Foaming agent for EPDM sponge rubber

A technology of sponge rubber and foaming agent, applied in the field of foaming agent for EPDM sponge rubber, can solve the problems of affecting the performance of rubber products, low technical quality level, unstable quality, etc., to achieve good temperature adaptability and dispersion uniformity, The effect of low density and low cost

Inactive Publication Date: 2013-09-25

中山市红喜橡塑五金制品有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the foaming agent used in EPDM sponge rubber has problems such as low foaming ratio and poor stability, which directly affects the performance of rubber products, resulting in low product strength, unstable quality, and low overall technical quality.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

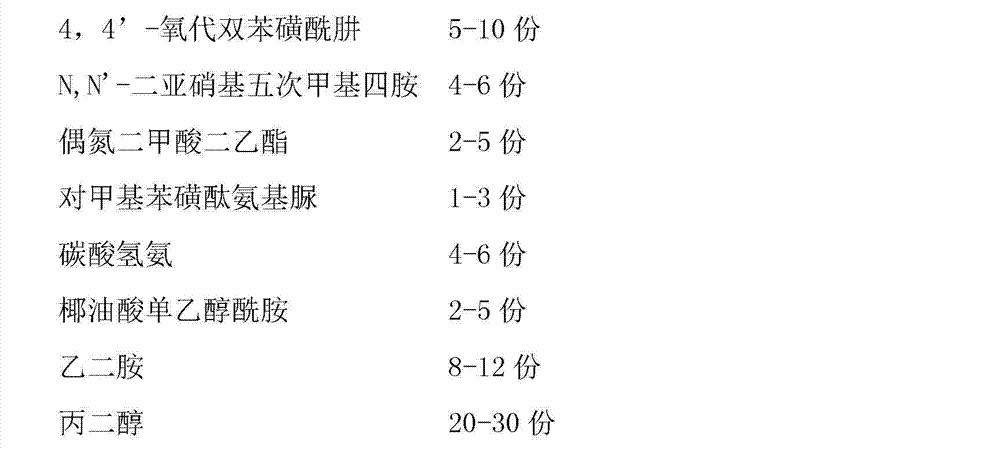

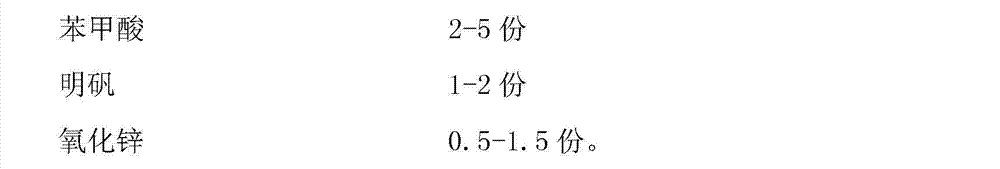

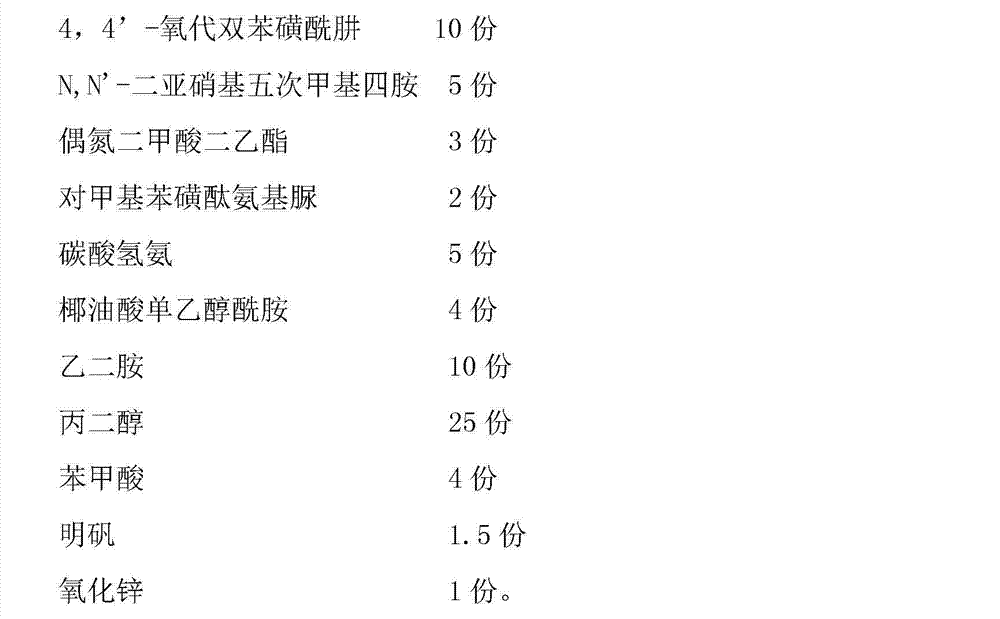

[0015] A kind of blowing agent for EPDM sponge rubber, is made up of the raw material of following weight part:

[0016]

[0017]

[0018] Using the foaming agent of the present invention as the foaming system for preparing EPDM foaming materials, the rubber material was prepared according to the basic experimental formula, and molded and foamed at 180°C to test its performance, see Table 1 below for details.

[0019] Table 1

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A foaming agent for an EPDM sponge rubber is disclosed by the invention, and consists of the following raw materials in parts by weight: 5-10 parts of 4, 4'-oxybis(benzenesulfonyl hydrazide), 4-6 parts of N,N'-dinitroso pentamethylene tetramine, 2-5 parts of diethyl azodiformate, 1-3 parts of p-toluenesulfonyl semicarbazide, 4-6 parts of ammonium bicarbonate, 2-5 parts of coconut oil monoethanolamide, 8-12 parts of ethylenediamine, 20-30 parts of propylene glycol, 2-5 parts of benzoic acid, 1-2 parts of alum, and 0.5-1.5 parts of zinc oxide. The foaming agent of the invention is excellent in foaming power, high in foaming ratio, steady in process, low in cost and convenient to use, and the generated foams has good temperature adaptability and disperse uniformity. The EPDM sponge rubber material prepared by the foaming agent is good in mechanical properties, low in density, fine in micropore and uniform in dispersion.

Description

technical field [0001] The invention relates to a foaming agent, in particular to a foaming agent for EPDM sponge rubber. Background technique [0002] Sponge rubber is a general term for various rubbers with a porous structure, and is generally made by foaming with a chemical foaming agent. Because the microporous structure has both the typical characteristics of solid and gas, the sponge rubber with microporous structure has small mass, good heat insulation, sound insulation, performance and mechanical damping properties. Sponge rubber is mainly used in the manufacture of automobiles [0003] Windshield strips, buffer rubber pads, sealing gaskets for construction projects, heat insulation materials for weak current components, shock absorbing materials, simple diving suits and rubber shoes and other products. EPDM sponge rubber has been widely used as sealing and heat insulation materials in the automobile industry and construction industry in recent years because of its...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/16C08J9/10C08J9/08

Inventor 鲁奎

Owner 中山市红喜橡塑五金制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com