Sewage treatment plant sludge sintered brick and preparation method thereof

A technology for sewage treatment plants and sintered bricks, applied in the field of sintered bricks, can solve the problems of large content of organic matter in sludge, low utilization efficiency of sludge, and low plasticity of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

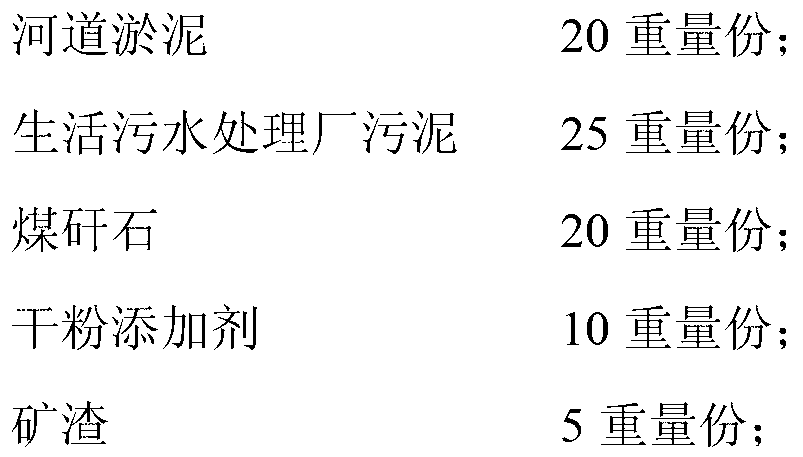

[0026] Prepare a sewage treatment plant sludge sintered brick, the ingredients (dry) are as follows:

[0027]

[0028] Preparation process steps:

[0029] (1) The river sludge is dehydrated into viscous sludge with a water content of 20wt%; at the same time, the sludge from domestic sewage treatment plants is dehydrated into a water content of 25wt%;

[0030] (2) Grinding coal gangue, dry powder additives and slag to a particle size of 0.1-3mm;

[0031] (3) Mix the above-mentioned processed materials according to the proportion;

[0032] (4) Then aging for 5 days until the total water content is 13wt%;

[0033] (5) Semi-hard extrusion into bricks, the molding pressure is controlled at 2.1-2.7MPa; drying, tunnel kiln roasting, heating up steadily, the heating rate is controlled at 2-4°C / min, after 7 hours of tunnel kiln firing at 900-950°C, Made out of the kiln. Peeling, hoarseness, and cracking are considered unqualified, and the yield rate is 98%; the prepared sintered...

Embodiment 2

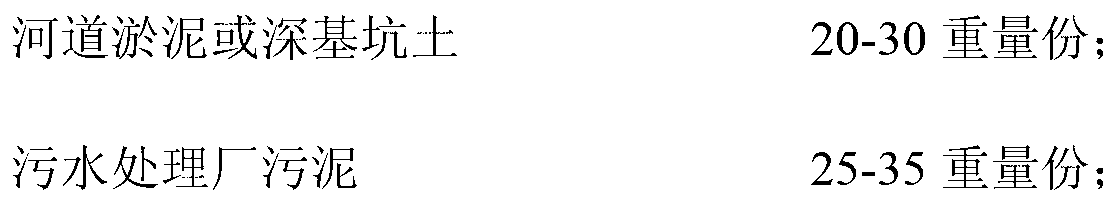

[0037] Prepare a sewage treatment plant sludge sintered brick, the ingredients (dry) are as follows:

[0038]

[0039] Preparation process steps:

[0040] (1) The river sludge is dehydrated into viscous sludge with a water content of 30wt%; at the same time, the sludge from domestic sewage treatment plants is dehydrated into a water content of 35wt%;

[0041] (2) Grinding coal gangue, dry powder additives and slag to a particle size of 0.1-3mm;

[0042] (3) Mix the above-mentioned processed materials according to the proportion;

[0043] (4) Then aging for 7 days until the total water content is 18wt%;

[0044] (5) Semi-hard extrusion into bricks, the molding pressure is controlled at 2.1-2.7MPa; drying, tunnel kiln roasting, heating up steadily, the heating rate is controlled at 2-4°C / min, 900-950°C tunnel kiln roasting for 9 hours, It is made out of the kiln; peeling, mute, and cracking are considered unqualified, and the yield rate is 99%; the prepared sintered brick ...

Embodiment 3

[0048] Prepare a sewage treatment plant sludge sintered brick, the ingredients (dry) are as follows:

[0049]

[0050] Preparation process steps:

[0051] (1) The river sludge is dehydrated into viscous sludge with a water content of 22wt%; at the same time, the sludge from domestic sewage treatment plants is dehydrated into a water content of 28wt%;

[0052] (2) Grinding coal cinders, dry powder additives and slag to a particle size of 0.1-3mm;

[0053] (3) Mix the above-mentioned processed materials according to the proportion;

[0054] (4) Then aging for 6 days until the total water content is 15wt%;

[0055] (5) Semi-hard extrusion into bricks, the molding pressure is controlled at 2.1-2.7MPa; drying, tunnel kiln roasting, heating up steadily, the heating rate is controlled at 2-4°C / min, and after 8 hours of tunnel kiln firing at 900-950°C, Made out of the kiln. Peeling, hoarseness, and cracking are considered unqualified, and the yield rate is 99%; the prepared sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com