Experimental device and method for measuring surface coefficient of heat transfer of supercritical carbon dioxide

A carbon dioxide and heat transfer coefficient technology, applied in the field of unconventional oil and gas exploitation, can solve the problems of less test data and complex heat transfer law of supercritical carbon dioxide, and achieve the effect of simple equipment, scientific measurement method and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

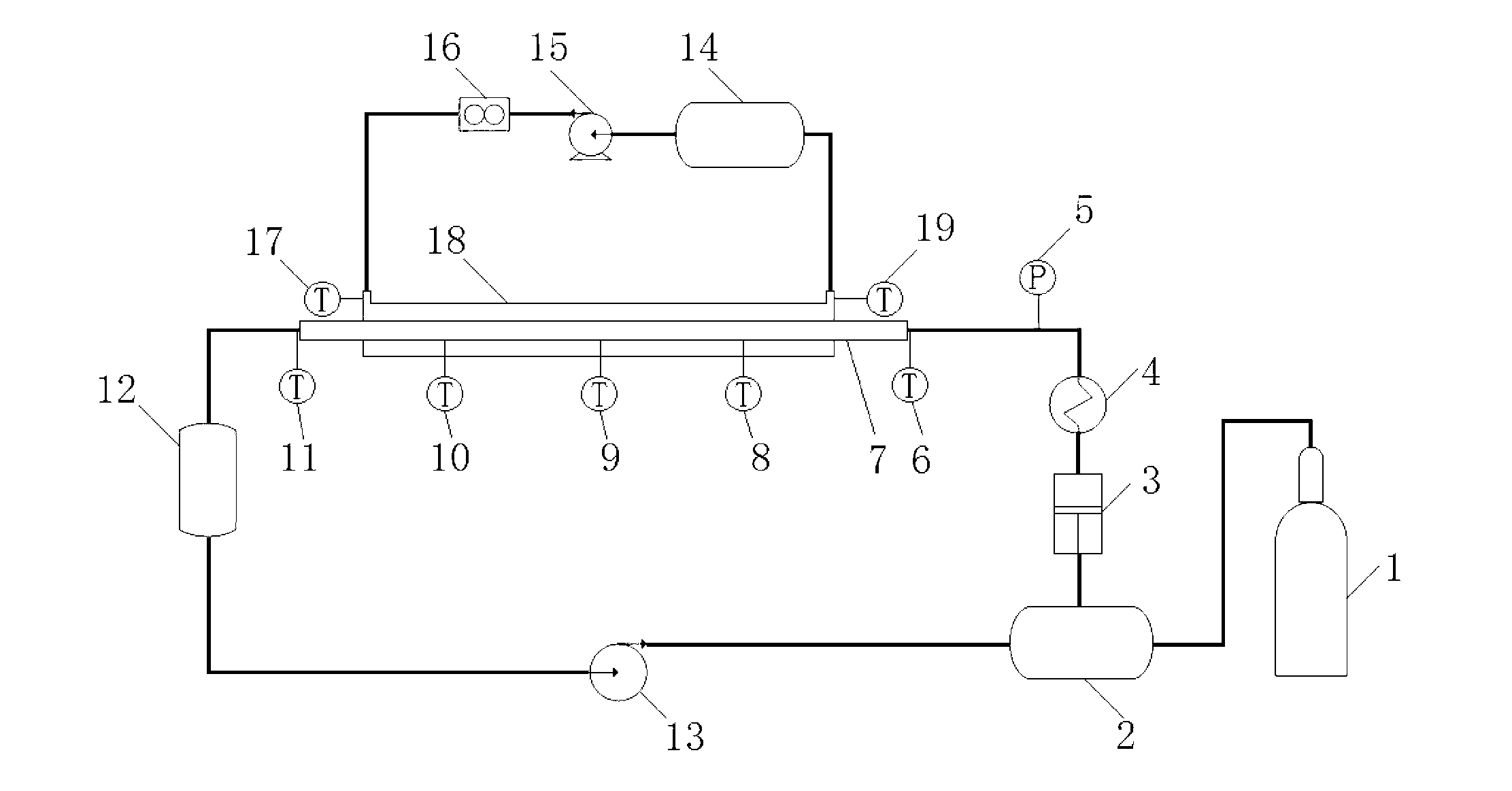

[0011] Such as figure 1 As shown, the experimental device used for the measurement of supercritical carbon dioxide surface heat transfer coefficient includes: supercritical carbon dioxide circulation system and injected water circulation system. The supercritical carbon dioxide circulation system provides carbon dioxide with a closed circulation loop under high temperature and high pressure; the injection water circulation system is used to realize the heat exchange of supercritical carbon dioxide in the inner tube of the measurement pipeline section.

[0012] Supercritical carbon dioxide circulation system, including carbon dioxide gas source 1, gas buffer tank 2, gas booster pump 3, heating system 4, inner tube 7 of the measuring pipeline section, cooling device 12 and gas circulation pump 13; gas buffer tank 2, gas booster The pressure pump 3, the heating system 4, the inner pipe 7 of the measuring pipeline section, the cooling device 12 and the gas circulation pump 13 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com