Method for rapid preparation of polymer multilayer film

A polymer, multi-layer film technology, used in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of unsuitable industrial production, long preparation process, high substrate requirements, and achieve excellent chemical stability, Improved preparation speed and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

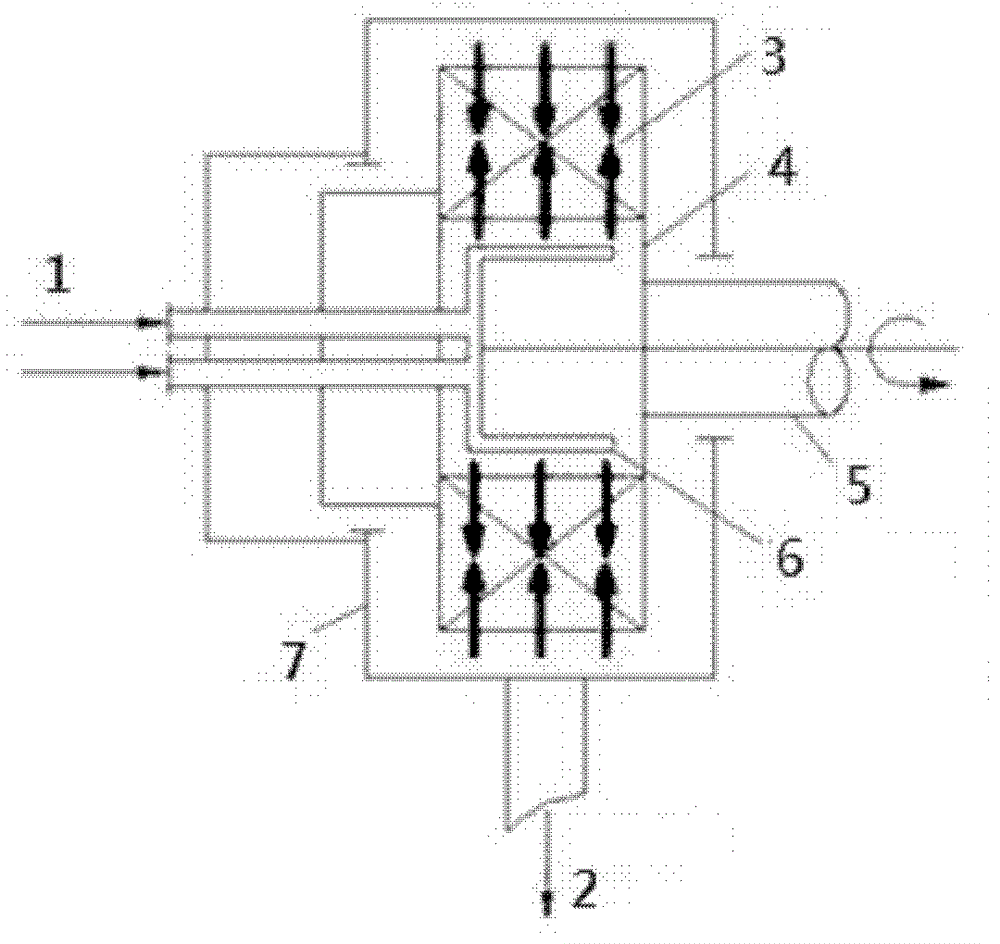

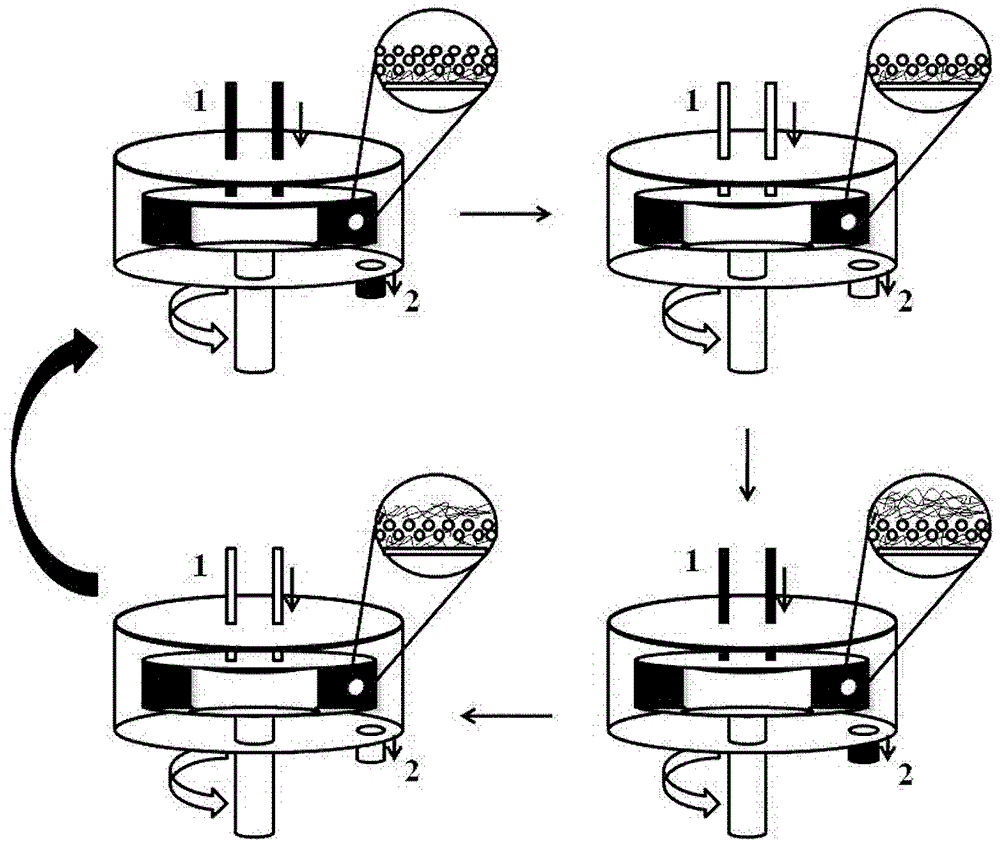

Method used

Image

Examples

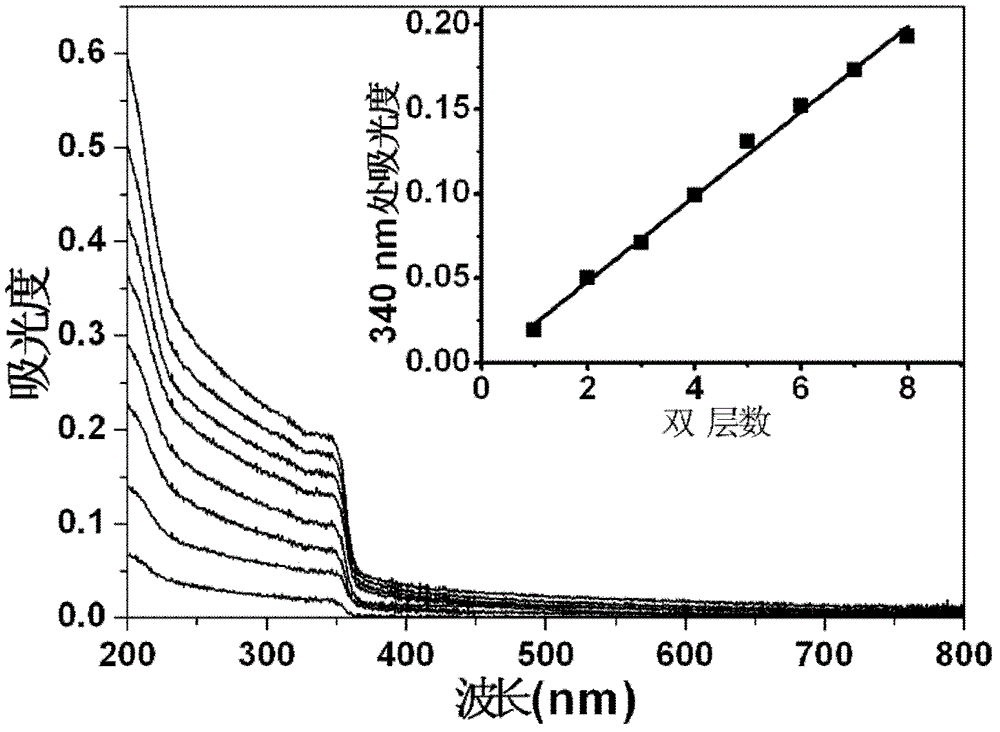

Embodiment 1

[0038] 1. Soak the quartz piece in a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide (the volume ratio of concentrated sulfuric acid and hydrogen peroxide is 7:3) and clean until no bubbles are generated, then clean the quartz piece with deionized water , and then blow dry with nitrogen;

[0039] 2. Prepare the required PEI ethanol solution and nano-zinc oxide ethanol solution: dissolve and dilute PEI and nano-zinc oxide ethanol solution with a mass fraction of 30% in absolute ethanol respectively, and the concentration of the prepared solution is 0.1mg / ml;

[0040] 3. Adjust the flow rate of the feed constant flow pump at 42ml / min, and the speed of the supergravity machine at 2400rpm;

[0041] 4. Soak the cleaned quartz slice in 0.1mg / ml PEI ethanol solution for 30min, wash it with absolute ethanol, and then dry it with nitrogen;

[0042] 5. Insert the quartz piece soaked in PEI ethanol solution into the card slot of the rotor of the ultra-gravity ...

Embodiment 2

[0047] 1. Soak the quartz piece in a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide (the volume ratio of concentrated sulfuric acid and hydrogen peroxide is 7:3) and clean until no bubbles are generated, then clean the quartz piece with deionized water , and then blow dry with nitrogen;

[0048] 2. Prepare the required PEI ethanol solution and nano-zinc oxide ethanol solution: dissolve and dilute PEI and nano-zinc oxide ethanol solution with a mass fraction of 30% in absolute ethanol respectively, and the concentration of the prepared solution is 0.1mg / ml;

[0049] 3. Adjust the flow rate of the feed constant flow pump at 42ml / min;

[0050] 4. Soak the cleaned quartz slice in 0.1mg / ml PEI ethanol solution for 30min, wash it with absolute ethanol, and then dry it with nitrogen;

[0051] 5. The speed of supergravity is adjusted at 3000rpm. Insert the quartz slice soaked in PEI ethanol solution into the card slot of the rotor of the ultra-gravity mac...

Embodiment 3

[0055] 1. Soak the silicon wafer in a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide (the volume ratio of concentrated sulfuric acid and hydrogen peroxide is 7:3) and clean until no bubbles are generated, then clean the silicon wafer with deionized water , and then blow dry with nitrogen;

[0056] 2. Prepare the required PEI ethanol solution and nano-zinc oxide ethanol solution: dissolve and dilute PEI and nano-zinc oxide ethanol solution with a mass fraction of 30% in absolute ethanol respectively, and the concentration of the prepared solution is 1mg / ml;

[0057] 3. Adjust the flow rate of the feed constant flow pump at 42ml / min, and the speed of the supergravity machine at 2400rpm;

[0058] 4. Soak the cleaned silicon wafer in 1mg / ml PEI ethanol solution for 30min, wash it with absolute ethanol, and then dry it with nitrogen;

[0059] 5. Insert the silicon chip soaked in PEI ethanol solution into the card slot of the rotor of the ultra-gravity m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com