Polyamide wood-plastic composite material and preparation method thereof

A wood-plastic composite material and polyamide technology, applied in the field of polyamide wood-plastic composite material and its preparation, can solve the problems of the development of wood-plastic composite material, low decomposition temperature of wood filler, high processing temperature of nylon 6, etc. The effect of good performance, environmental protection and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh raw materials according to the following parts by weight:

[0038] Nylon 6 is 100 parts of reclaimed polycaprolactam,

[0039] 30 parts wood filler,

[0040] Inorganic filler (talcum powder, particle size is 500-2000 mesh.) 5 parts,

[0041] Processing aids (MgBr 2 ) 2 copies,

[0042] Compatibilizer 0 parts,

[0043] 0.5 parts of coupling agent (KH-550),

[0044] Antioxidant (antioxidant 1098) 0.2 part,

[0045] Lubricant (PE wax) 0.3 parts.

[0046] Carry out batching according to above-mentioned weight portion, nylon 6, compatibilizer, processing aid MgBr 2 1. Antioxidant 1098 is put into a high-speed mixer and mixed at a high speed. After mixing for 3 minutes, it is fed into the hopper of a twin-screw extruder;

[0047] Then put the wood filler, inorganic filler talc powder, coupling agent KH-550, and lubricant PE wax into the high-speed mixer and mix at high speed. After mixing for 4 minutes, add the twin-screw extruder from the side feeding port; con...

Embodiment 2-5

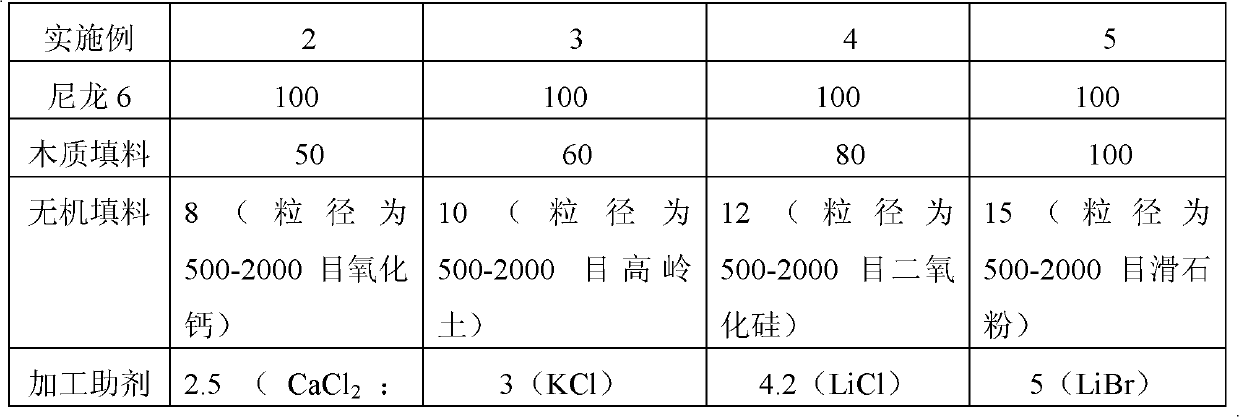

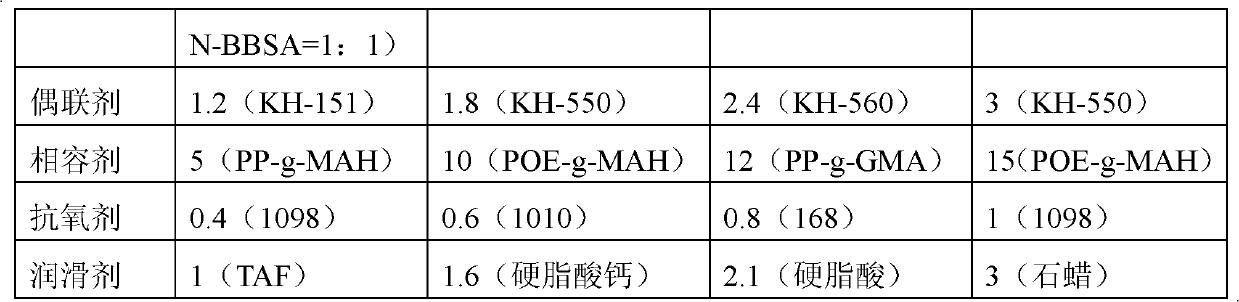

[0049] In Examples 2-5, the components and amounts of raw materials are shown in Table 1 (by weight), and the preparation method is the same as in Example 1.

[0050] The nylon 6 used below is a new polycaprolactam material.

[0051] Table 1

[0052]

[0053]

[0054] The mechanical properties of the polyamide wood-plastic composite materials prepared in Examples 2-5 are shown in Table 2.

[0055] Table 2

[0056] Example

[0057] It can be seen from Table 2 that the present invention overcomes the contradiction between the high processing temperature of nylon 6 and the low decomposition temperature of wood filler, fully utilizes the characteristics of excellent performance and good processing fluidity of nylon 6, and the obtained wood-plastic composite material has better strength, The advantages of high fluidity and better injection molding can be widely used as wood substitute materials in various fields of social life. It is conducive to energy saving, e...

Embodiment 6

[0059] Put 100 parts of recycled polycaprolactam, 8 parts of compatibilizer PP-g-MAH, 1 part of processing aid N-E-O / PTSA, and 0.5 parts of antioxidant 1098 into a high-speed mixer and mix at a high speed. After mixing for 3 minutes, feed to Twin-screw extruder hopper;

[0060]Then put 70 parts of wood filler, 9 parts of talc powder with a particle size of 500-2000 mesh, and 2 parts of coupling agent KH-550 into a high-speed mixer for high-speed mixing. Exit the machine: control the temperature of each zone, from the feed port to the die head of the extruder, the temperature is 210 ° C, 230 ° C, 240 ° C, 190 ° C, 220 ° C, the main engine speed is 50Hz, extruded and granulated by the twin-screw extruder That's it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com