Process for recovering and purifying neptunium from waste liquor discharged from 2AW+2DW in Purex flow

A process and process technology, applied in the field of nuclear fuel reprocessing, can solve problems such as unsuitable for purification and recovery, unfavorable material liquid follow-up treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

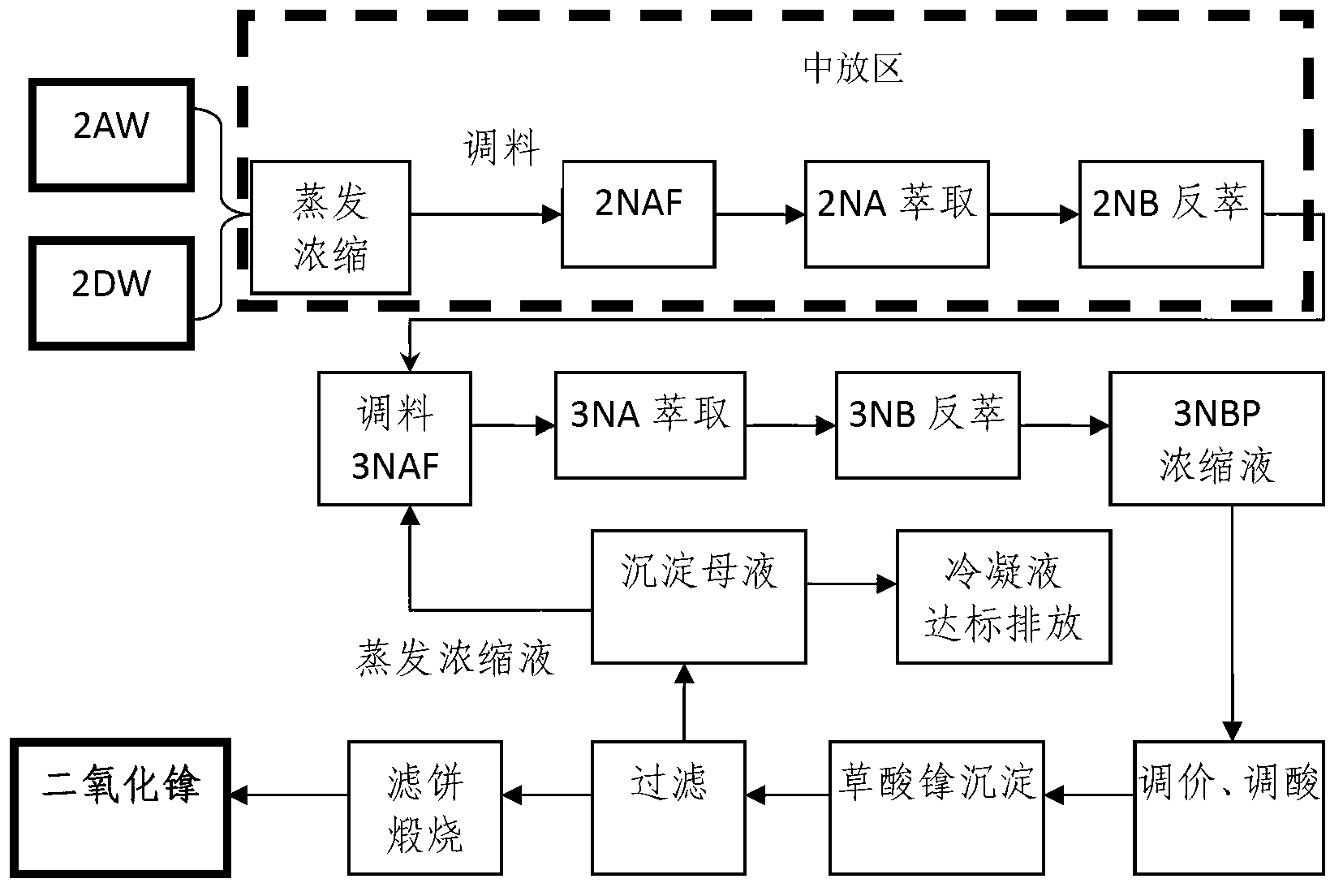

[0029] The experimental bench is installed in the glove box, and the neptunium in the plutonium extraction tank raffinate 2AW and the uranium extraction tank raffinate 2DW feed liquid is recovered and purified, and the operation steps are as follows:

[0030] (1) After the plutonium extraction tank raffinate 2AW and the uranium extraction tank raffinate 2DW are evaporated and concentrated, sodium metavanadate is used as the oxidant seasoning, and 5mol / L HNO 3 Adjust the acidity to obtain 2NAF, the feed liquid to be purified, in which 2NAF contains Np, U, Pu and fragment elements, and Np mainly exists in the form of Np(Ⅵ);

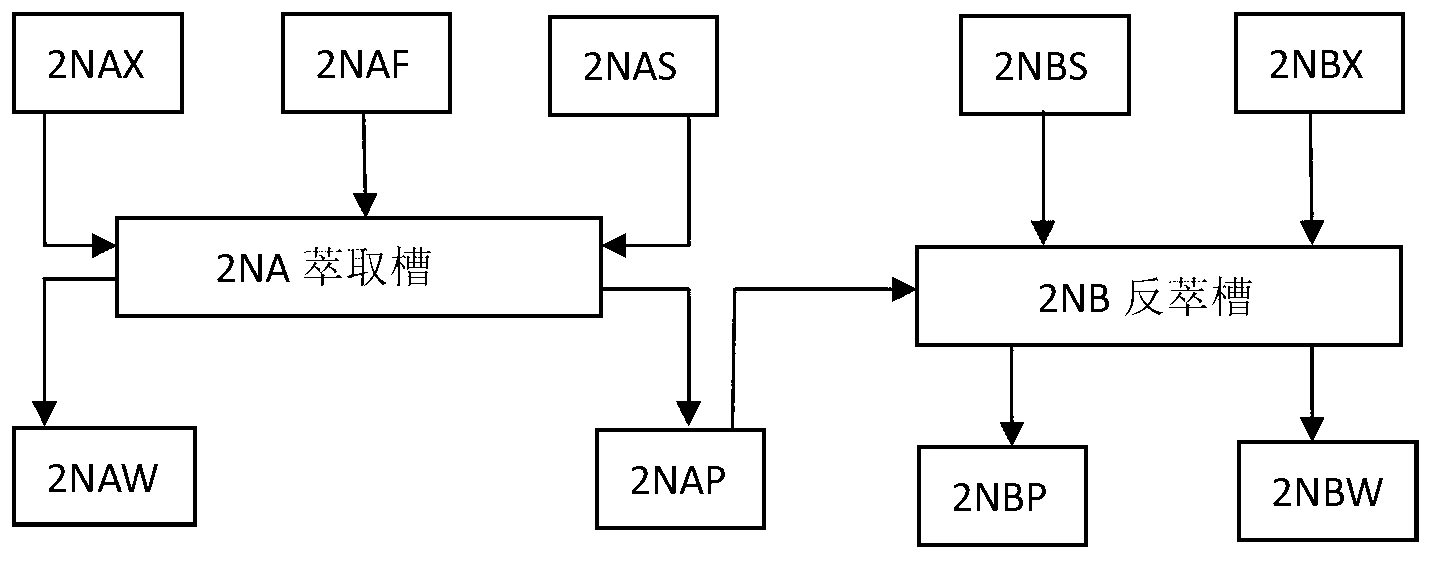

[0031] (2) Introduce 2NAF into neptunium extraction tank 2NA, and introduce 30% TBP-kerosene (volume fraction) into 2NA as extractant 2NAX, 3mol / L HNO 3 As a detergent 2NAS, in which U, Np, and Pu are co-extracted into the organic phase 2NAP, and the split elements enter into the aqueous phase 2NAW, and the flow ratio of 2NAX:2NAF:2NAS is 1:3:1.

[0032] (...

Embodiment 2

[0041] The operation steps and method are the same as in Example 1, except that the parameters such as seasoning concentration and reducing agent concentration change, as shown in the following table:

[0042] Table 1 parameter list

[0043]

Embodiment 3

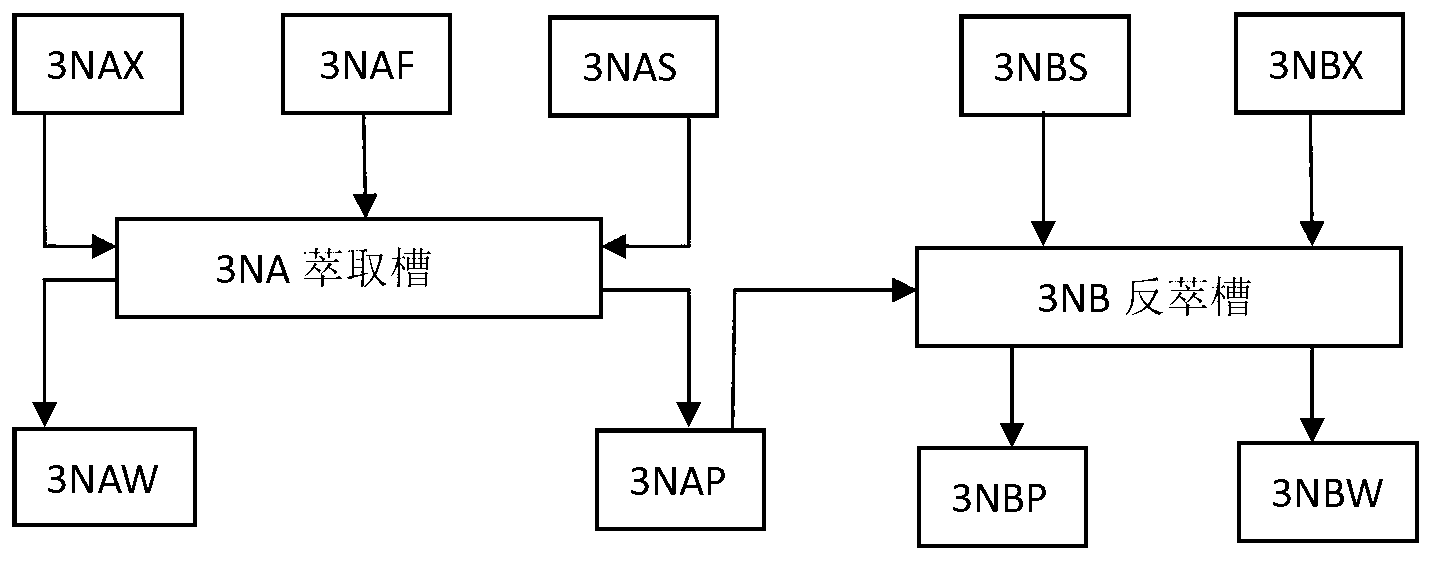

[0045] The operation steps and methods are the same as those in Example 1, except that the seasoning parameters and oxalic acid concentration in step (4) of the second purification process are specifically 3NBP with 5mol / L HNO 3 , 0.6 mol / L hydrazine seasoning, add 1.0 mol / L oxalic acid and make the oxalic acid excess 0.1 mol / L, carry out oxalate precipitation, the recovery rate of neptunium is 99.91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com