Special zirconium oxychloride for coated cadmium selenide red ceramic pigment and preparation method thereof

A technology of zirconium oxychloride and ceramic pigments, applied in chemical instruments and methods, inorganic chemistry, zirconium compounds, etc., can solve problems such as no literature reports, and achieve high temperature stability, low equipment investment, and pure color tone. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

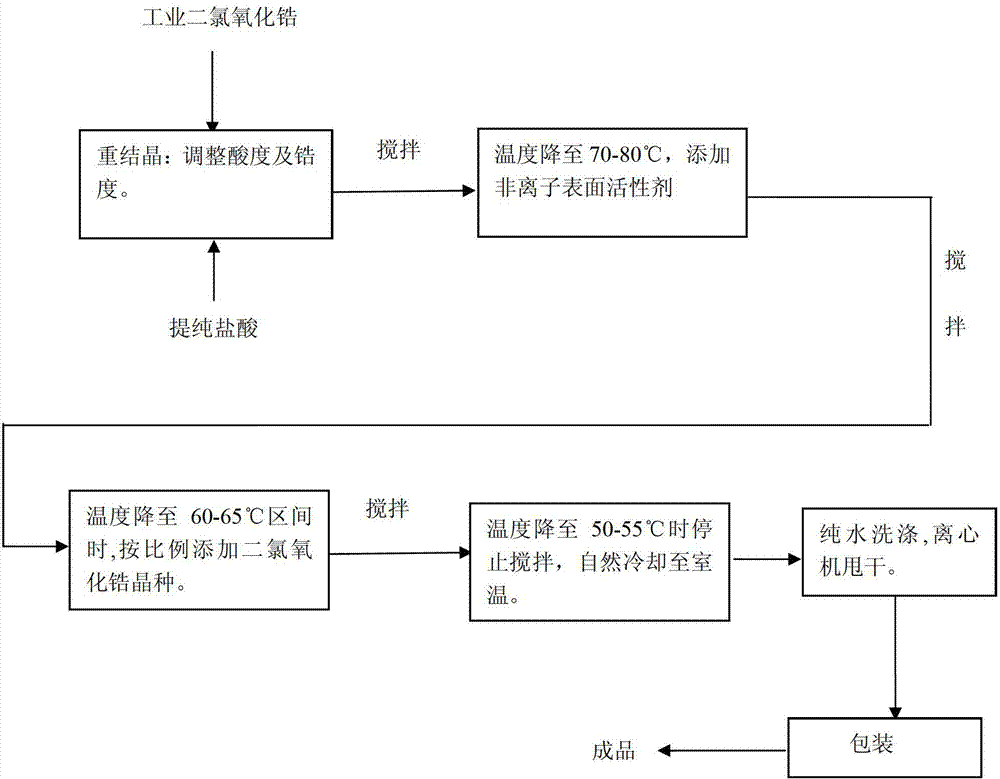

Method used

Image

Examples

Embodiment 1

[0061] Prepare the zirconium oxychloride special for the coated selenium-cadmium red ceramic pigment of the present invention according to the following steps

[0062] ①. Preparation of zirconium oxychloride crystal solution

[0063] a. Under stirring, control the dissolution temperature at 90℃, dissolve industrial zirconium oxychloride in purified hydrochloric acid with a molar concentration of 6.5, and add zirconium oxychloride to ZrO 2 The calculated concentration of zirconium oxychloride is 140g / L;

[0064] b. Cool down and add non-ionic surfactant

[0065] Under stirring, the temperature of the zirconium oxychloride crystal solution prepared in step ① is cooled to 70°C, and non-ionic polyacrylamide with a number average molecular weight of 10 million is added as a dispersant and stirred; The addition ratio is 0.05g / L,

[0066] c. Continue to cool down and add seed crystals

[0067] Step a: Add the dispersant to the solution, continue to cool down to 60°C while stirring, and add zir...

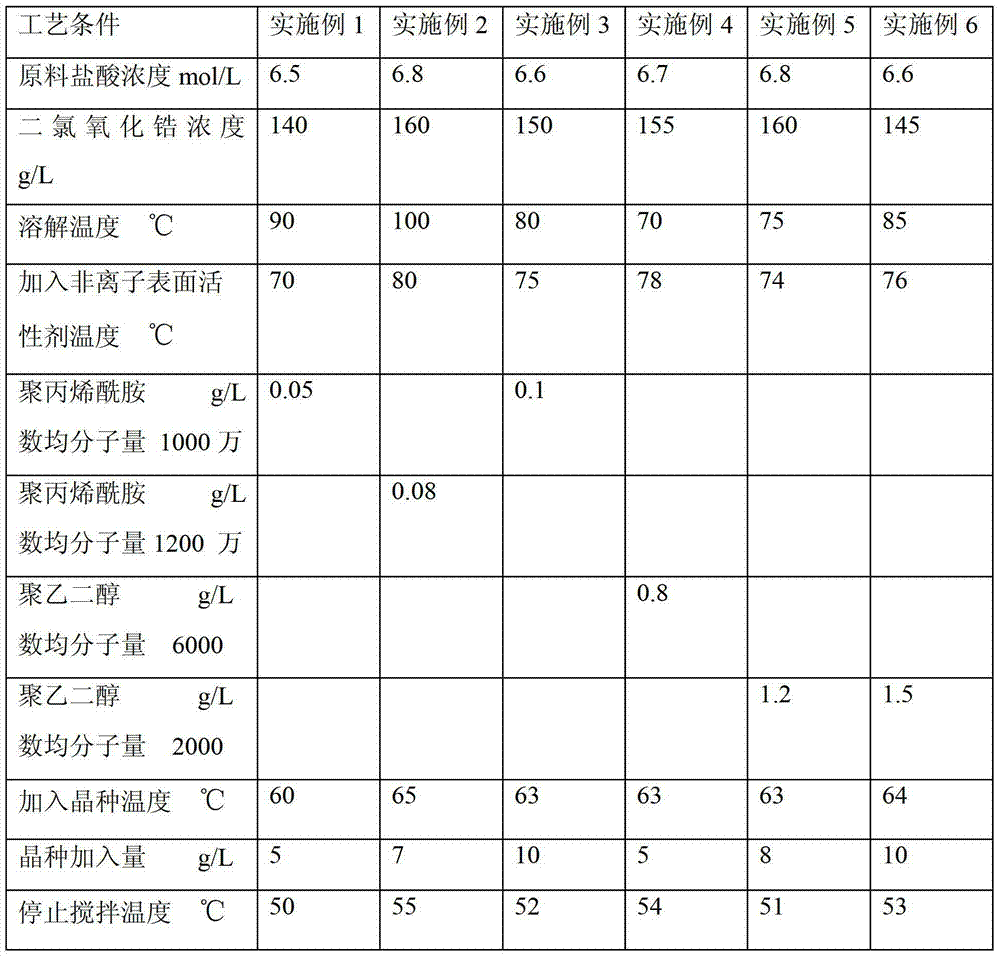

Embodiment 2~ Embodiment 6

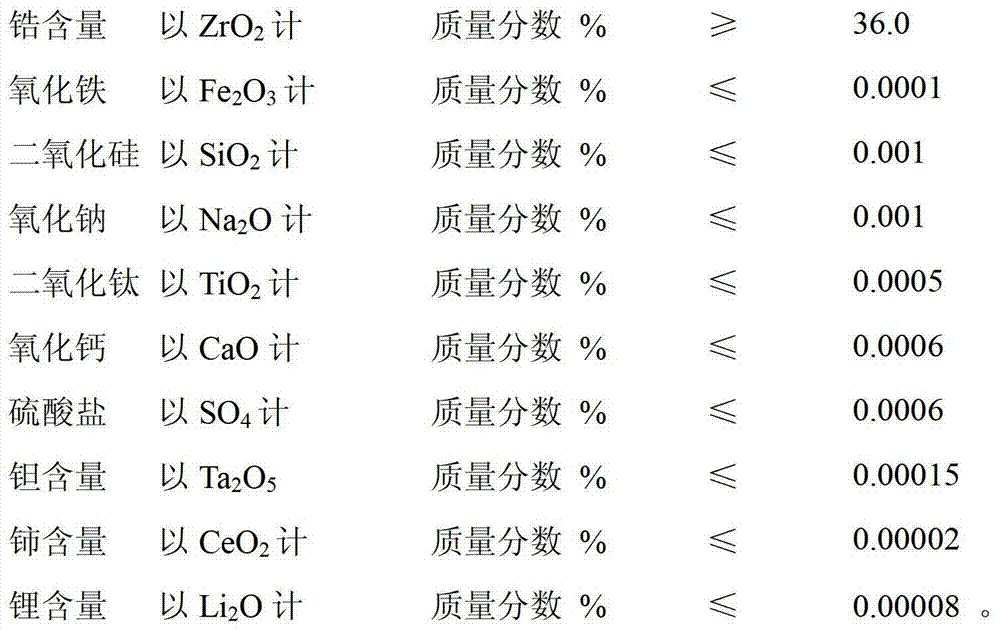

[0074] According to the method and steps of Example 1, according to the process adjustment of Table 1, the encapsulated selenium-cadmium red ceramic pigment special zirconium oxychloride of the present invention was prepared

[0075] Table 1

[0076]

[0077]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com