Hospital wastewater treatment process equipment and hospital wastewater treatment method

A technology for wastewater treatment and process equipment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , high concentration of suspended solids, to achieve good disinfection effect, compact equipment, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

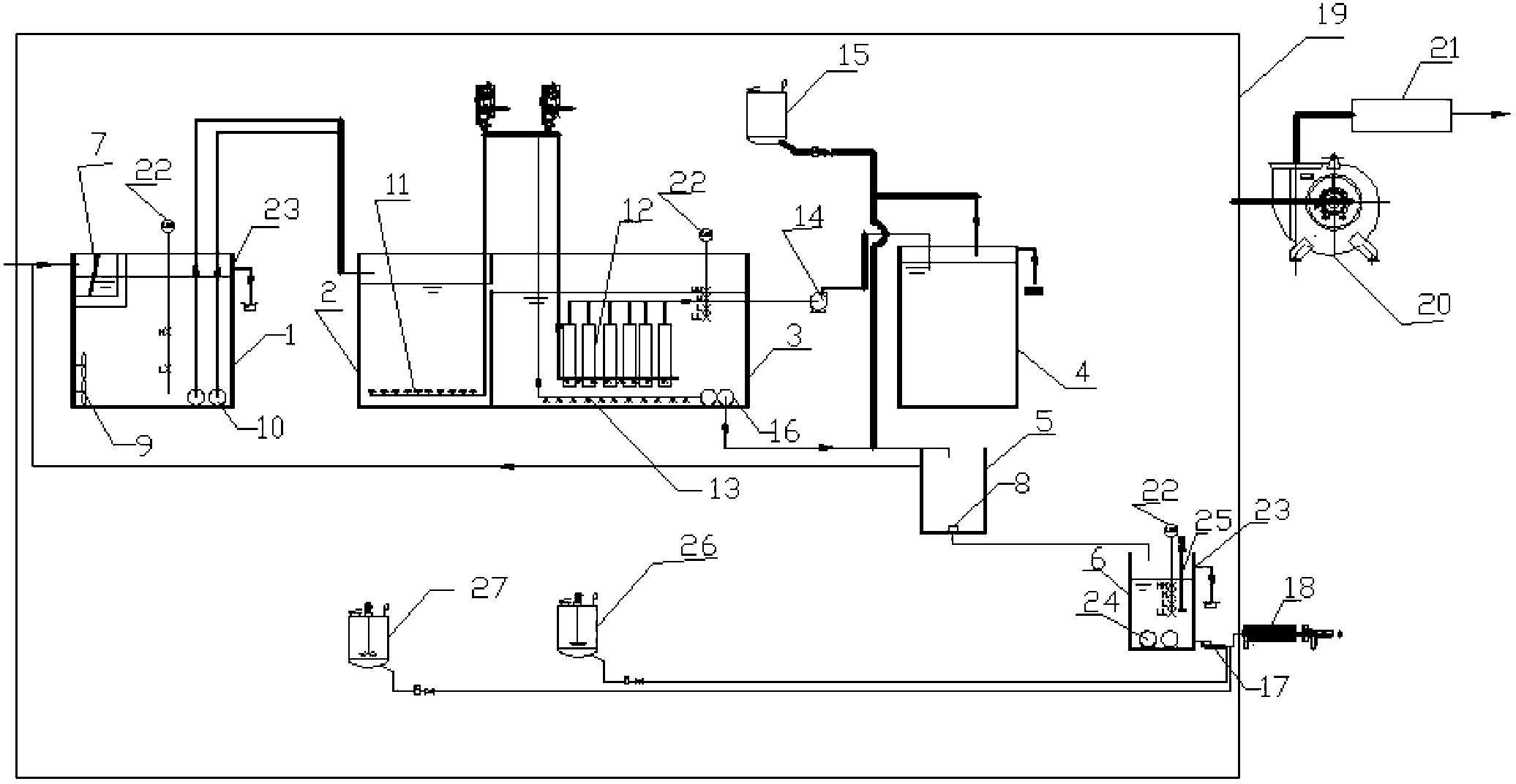

[0035] like figure 1As shown, the present invention provides a kind of hospital waste water treatment process equipment, comprises adjustment tank 1, contact oxidation tank 2, membrane bioreactor 3, water production tank 4, sludge sedimentation tank 5, mud storage tank 6, tail gas treatment device; The upper end in the regulating pool 1 is provided with a grid well 7, and the regulating pool 1 is provided with at least one submersible mixer 9 and at least one sewage lifting pump 10; The water inlet is connected, the water outlet of the contact oxidation tank 2 is connected with the water inlet of the membrane bioreactor 3, the contact oxidation tank 2 is provided with a microporous aerator 11, and the The contact oxidation tank 2 is provided with a semi-soft filler; the membrane bioreactor 3 is provided with a submerged microfiltration membrane module 12, and the material of the submerged microfiltration membrane module 12 is polyvinylidene fluoride, and the membrane bioreacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com