Trimethylamine malodorous gas treatment method

A technology of malodorous gas and treatment method, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of up-to-standard discharge of tail gas treatment, and achieve the effects of strong adaptability, high treatment efficiency, and wide application range of gas sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

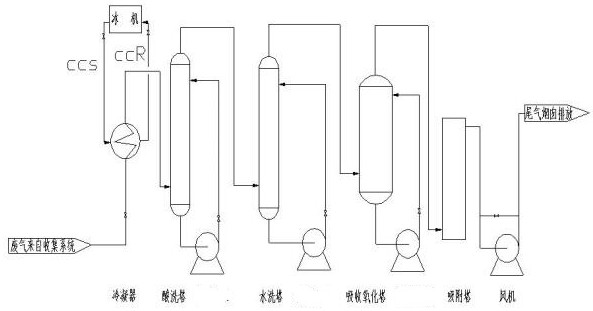

Embodiment 1

[0029] A company that produces tetramethylammonium hydroxide collected trimethylamine-containing tail gas from synthesis kettles and stills. The main components are benzyl chloride, methanol, ethyl chloride, and trimethylamine. The incoming cooling medium is heat-exchanged to 0°C and enters the pickling tower, using 0.1mol / L HCl aqueous solution to wash and absorb the gas under the action of the acid circulation pump, and the absorbed gas enters the water washing tower with a concentration of 1% by mass The plant extract aqueous solution further washes and absorbs the gas, and the gas from the water washing tower is further introduced into the absorption oxidation tower, and the H 2 o 2 : Fe 2+ The oxidizing aqueous solution with a molar ratio of 4 and a pH value of 3 is in countercurrent contact with the bottom-up gas under the action of the solution pump, and the malodorous gas components are absorbed and oxidized, and the tail gas from the absorption oxidation tower is int...

Embodiment 2

[0031] A company that produces parylene collected trimethylamine-containing tail gas from synthesis kettles, ring closure kettles, distillation kettles, etc. The main components are benzyl chloride and trimethylamine. Heat to 3°C, enter the pickling tower, use 0.3mol / L H 2 SO 4The aqueous solution washes and absorbs the gas under the action of the acid circulation pump, and the absorbed gas enters the water washing tower, and the gas is further washed and absorbed by the plant extract aqueous solution with a concentration of 0.5% by mass, and the gas exiting the water washing tower is further introduced into the absorption oxidation tower , using H 2 o 2 : Fe 2+ The oxidizing aqueous solution with a molar ratio of 5 and a pH value of 4 is in countercurrent contact with the bottom-up gas under the action of the solution pump, and the malodorous gas components are absorbed and oxidized, and the tail gas from the absorption oxidation tower is introduced into the adsorption tow...

Embodiment 3

[0033] In a certain enterprise, the tail gas containing trimethylamine collected from the workshop, the main components are trimethylamine, methanol, propane, under the action of the fan, it exchanges heat with the cooling medium from the ice machine to 5°C, enters the pickling tower, and uses 0.4mol / L HNO 3 The aqueous solution washes and absorbs the gas under the action of the acid circulation pump, and the absorbed gas enters the water washing tower, and the gas is further washed and absorbed by the plant extract aqueous solution with a mass percent concentration of 4%, and the gas exiting the water washing tower is further introduced into the absorption oxidation tower , using H 2 o 2 : Fe 2+ The oxidizing aqueous solution with a molar ratio of 6 and a pH value of 5 is in countercurrent contact with the bottom-up gas under the action of the solution pump, and the malodorous gas components are absorbed and oxidized, and the tail gas from the absorption oxidation tower is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com