Method and device for measuring low-frequency and small-range vibration signals

A vibration signal and measuring device technology, applied in measuring devices, vibration testing, electrical devices, etc., can solve the problems of frequency compensation circuit failure, reducing vibration signal measurement accuracy, mechanical fatigue, etc., to avoid shortening the service life, overcome the measurement Effects of Signal Failure Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

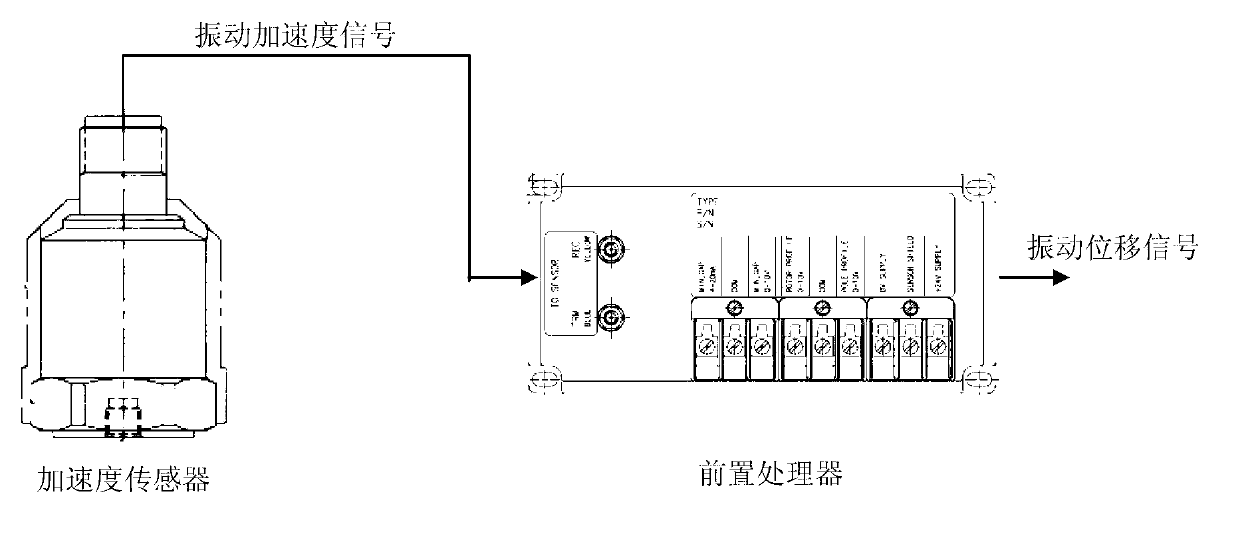

[0033] The embodiment of the present invention applies the acceleration sensor to the measurement field of low-frequency and small-amplitude vibration signals for the first time. In the actual acceleration sensor, there is a big problem, that is, the output signal of the acceleration sensor contains a large number of noise signals, which originate from circuit noise, transmission noise and noise caused by piezoelectric crystal installation and manufacturing process. The noise is manifested as the smaller the frequency, the larger the noise. For commonly used accelerometers, the noise below 10Hz is between 5ug√Hz and 10ug√Hz, or even higher.

[0034] The magnification of the integral circuit for integral amplification of the acceleration signal has an inverse relationship with the frequency. The smaller the frequency, the greater the discharge multiple of the signal. When the frequency approaches 0Hz, the magnification is close to infinity. This is the characteristic of the int...

Embodiment 2

[0072] In this example, the above Figure 4 The second-level analog integral module and subsequent modules in the pre-processor shown are digitally completed by single-chip microcomputer. The specific structure of the above-mentioned pre-processor provided by this embodiment is as follows: Figure 10 As shown, the following modules are included:

[0073] The DC-blocking low-impedance module 101 is used to connect the low-pass module, which is a high-pass filter module, and the high-pass cut-off frequency is designed at 0.5Hz. It is used to receive the vibration acceleration signal output by the acceleration sensor, and perform DC blocking and high-pass filtering processing on the vibration acceleration signal through the RC (resistance-capacitance) circuit, remove the DC signal component in the received vibration acceleration signal, and filter out low frequency Based on the vibration acceleration signal of the set low frequency threshold, the vibration acceleration signal p...

Embodiment 3

[0085] The processing flow of the processing method of a low-frequency, small-amplitude vibration signal measurement method provided by this embodiment is as follows: Figure 11 As shown, the following processing steps are included:

[0086] Step 11, setting the acceleration sensor on the measured object, after the acceleration sensor detects the low-frequency, small-amplitude vibration signal sent by the measured object, convert the low-frequency, small-amplitude vibration signal into a vibration acceleration signal, and convert the vibration Acceleration signal output, the resonant frequency of the acceleration sensor is greater than the maximum effective vibration frequency of the vibration signal sent by the measured object.

[0087] The vibration signal sent by the above-mentioned measured object is a low-frequency, small-amplitude signal. In the embodiment of the present invention, the maximum effective vibration frequency of the vibration signal sent by the above-mentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com