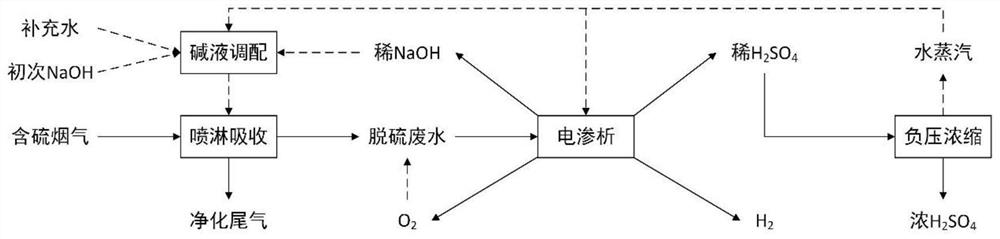

Flue gas desulfurization and sulfur-containing waste liquid recycling coupling process

A technology of resource utilization and flue gas, applied in the direction of gaseous effluent wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high operating cost, low product utilization rate, complex desulfurization process, etc., to achieve Reduce process operating costs, realize resource utilization, and have strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] SO in flue gas containing sulfur 2 Effect of Concentration on Treatment Process

[0067] A coupling process of flue gas desulfurization and sulfur-containing waste liquid recycling described in this embodiment specifically includes the following steps:

[0068] (1) Set up five groups of comparative experiments numbered 1, 2, 3, 4, and 5 respectively, and compare the SO in the sulfur-containing flue gas of groups 1-5 2The concentrations were set to 1%, 3%, 5%, 10%, and 15% respectively; each group of sulfur-containing flue gas was injected into their respective spray towers, and the dilute NaOH solution produced by electrolysis was adjusted by concentration (the mole fraction was 1mol / L ) is returned to the lye tank and injected into the spray tower, and the sulfur-containing flue gas reacts with the dilute NaOH solution to generate sulfur-containing waste liquid;

[0069] (2) O produced by electrolysis 2 Pre-oxidize the sulfur-containing waste liquid; the pre-oxidize...

Embodiment 2

[0077] Effect of different mole fractions of NaOH solution on the treatment process

[0078] A coupling process of flue gas desulfurization and sulfur-containing waste liquid recycling described in this embodiment specifically includes the following steps:

[0079] (1) Set up five groups of comparative experiments numbered 6, 7, 8, 9, and 10 respectively, inject 6-10 groups of sulfur-containing flue gas into their respective spray towers, and adjust the molar fraction of dilute NaOH solution produced by electrolysis to 0.1 mol / L, 0.5mol / L, 1mol / L, 1.5mol / L, 2mol / L, and then return to the lye tank and inject into the spray tower, the sulfur-containing flue gas reacts with the dilute NaOH solution to generate sulfur-containing waste liquid;

[0080] (2) O produced by electrolysis 2 Pre-oxidize the sulfur-containing waste liquid; the pre-oxidized sulfur-containing waste liquid is injected into the electrolytic dialysis cell and converted into dilute H 2 SO 4 and dilute NaOH so...

Embodiment 3

[0088] Influence of Vacuum Degree on Treatment Process

[0089] A coupling process of flue gas desulfurization and sulfur-containing waste liquid recycling described in this embodiment specifically includes the following steps:

[0090] (1) Set up five groups of comparative experiments numbered 11, 12, 13, 14, and 15 respectively, inject sulfur-containing flue gas of groups 11-15 into respective spray towers, and dilute NaOH solutions produced by electrolysis in each group are adjusted by concentration ( The mole fraction is 1mol / L) back to the lye tank and injected into the spray tower, the sulfur-containing flue gas reacts with the dilute NaOH solution to generate sulfur-containing waste liquid;

[0091] (2) O produced by electrolysis 2 Pre-oxidize the sulfur-containing waste liquid; the pre-oxidized sulfur-containing waste liquid is injected into the electrolytic dialysis cell and converted into dilute H 2 SO 4 and dilute NaOH solution, while producing electrolysis produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com