System and method for treating abnormal exhaust gas in metal sulfide ore smelting

A flue gas treatment system and flue gas treatment technology, applied in the metallurgical field, can solve problems such as being unable to be used for acid production, unable to better meet process requirements, etc., and achieve the effects of reducing energy consumption, low environmental pollution, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

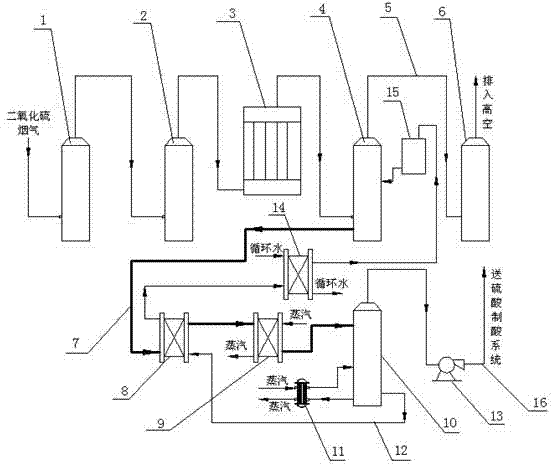

[0021] like figure 1 As shown, a system for treating abnormal flue gas in the smelting of metal sulfide ores includes a turbulence tower 1, a washing tower 2, an electric demister 3 and a primary absorption tower 4 connected in sequence, and also includes a first plate exchanging Heater 8, second plate heat exchanger 9 and desorption tower 10, the top of the primary absorption tower 4 communicates with the secondary absorption tower 6 through the first exhaust pipe 5, and the bottom connects with the first through the rich liquid delivery pipe 7 in turn. The plate heat exchanger 8, the second plate heat exchanger 9 and the desorption tower 10 are connected, the bottom of the desorption tower 10 is connected with a reboiler 11 and a lean liquid delivery pipe 12, and the top is connected with the fan 13 through a second exhaust pipe 16. Connection, the other end of the lean liquid delivery pipe 12 is connected with a liquid storage tank 15 through the first plate heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com