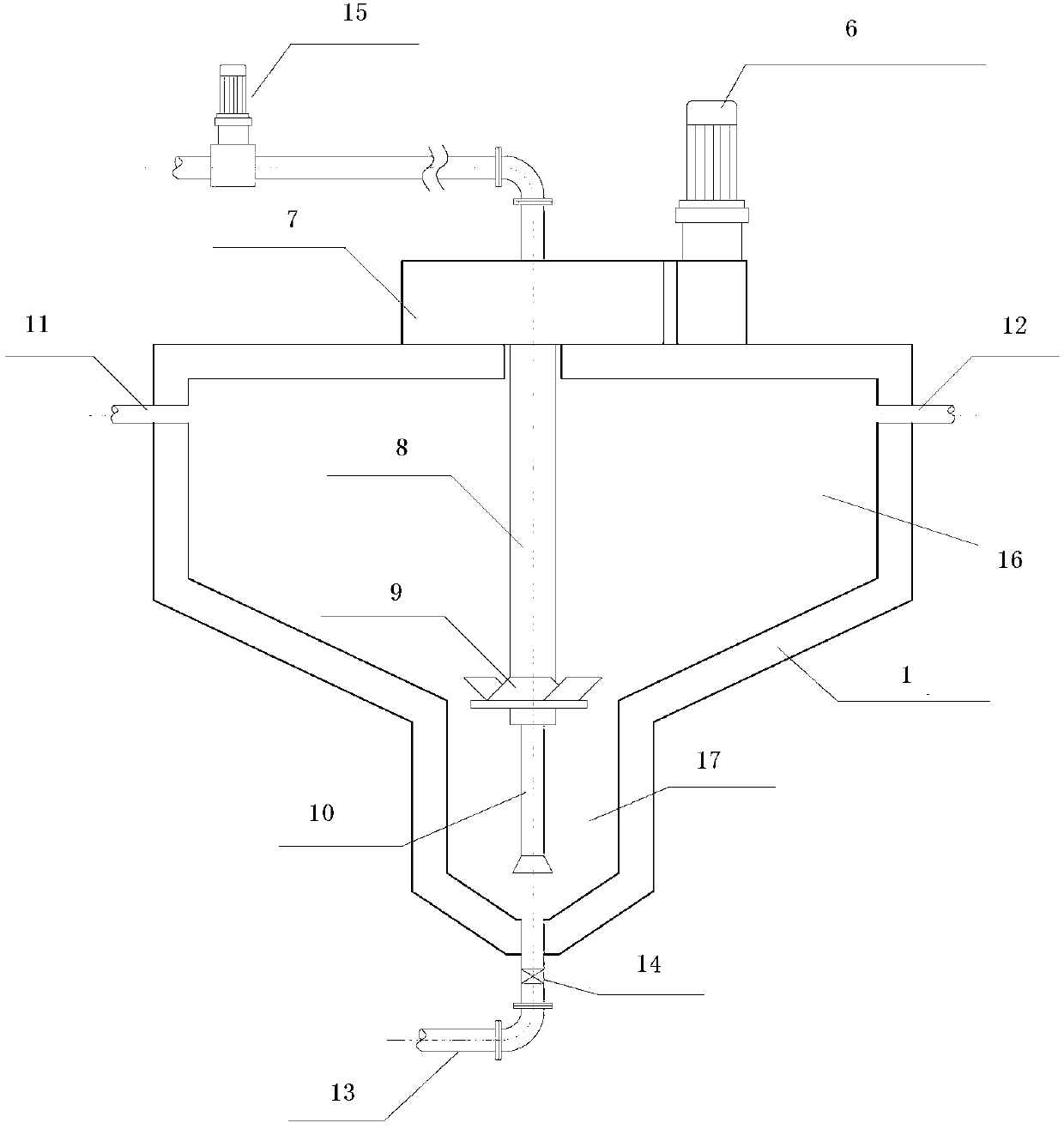

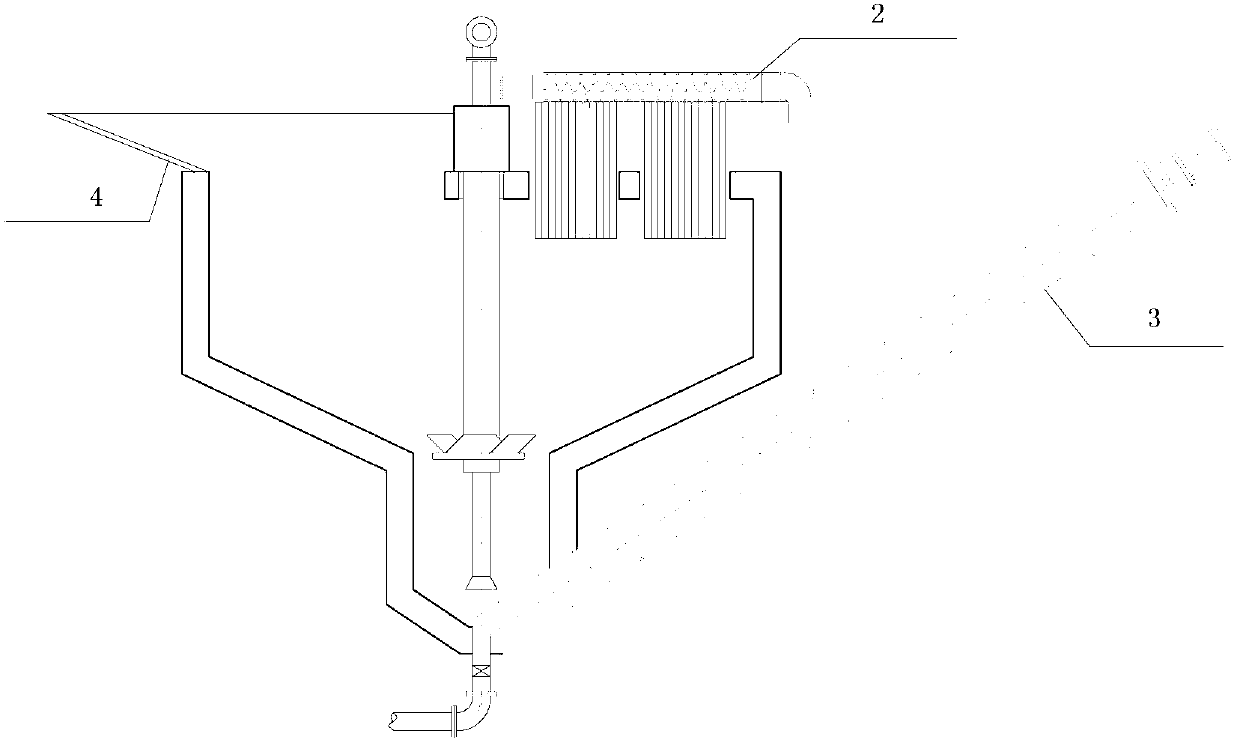

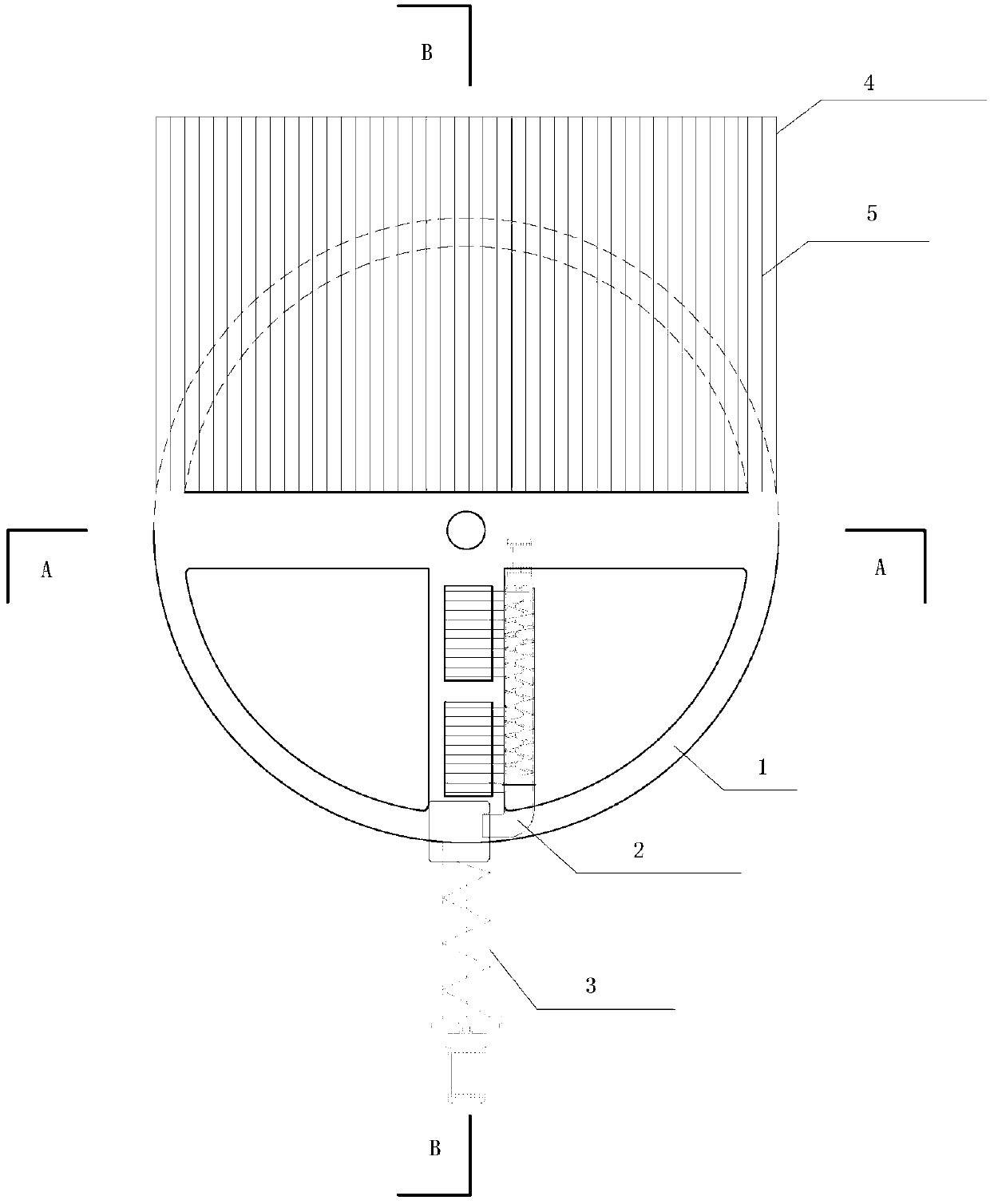

[0012] Such as Figure 2~4 As shown, an integrated device for elutriation and separation of trench sludge and sewage treatment and reuse includes an elutriation separation tank 1, which is characterized in that the elutriation separation tank 1 is composed of a conical elutriation separation chamber 16 (the taper is 2: 1) Composed of conical grit chamber 17 (taper 2:1~1:1), elutriation separation tank 1 is provided with steel platform grid 5, and steel platform grid 5 is provided with a sludge receiving chute 4, The grid spacing of the steel platform grid 5 is 10cm~20cm. The upper part of the elutriation and separation tank 1 is equipped with a slag extraction machine 2, and the upper part of the elutriation separation tank 1 is equipped with a motor 6 with a gearbox. The hollow drive shaft 8 is driven by the transmission gear box 7, and the turntable and the blades 9 are driven to rotate. A dredging pipe 10 is installed in the grit chamber 17. The dredged pipe 10 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com