Preparation method of fish scale gelatin of bighead carp

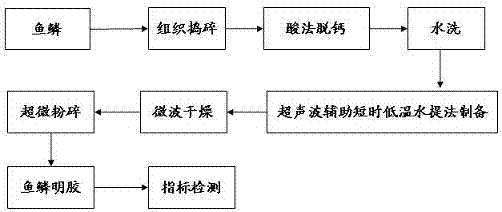

A fish scale gelatin and fish scale technology, which is applied in the field of animal gelatin preparation, can solve the problems of poor heat resistance, long extraction cycle, and low fish gelatin yield, and achieve high gel melting temperature, high yield, and shorten the preparation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Decalcification of fish scales: (1) Removal of fish scales: Use a tissue grinder to treat fish scales for 5 minutes to remove fish scales; (2) Acid decalcification: Use hydrochloric acid to decalcify fish scales. The liquid ratio is 1:20, the concentration of hydrochloric acid is 0.5 mol / L, and the decalcification time is 1 h; (3) Cleaning: remove the decalcification solution, and wash the scales until neutral.

[0019] 2. Preheating of the ultrasonic equipment: set the parameters of the ultrasonic equipment, set the power of the ultrasonic equipment to 200 W, set the temperature to 60 °C, start the equipment heating device, and preheat for 30-40 minutes to reach the required temperature for the reaction.

[0020] 3. Efficient preparation of fish scale gelatin: place a beaker containing decalcified bighead carp scales and distilled water in the ultrasonic reactor, start the ultrasonic generating device, and terminate the reaction after 1 hour to obtain high yield, hig...

Embodiment 2

[0025] 1. Decalcification of fish scales: (1) Removal of fish scales: Use a tissue grinder to treat fish scales for 5 minutes to remove fish scales; (2) Acid decalcification: Use hydrochloric acid to decalcify fish scales. The liquid ratio is 1:20, the concentration of hydrochloric acid is 0.5 mol / L, and the decalcification time is 1 h; (3) Cleaning: remove the decalcification solution, and wash the scales until neutral.

[0026] 2. Preheating of the ultrasonic equipment: set the parameters of the ultrasonic equipment, set the power of the ultrasonic equipment to 200 W, set the temperature to 60 °C, start the equipment heating device, and preheat for 30-40 minutes to reach the required temperature for the reaction.

[0027] 3. Efficient preparation of fish scale gelatin: place a beaker containing decalcified bighead carp scales and distilled water in the ultrasonic reactor, start the ultrasonic generating device, and stop the reaction after 3 hours to obtain high yield and high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com