Natural fiber and polylactic acid fiber blended fibreboard and preparation method thereof

A polylactic acid fiber and natural fiber technology, applied in the field of polymer materials and composite materials, can solve problems such as difficulty in reducing weight, achieve excellent mechanical properties, good environmental benefits, and avoid pollution and harm to human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

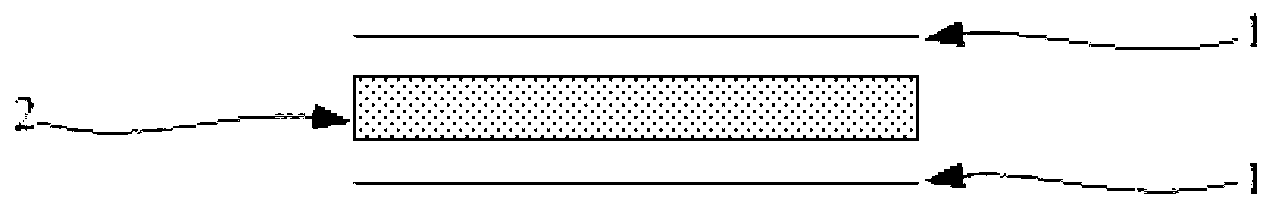

Method used

Image

Examples

Embodiment 1

[0028] Mix ramie staple fiber (fiber length 50mm, diameter 60μm, cross-sectional shape is round) and polylactic acid short fiber (fiber length 50mm / denier 1.8D / cross-sectional shape) according to the mass ratio of 4:6. , through carding, laying and needle-punching to make blended fiber felt, the specification is 5000g / m 2 ; Then add a layer with a density of 20g / m on the upper and lower surfaces of the blended fiber mat 2 The pure polylactic acid film is used as the surface layer; after the billet is assembled, it is placed in a 180°C vacuum oven to preheat for 10 minutes, and then quickly moved to the forming mold, and then it is air-pressed at 0.6MPa and then cooled and shaped at 40°C.

[0029] According to the standards GB / T1447-2005, GB / T1449-2005 and ASTM D256-2010, perform performance tests respectively. After testing, the prepared natural fiber and polylactic acid fiber blended fiberboard has a tensile strength of 78.82MPa, a bending strength of 69.98MPa, and an impact...

Embodiment 2

[0031] Mix jute short fibers (fiber length 80mm, diameter 25μm, polygonal cross-section) and polylactic acid short fibers (fiber length 80mm / denier 1D / cross-section polygonal) in a mass ratio of 1:1, after carding, Laying netting and needle punching to make blended fiber felt with a specification of 1000g / m 2 ; Then add a layer with a density of 500g / m on the upper and lower surfaces of the blended fiber mat 2 The polylactic acid non-woven fabric is used as the surface layer; after the billet is assembled, it is placed in a vacuum oven at 150°C for preheating for 20 minutes, and then quickly moved to the forming mold.

[0032] According to the standards GB / T1447-2005, GB / T1449-2005 and ASTM D256-2010, perform performance tests respectively. After testing, the prepared natural fiber and polylactic acid fiber blended fiberboard has a tensile strength of 36.05MPa, a bending strength of 24.61MPa, and an impact strength of 104.94J / m.

Embodiment 3

[0034] Mix flax staple fiber (fiber length 20mm, diameter 17μm, cross-sectional shape is polygonal) and polylactic acid short fiber (fiber length 20mm / denier 4D / cross-sectional shape is Y-shaped) according to the mass ratio 6:4, after carding, Laying and needle-punching to make blended fiber felt with a specification of 1900g / m 2 ; Add a layer of PBAT-modified polylactic acid-based film on the upper and lower surfaces of the blended fiber felt (area density 50g / m 2 ) as the surface layer; after forming the billet, put it in a vacuum oven at 175°C for 15 minutes to preheat, then quickly move it to the forming mold, and form it under air pressure at 0.4MPa, then cool and set it at 35°C.

[0035] According to the standards GB / T1447-2005, GB / T1449-2005 and ASTM D256-2010, perform performance tests respectively. After testing, the tensile strength of the prepared natural fiber and polylactic acid fiber blended fiberboard is 51.31MPa, the bending strength is 34.58MPa, and the impac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com