Surfactant for fracturing fluid and preparation method and fracturing fluid thereof

A technology of surfactant and fracturing fluid, which is applied in the field of fracturing fluid, can solve the inconvenience of fracturing fluid and other problems, and achieve the effects of convenient liquid preparation, no pre-allocation process, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

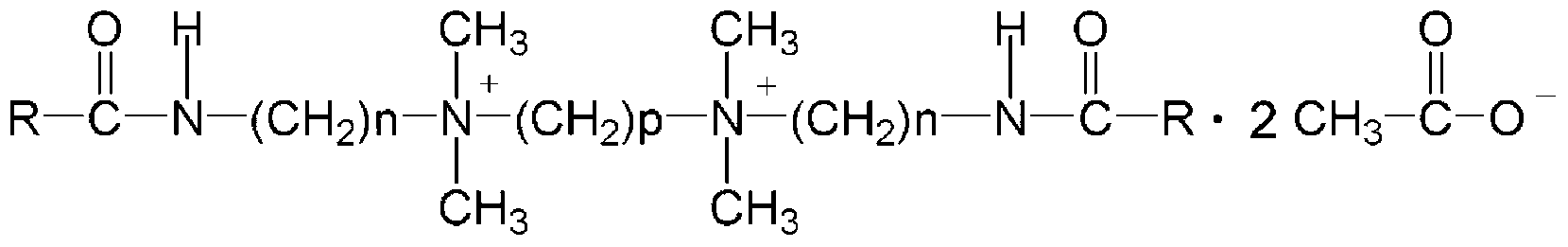

Method used

Image

Examples

Embodiment 1

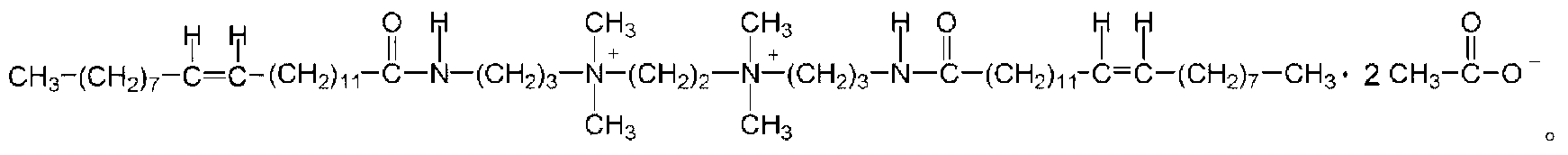

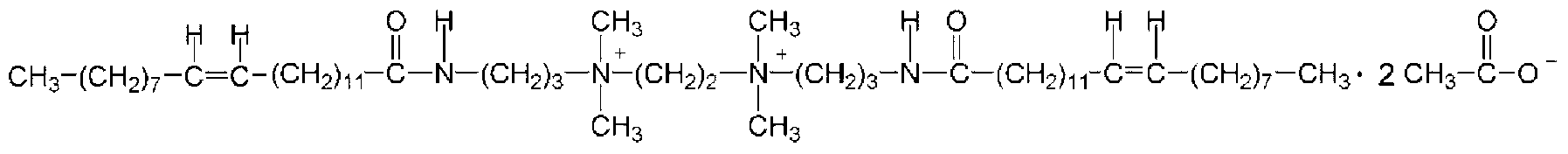

[0033] In a 250mL three-necked grinding flask with a condensing reflux tube, add sinapinic acid and N,N-dimethylpropylamine to carry out amidation condensation reaction, use potassium hydroxide as a catalyst, stir and reflux, react for 7 hours, and the reaction temperature is At 150°C, the intermediate product tertiary amine was obtained.

[0034] Add dichloroethane to the above-mentioned intermediate product tertiary amine to carry out chain splicing reaction, stir and reflux, react for 3 hours, and the reaction temperature is 125° C. to obtain the intermediate product spliced chain tertiary amine.

[0035] Add the prepared intermediate tertiary chain amine and an appropriate amount of isopropanol into a three-necked flask, add the pre-neutralized sodium chloroacetate solution in portions, stir and reflux, and react at 75°C for 5 hours to obtain a yellow to brown viscous Liquid, the mass percentage of active ingredients is 49%-51%. The structural formula of the active ingr...

Embodiment 2

[0039] Fracturing fluid, composed of the following components by mass percentage:

[0040] Surfactant 1.0%

[0041] Potassium chloride 12.0%

[0042] Water 87%, wherein surfactant is the tensio-active agent that embodiment one gains.

[0043] The fracturing fluid obtained in this example was subjected to a performance test at 80°C, and the results are shown in Table 1:

[0044] Table 1 Example 2 obtained fracturing fluid performance test

[0045] serial number

Embodiment 3

[0047] Fracturing fluid, composed of the following components by mass percentage:

[0048] Surfactant 2.0%

[0049] Potassium chloride 10.0%

[0050] Water 88%, wherein surfactant is the surfactant obtained in embodiment one.

[0051] The fracturing fluid obtained in this example was subjected to a performance test at 100°C, and the results are shown in Table 2:

[0052] Table 2 Performance test of fracturing fluid obtained in Example 3

[0053] serial number

[0054] 6

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com