Multi-element urea-based composite fertilizer and production method thereof

A technology of urea-based compound fertilizer and production method, which is applied in the field of multi-element urea-based compound fertilizer and production, which can solve the problems of poor product appearance, agglomeration, and low particle strength, and achieve round appearance, large surface area, and low drying energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

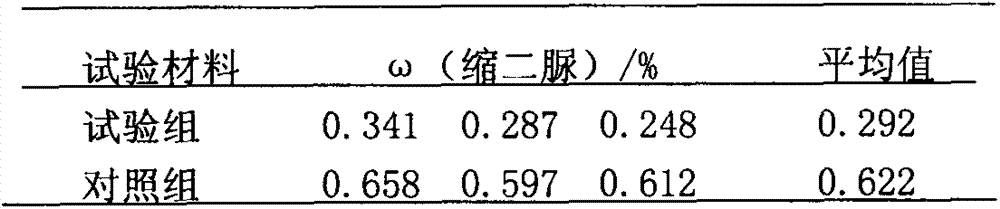

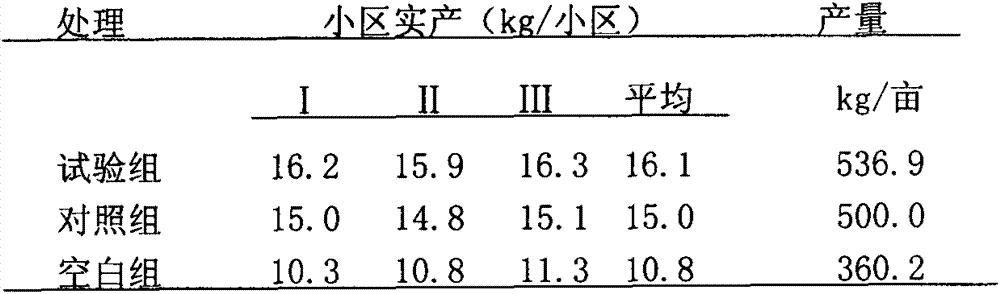

Examples

Embodiment 1

[0063] (1) Preparation of urea sulfate: 150 kg of urea (containing N46%), 73 kg of concentrated sulfuric acid (98%), and 7 kg of water were added to the preparation tank with agitator at the same time. During the addition, pay close attention to the preparation Changes in the tank temperature, the reaction temperature is controlled at 60-80°C by cooling the circulating water, and after about 40 minutes, the reaction is completed and a clear urea sulfate solution is generated.

[0064] (2) Spraying: the urea sulfate solution prepared above is uniformly mixed with 60.5 kg of concentrated sulfuric acid (98%) in a mixer and then sprayed into the granulator through a nozzle.

[0065] (3) Granulation: There are 160 kg of powdered diammonium phosphate, 160 kg of calcium magnesium phosphate fertilizer, 210 kg of potassium chloride, 31 kg of bentonite, and 31 kg of pine needle powder in the granulator. 43 kg of liquid ammonia is sprayed into the pellet machine. After 5 minutes of gran...

Embodiment 2

[0069] (1) Preparation of urea sulfate: 320 kg of urea (containing N46%), 150 kg of concentrated sulfuric acid (98%), and 15 kg of water were added to the preparation tank with agitator at the same time. During the addition, pay close attention to the preparation Changes in the tank temperature, the reaction temperature is controlled at 60-80°C by cooling circulating water, and after about 30 minutes, the reaction is completed and a clear urea sulfate solution is generated.

[0070] (2) Spraying: the urea sulfate solution prepared above is sprayed into the granulator through the nozzle after uniformly mixing with 121 kilograms of concentrated sulfuric acid (98%) in a mixer.

[0071] (3) Granulation: There are 325 kg of powdered diammonium phosphate, 325 kg of calcium magnesium phosphate fertilizer, 430 kg of potassium chloride, 65 kg of bentonite, and 65 kg of pine needle powder in the granulator. 89 kg of liquid ammonia is sprayed into the granulator. After 8 minutes of gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com