Al base composite material and method for rapidly preparing TiAl base composite material plate by utilizing same

A composite material and sheet technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of slow reaction rate and long production cycle, achieve low cost, improved high temperature mechanical properties, and pollution-free preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

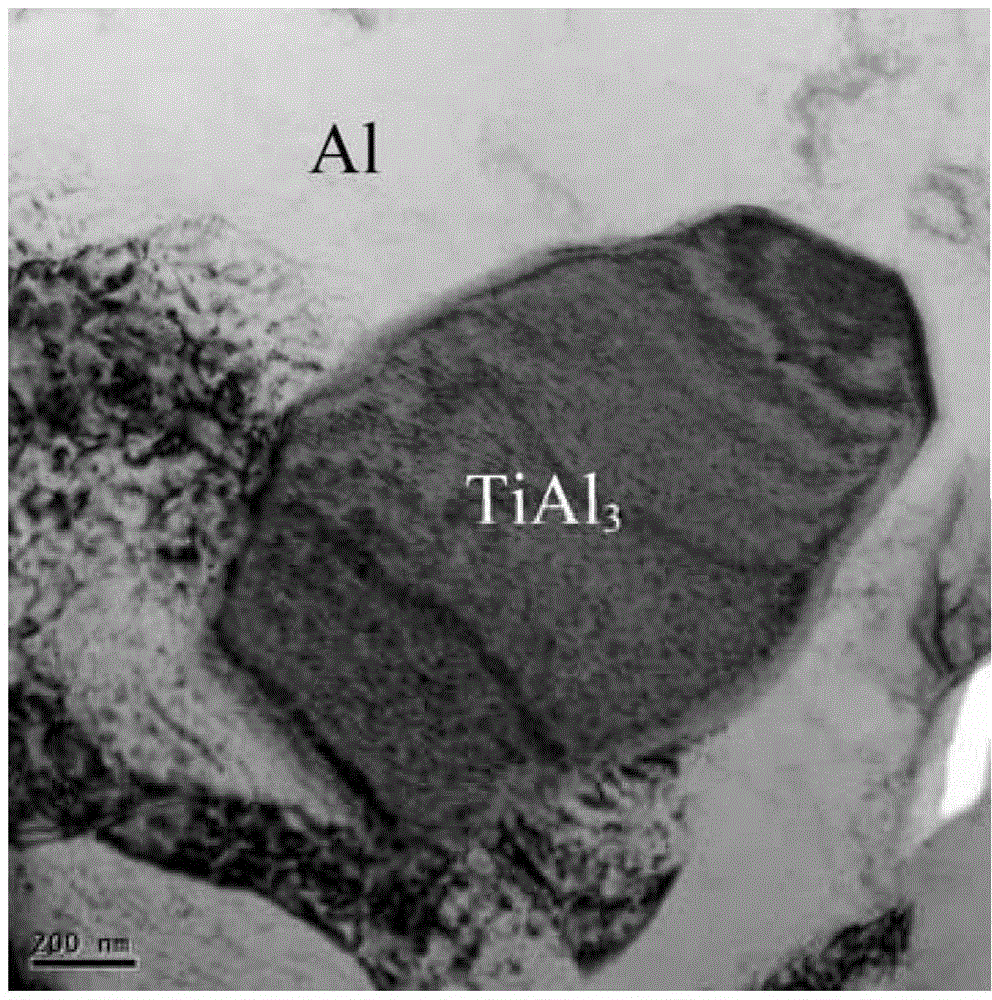

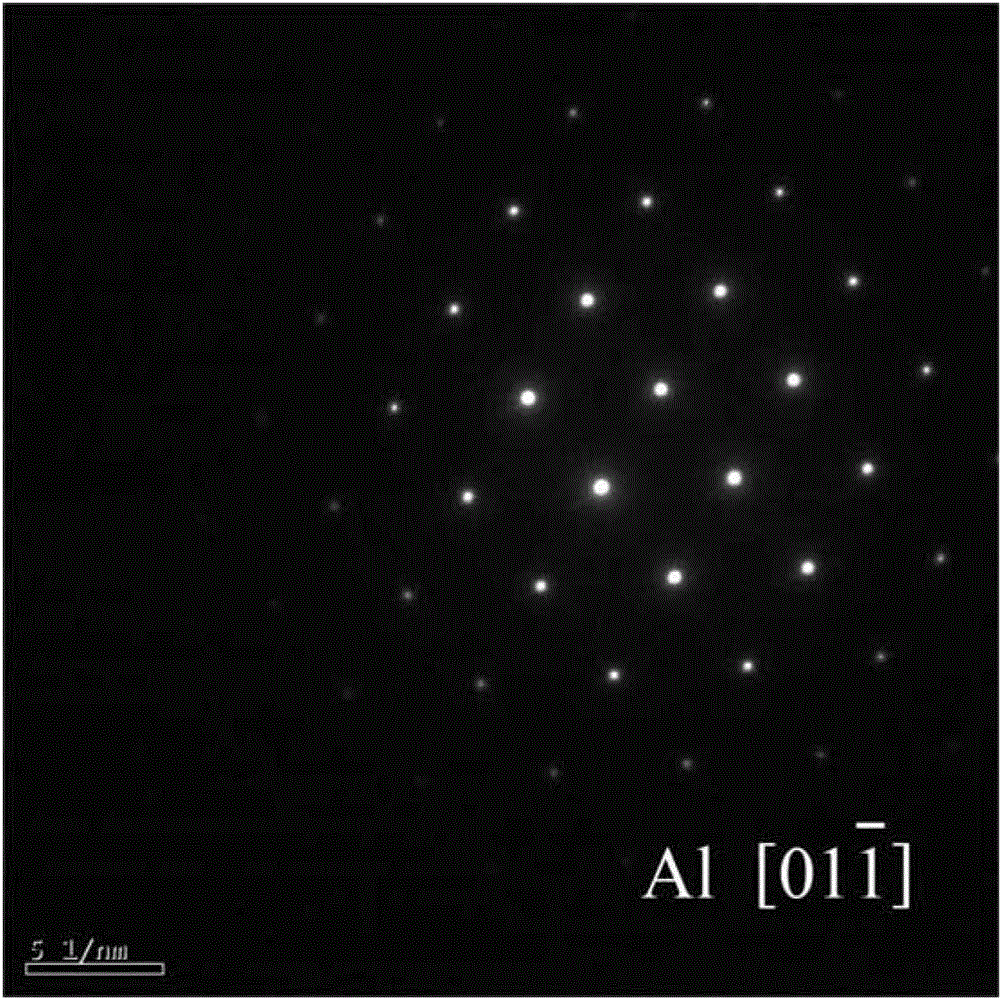

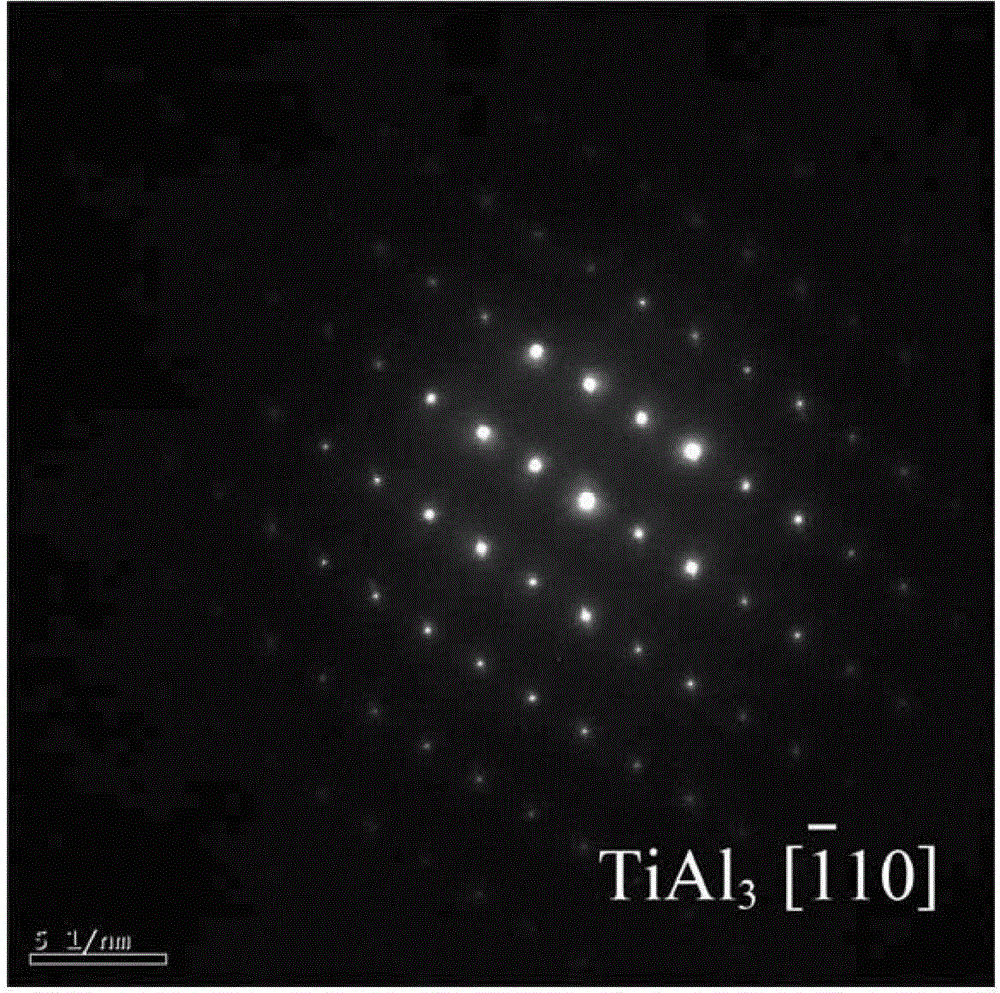

[0023] Specific Embodiment 1: In this embodiment, an Al-based composite material is made of 88%-99.9% Al and 0.1%-12% reinforcement according to the volume fraction; or an Al-based composite material is made of 85% Al-based composite material according to the mass fraction ~99.9% Al and 0.1%~15% alloying elements; the reinforcement is SiC, B 4 C. TiB 2 , TiC and Ti 5 Si 3 One or a combination of several, the alloy element is one or a combination of Ti, Si, B and Fe.

[0024] In this embodiment, by introducing alloying elements or reinforcements into Al element plates, and preparing TiAl-based composite material plates by hot pressing and reaction annealing, it can effectively improve the current production cycle of TiAl-based alloys that is too slow due to the slow reaction rate. The problem makes it possible to mass-produce TiAl-based composite sheets.

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment is different from Embodiment 1 in that: the particle size of Al is 10 μm-200 μm, and the particle size of the reinforcement is 40 nm-10 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: A method for rapidly preparing a TiAl-based composite material plate using an Al-based composite material described in Embodiment 1, specifically prepared according to the following steps:

[0027] 1. According to the thickness ratio of the pure Ti plate and the Al-based composite material described in claim 1 being 1.01 to 1.09:1, the pure Ti plate and the Al-based composite material are polished into pure Ti foil and Al-based composite material foil, The thickness of the pure Ti foil is 50 μm to 250 μm;

[0028] 2. Clean the pure Ti foil obtained in step 1 with an HF solution with a volume concentration of 5% to 20%, and clean the Al-based composite material foil obtained in step 1 with a NaOH solution with a mass concentration of 5% to 20%. Foil and Al-based composite foil were ultrasonically cleaned in acetone and dried;

[0029] 3. Place the pure Ti foil and Al-based composite material foil alternately stacked after step 2, and then perform hot press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com