Photoresist stripping fluid composition and application thereof

A technology of stripping liquid and composition, which is applied in the direction of photosensitive material processing, etc., can solve the problems of easy corrosion and easy corrosion of metal lines, etc., and achieve the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The positive-type photosensitive resin composition of novolak resin system is placed in a coating machine (model is MS-A150; purchased from Shin Kong Trading, Taiwan), and coated on a 2 inch × 2 inch surface by spin coating. On the glass substrate containing the aluminum metal film, dry it under reduced pressure at 100mmHg for 5 seconds, then pre-bake it in an oven at 110°C for 1.5 minutes to form a pre-baked coating film with a film thickness of 3.5 μm. The pre-baked coating film is placed between the specified masks (mask), and the stepping machine (Nikon1755G7A) is used at 20mJ / cm 2 After irradiating with a certain amount of light, develop with 0.84% potassium hydroxide aqueous solution at 23°C for 1 minute, remove the coating film on the exposed part of the substrate, and then wash it with pure water. Then, post-bake at 170° C. for 15 minutes in an oven to form a photoresist line film with a film thickness of 3.0 μm on the glass substrate containing the aluminum m...

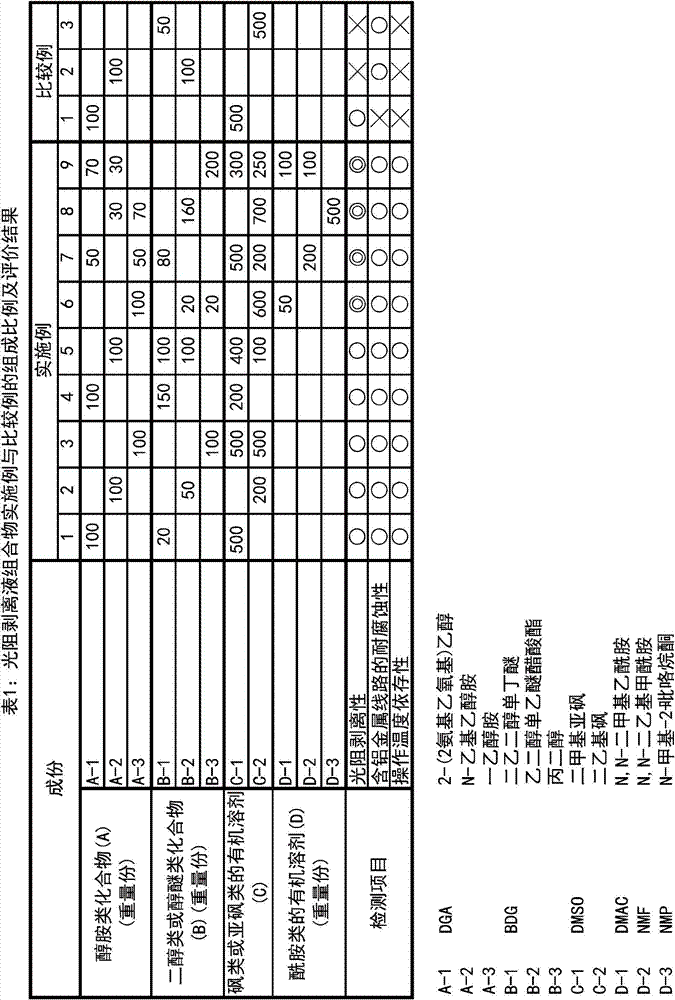

Embodiment 2 to 9 and comparative example 1 to 3

[0053] Examples 2 to 9 and Comparative Examples 1 to 3 use the same operating method as in Example 1, the difference is that the type and mixing amount of the photoresist stripper composition are changed, and the detailed information and follow-up evaluation results are set out in the table 1.

[0054] 1. Photoresist stripping property:

[0055] The above-mentioned glass substrate with aluminum-containing metal circuit was used to observe the situation of photoresist residue by SEM, and evaluated according to the following criteria:

[0056] ◎: No photoresist residue

[0057] ○: A little photoresist remains

[0058] ╳: A large number of photoresist residues

[0059] 2. Corrosion resistance of aluminum-containing metal lines:

[0060] The aforementioned glass substrates with aluminum-containing metal circuits were observed by SEM to observe the surface of the aluminum-containing metal circuits, and were evaluated according to the following criteria:

[0061] ○: There is no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com