Method for preparing 1-chlorine-2-(dichloro(benzene)methyl) benzene solution

A technology of benzene solution and methyl), which is applied in the field of preparation of 1-chloro-2-methyl)benzene solution, achieves the effects of good color and appearance, reduced by-product content and excellent swelling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

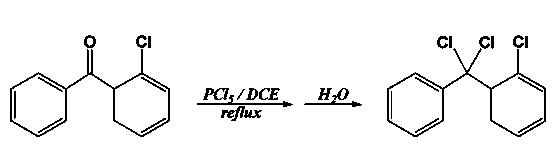

Image

Examples

preparation example Construction

[0014] The preparation method of 1-chloro-2-(dichloro(phenyl)methyl)benzene solution of the present invention comprises the steps:

[0015] 1. Put o-chlorobenzophenone and dichloroethane in a mass ratio of 1:4~8, put them into the reaction kettle, raise the temperature to 55~65°C, and stir until completely dissolved.

[0016] The dosage ratio of dichloroethane and o-chlorobenzophenone is 4~8:1 according to the mass ratio; if the ratio is too low, it is not enough to quickly dissolve o-chlorobenzophenone; if the ratio is too high, unnecessary solvent waste will be caused . The dissolution temperature is controlled at 55~65°C, which is slightly higher than the melting point of o-chlorobenzophenone, but too high a temperature (such as above 65°C) will lead to a more violent instantaneous reaction when the subsequent phosphorus pentachloride is fed, which is difficult to operate unfavorable.

[0017] 2. Put phosphorus pentachloride solid powder with a molar ratio of 1.05~1.2:1 t...

Embodiment 1

[0027] Preparation of 1-chloro-2-(dichloro(phenyl)methyl)benzene solution : At room temperature, inject 1600 milliliters (about 2000 grams) of dichloroethane into a 3-liter three-neck flask, add 400 grams of o-chlorobenzophenone (purity 99%, 1.828 moles), stir, and heat up to 62 ° C in a water bath. After stirring for 20 minutes, the solids were completely dissolved. Slowly add 420 grams of phosphorus pentachloride solid powder (purity 99%, 1.996 mol), slowly heat up to 87°C within 30 minutes, reflux for 12 hours, then gradually cool the reactant to 20°C with a cold water bath. Slowly put the reactants in the three-neck flask into 10 liters of ice / water (mass ratio 3:7) mixture, stir and hydrolyze for 2 hours, the temperature first slowly rises to 57°C, and then falls naturally; stand for 15 minutes, use Separate the lower organic phase with a separatory funnel. Stir and wash the organic phase with tap water 7 times, add 10 liters of tap water each time, stir and wash f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com