Coke high-temperature dynamic reactivity controller

A controller, reactive technology, applied in non-electric variable control, program control, computer control, etc., can solve problems such as high cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

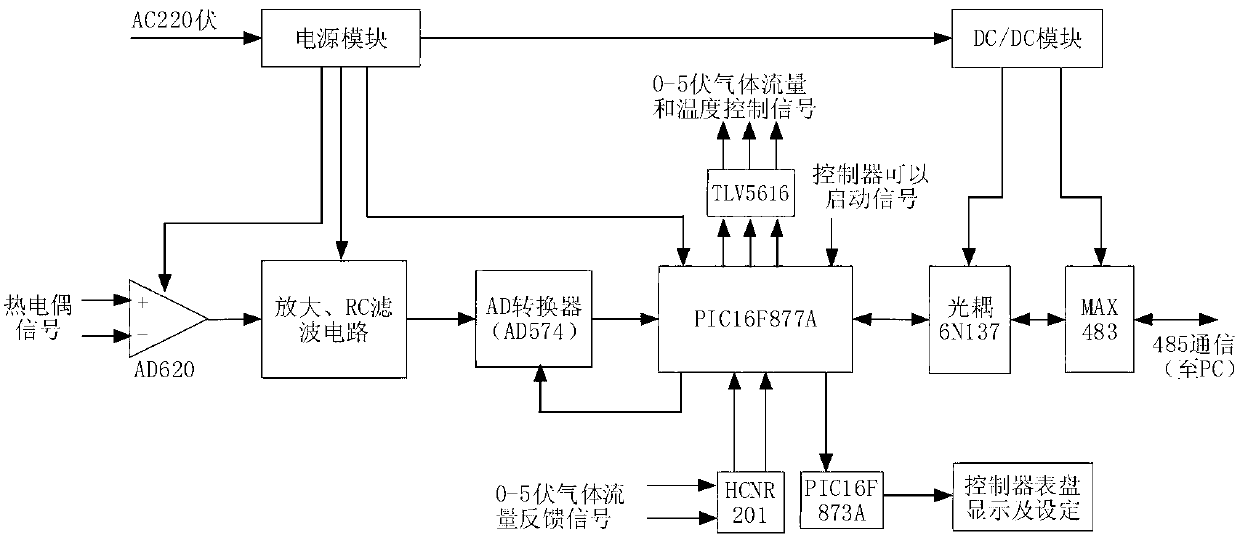

[0025] A coke high-temperature dynamic responsive controller is composed of a power supply module, DC / DC module, amplifier AD620, amplifier and RC filter circuit, AD converter, HCNR201, TLV5616, single-chip microcomputer PIC16F877A and PIC16F873A, optocoupler 6N137 and MAX483.

[0026] The specific circuit structure is:

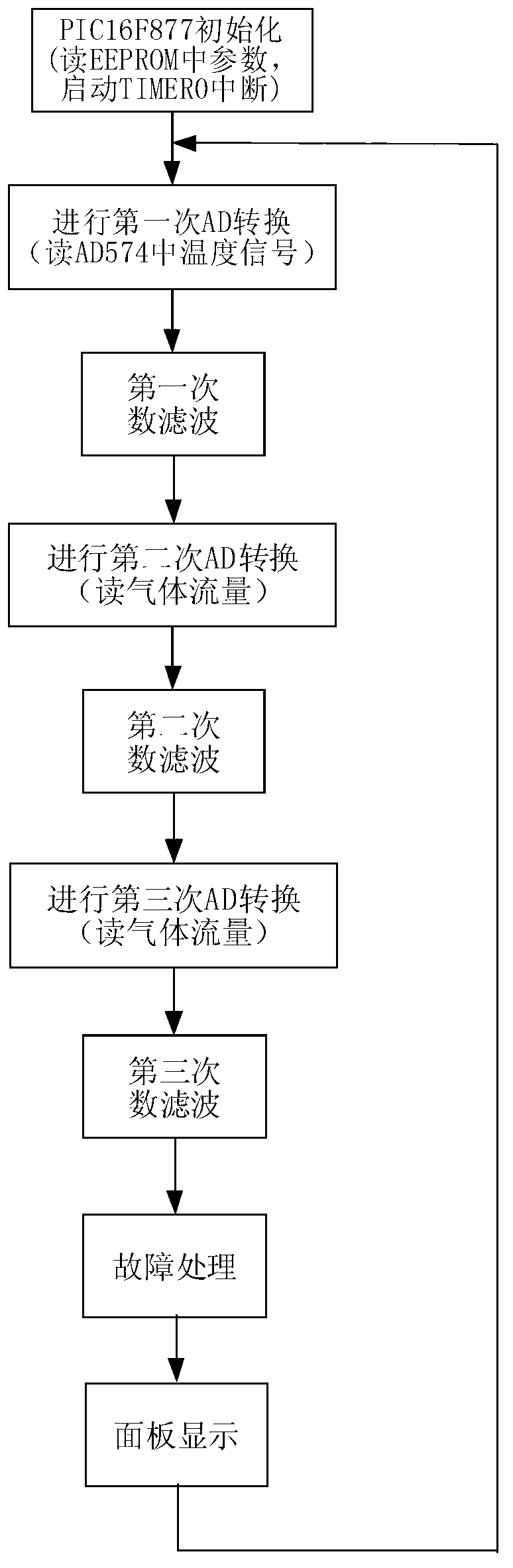

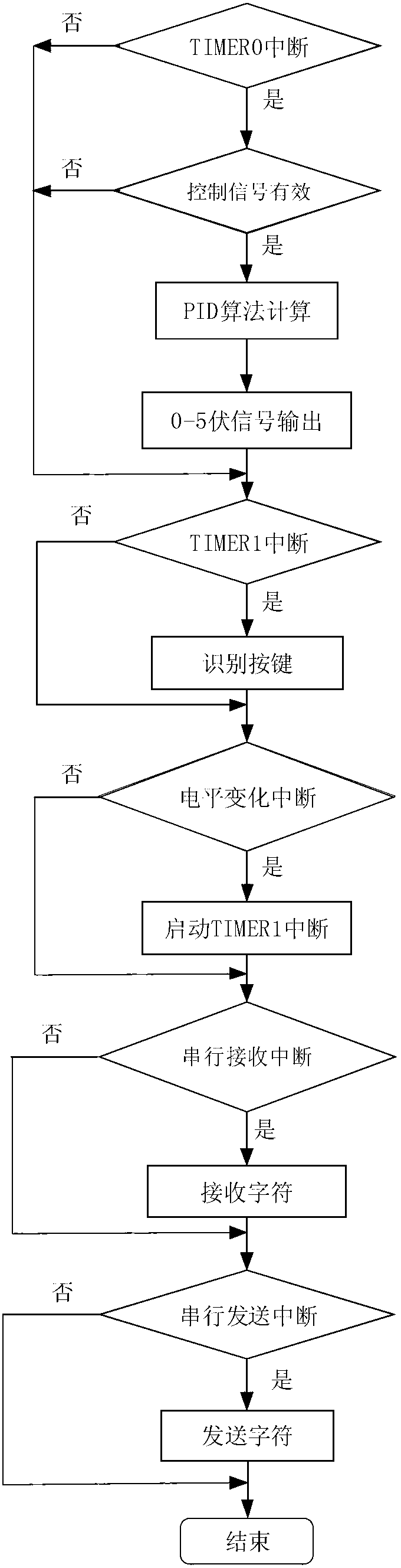

[0027] Such as Figure 13 As shown, the circuit diagram of the power module; Figure 14 Shown, DC / DC module circuit diagram; Figure 4 The circuit diagram of the amplifier AD620 is shown; Figure 5 As shown, the amplification and RC filter circuit is composed of LM358, resistors and capacitors; Figure 7 , figure 1 , figure 2 As shown, the circuit diagram of the single-chip microcomputer PIC16F877A is programmed in the single-chip microcomputer PIC16F877A; Figure 11 As shown, the optocoupler 6N137 circuit diagram; Figure 12 Shown, MAX483 circuit diagram. For thermocouple temperature measurement loops, such as Figure 6 , Figure 7 As shown, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com