Polyurethane diolame controlled-release fertilizer containing herbicide and preparation method thereof

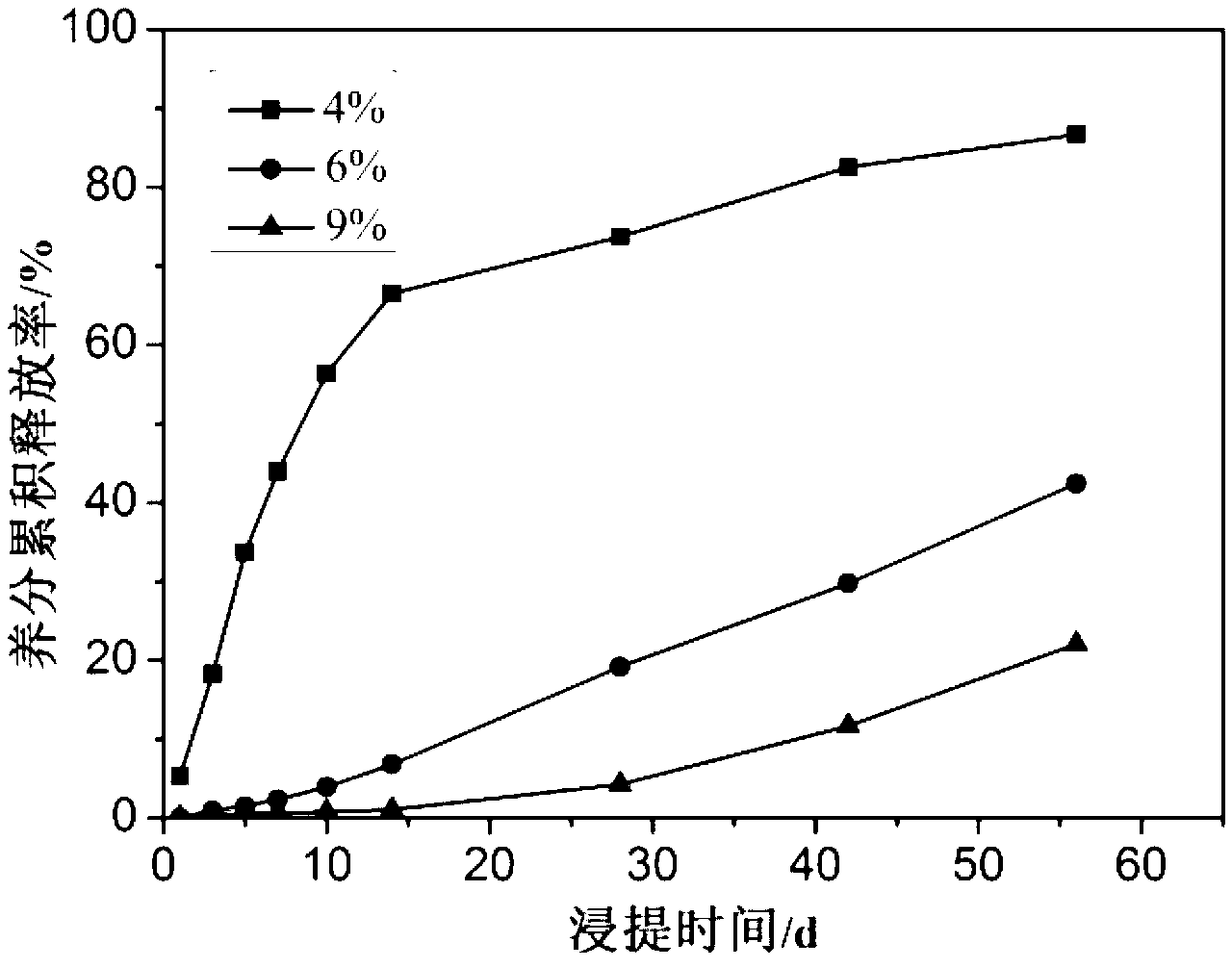

A technology for controlled-release fertilizers and herbicides, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of increasing and weakening of herbicidal effects, and achieve the effects of inhibiting growth, excellent controlled-release performance, and good promotion prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 1 kg of compound fertilizer particles with a particle size of 3 to 4 mm, and place them in a water chestnut sugar coating machine with a diameter of 400 mm. Turn on the rotary switch and heating switch of the sugar coating machine to preheat the fertilizer. The speed of the sugar coating machine is 46r / min. Until the fertilizer temperature reaches 75℃ and keep it warm;

[0028] Weigh 12.5g castor oil, 0.8g butachlor, 0.6g microcrystalline paraffin to form coating liquid A, and heat to 75℃ to melt microcrystalline paraffin completely; Weigh 6.1g polymethylene polyphenyl polyisocyanate , Which is the coating liquid B, heated to 75°C. The mass ratio of the polyol in the coating liquid A to the isocyanate in the coating liquid B is 2.05:1. The coating liquids A and B are sprayed onto the surface of the fertilizer particles simultaneously by spraying, and the temperature is maintained at 75°C for in-situ polymerization and curing for 6 minutes, and the surface of the fer...

Embodiment 2

[0030] Weigh 1 kg of compound fertilizer particles with a particle size of 3 to 4 mm, and place them in a water chestnut sugar coating machine with a diameter of 400 mm. Turn on the rotary switch and heating switch of the sugar coating machine to preheat the fertilizer. The speed of the sugar coating machine is 46r / min. Until the fertilizer temperature reaches 80℃ and keep it warm;

[0031] Weigh 13g castor oil, 1g butachlor and 0.7g microcrystalline paraffin to form coating liquid A. Heat to 80°C to melt microcrystalline paraffin completely; weigh 5.3g polymethylene polyphenyl polyisocyanate, that is It is the coating liquid B, heated to 80°C. The mass ratio of the polyol in the coating liquid A to the isocyanate in the coating liquid B is 2.45:1. The uniformly heated coating liquids A and B were sprayed onto the surface of the fertilizer particles at the same time by spraying, and the temperature was maintained at 80°C for in-situ polymerization and curing for 6 minutes. The ...

Embodiment 3

[0033] Weigh 1 kg of compound fertilizer particles with a particle size of 3 to 4 mm, and place them in a water chestnut sugar coating machine with a diameter of 400 mm. Turn on the rotary switch and heating switch of the sugar coating machine to preheat the fertilizer. The speed of the sugar coating machine is 46r / min. Until the fertilizer temperature reaches 85℃ and keep it warm;

[0034] Weigh 14g castor oil, 1.4g butachlor, 1.1g microcrystalline paraffin to form coating liquid A, heat it to 85°C to completely melt microcrystalline paraffin; weigh 6g polymethylene polyphenyl polyisocyanate, that is For coating liquid B, heat to 85°C. The mass ratio of polyol in coating liquid A to isocyanate in coating liquid B is 2.33:1. The uniformly heated coating liquids A and B are sprayed onto the surface of the fertilizer particles at the same time by spraying, and the temperature is maintained at 85°C for in-situ polymerization and curing for 5 minutes. The surface of the fertilizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com