Double-anode electric flocculation arsenic removing method

A technology of electrocoagulation and double anode, which is applied in the field of electrochemical treatment, can solve the problems of poor air injection efficiency, low adsorption efficiency, and difficulty in controlling the injection volume, so as to improve oxidation and adsorption performance, promote oxidation and adsorption removal, and avoid energy wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

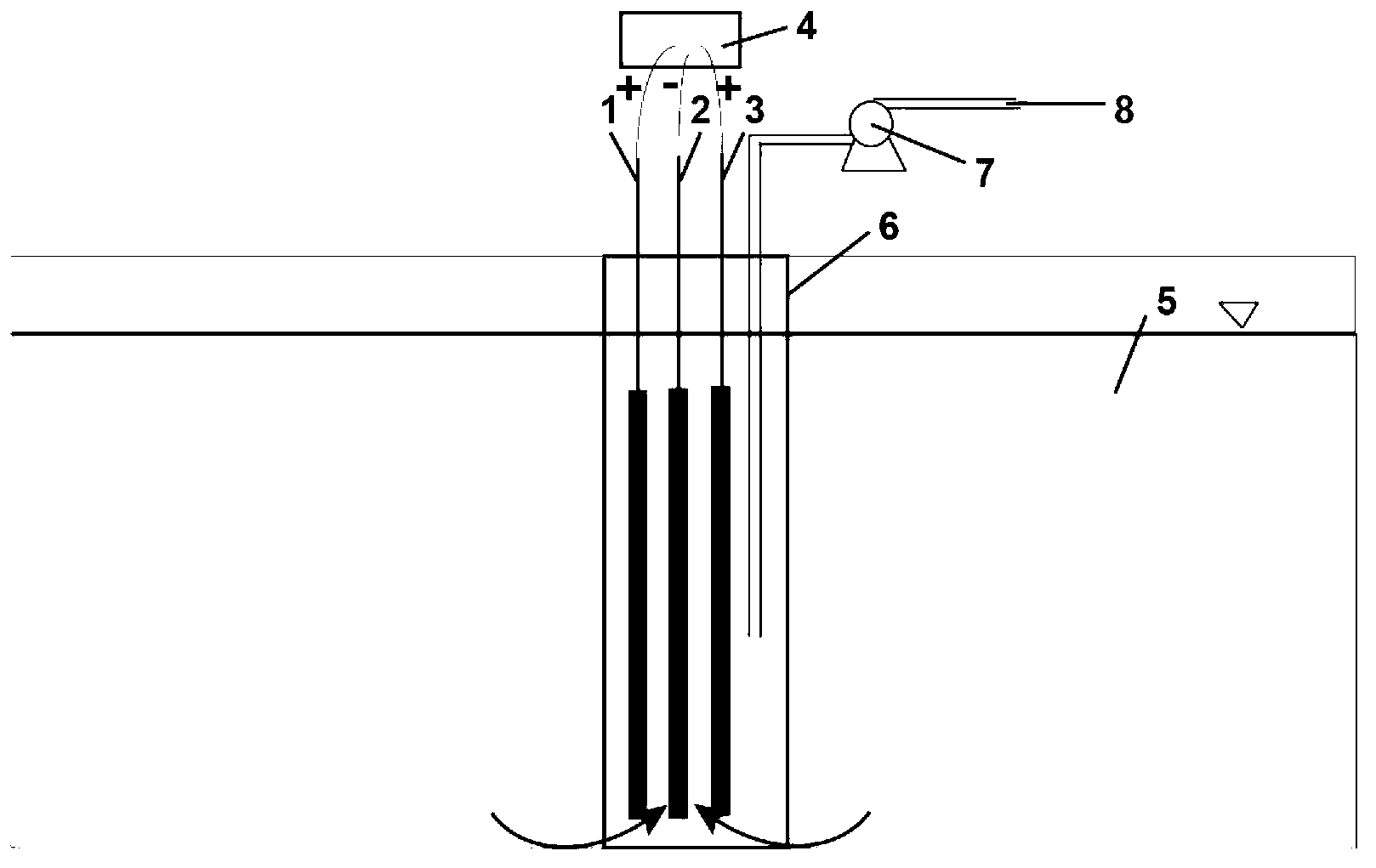

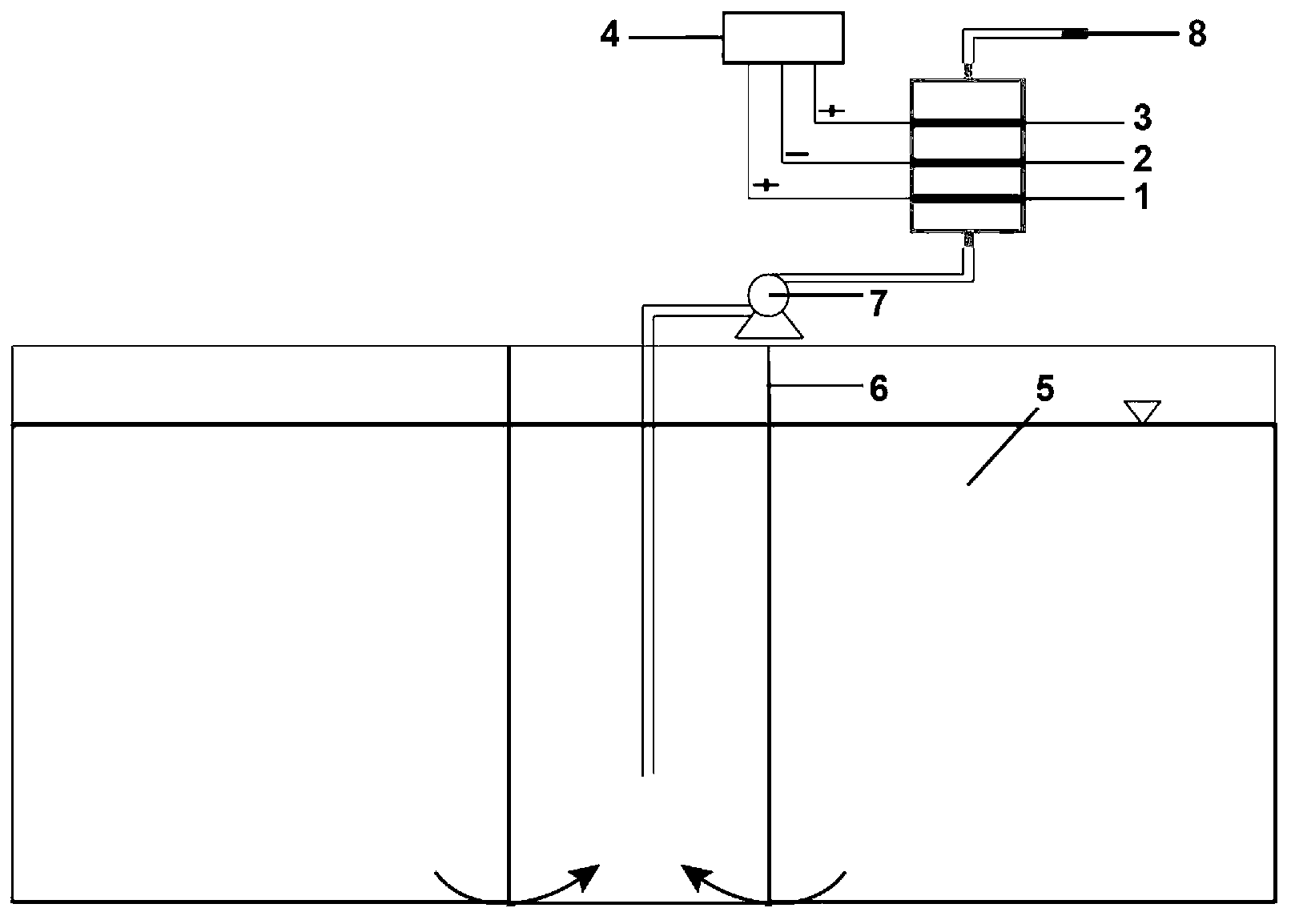

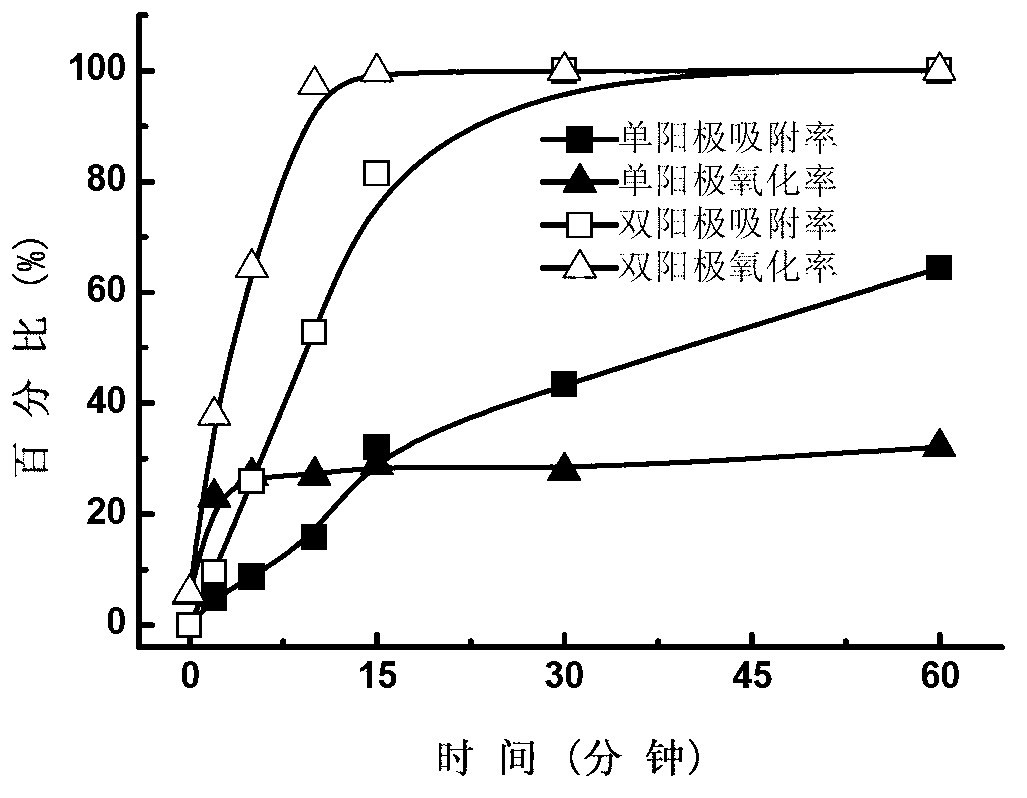

[0021] To simulate the arsenic-contaminated groundwater area in a sealed reactor, add 750ml simulated groundwater containing 500μg / L arsenic (Ⅲ) to the reactor, and use nitrogen to remove oxygen to simulate the anoxic environment in the groundwater (the initial dissolved oxygen concentration is 1mg / L or so). Insert an iron sheet (length*width*height=58*50*2mm) and two titanium-coated electrodes (length*width*height=58*50*2mm) into the reactor respectively to act as anode Ⅰ, anode Ⅱ and cathode, The cathode is located between the two anodes, and the distance between the electrodes is 4 cm. Use wires to connect the electrodes to the two output terminals of the regulated DC power supply, and adjust the power supply to control the total current to 20-100mA. The current distribution ratio between anode Ⅰ and anode Ⅱ is adjusted by a rheostat connected in series with anode Ⅰ, and the distribution ratio is controlled between 1:0-1:1 according to the actual dissolved oxygen content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com